Method for improving binding force of two-phase materials of pentamode metamaterial in additive manufacturing

A technology of metamaterials and binding force, applied in manufacturing tools, additive manufacturing, additive processing, etc., can solve the problems of increased design complexity and additive manufacturing difficulty, unsatisfactory acoustic effect control, and poor comprehensive mechanical properties , to simplify the preparation and design process, shorten the process and cycle, and achieve the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

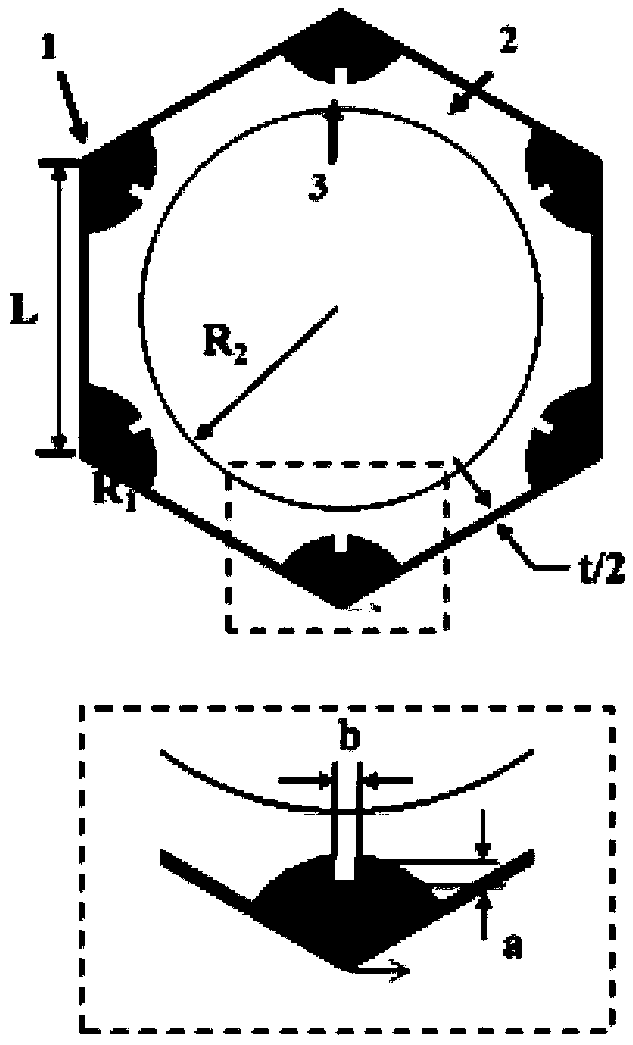

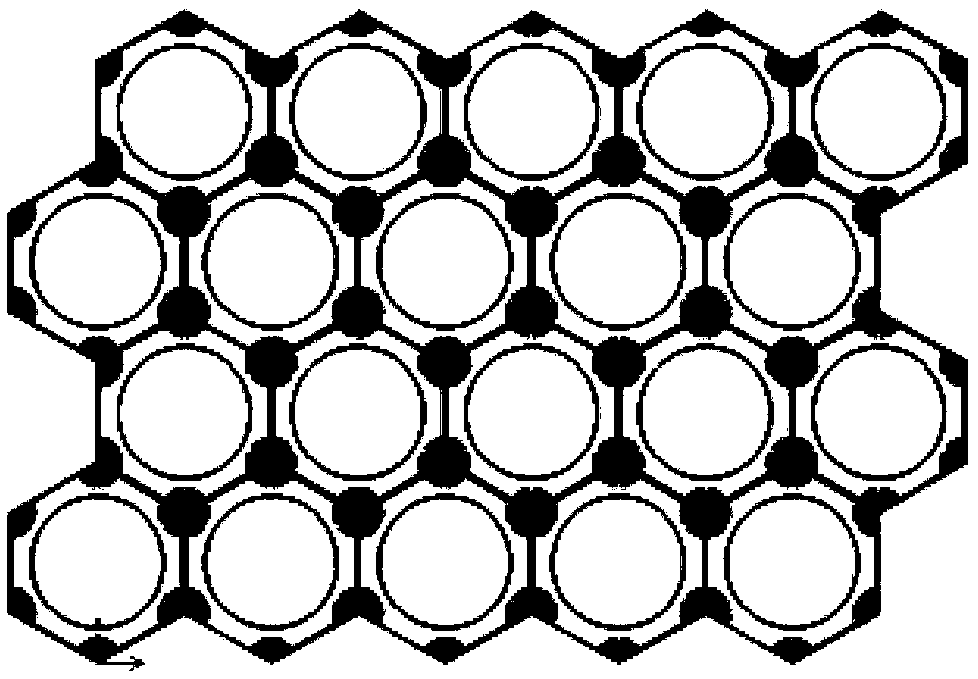

[0060] This is to use the present invention to manufacture Ti6Al4V-based five-mode metamaterial parts, adding a non-metallic rubber layer inside. The honeycomb structure has typical engineering applications in acoustic functional devices, such as medical stethoscopes, ultrasonic flaw detection, etc., and is also used in common applications in daily life, such as the sound insulation and noise reduction walls of KTV rooms. The preparation and forming of titanium alloy / nylon multi-material frame structure by laser selective melting technology and fusion deposition technology is taken as an example.

[0061] Ti6Al4V is a near-alpha titanium alloy, which is widely used in the fields of biomedicine and marine ships due to its ultra-high specific strength, excellent corrosion resistance and biocompatibility. In this example, the matrix adopts the evolution form of the honeycomb model, and the specific steps are as follows:

[0062] (1) Using Ti6Al4V alloy as the forming matrix mate...

example 2

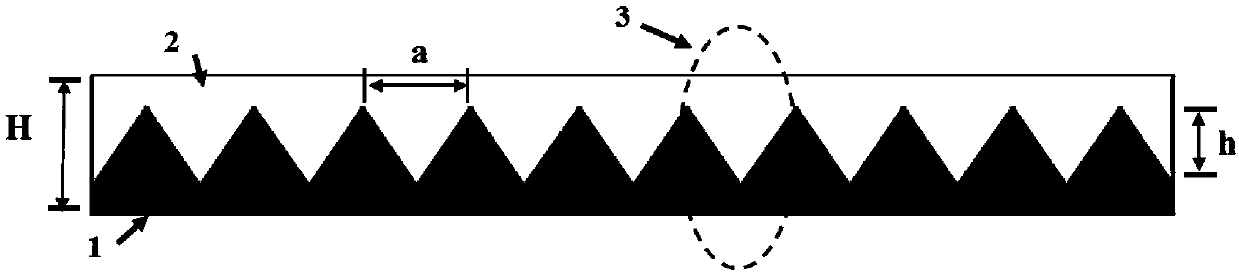

[0069] Using the present invention to manufacture an AlSi10Mg-based five-mode metamaterial interface structure, the lower layer is an AlSi10Mg alloy, and the upper layer is a rubber material. The magnesium alloy / rubber multi-material frame structure is prepared and formed by laser selective melting technology and fusion deposition technology. The specific steps are as follows:

[0070] (1) AlSi10Mg is set as the forming matrix material, its elastic modulus E is 74.35GPa, and its density ρ is 2600kg / m 3 , establish the sawtooth interface structure as shown in the figure, the overall boundary height in the figure is H, the distance between the sawtooth is a, the non-sawtooth thickness is h, and figure 2 The metal phase is Ti6Al4V alloy, and the non-metal phase is rubber material.

[0071] (2) According to the established three-dimensional CAD model, export the STL file, and use the SLM process to manufacture the base structure;

[0072] (3) Manufacture of metal substrates by s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com