Sludge treatment system and method

A sludge treatment and sludge technology, applied in the field of self-heating sludge treatment system, can solve the problems of excessive flue gas and dust in fluidized fluidized furnace, difficulty in drying municipal sludge, and high drying cost, so as to reduce the degradation of sludge organic matter, reduce Sewage discharge volume, effect of improving flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

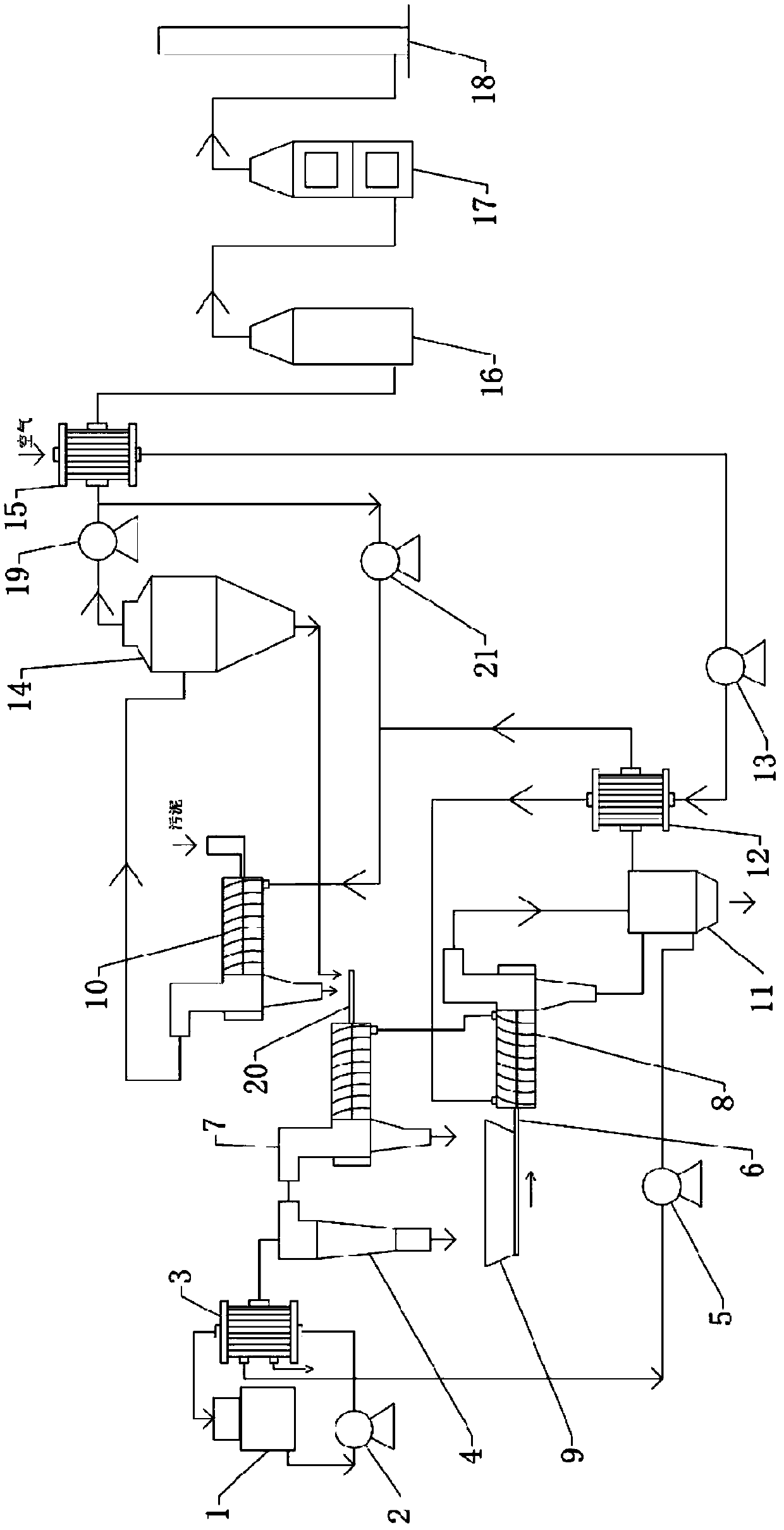

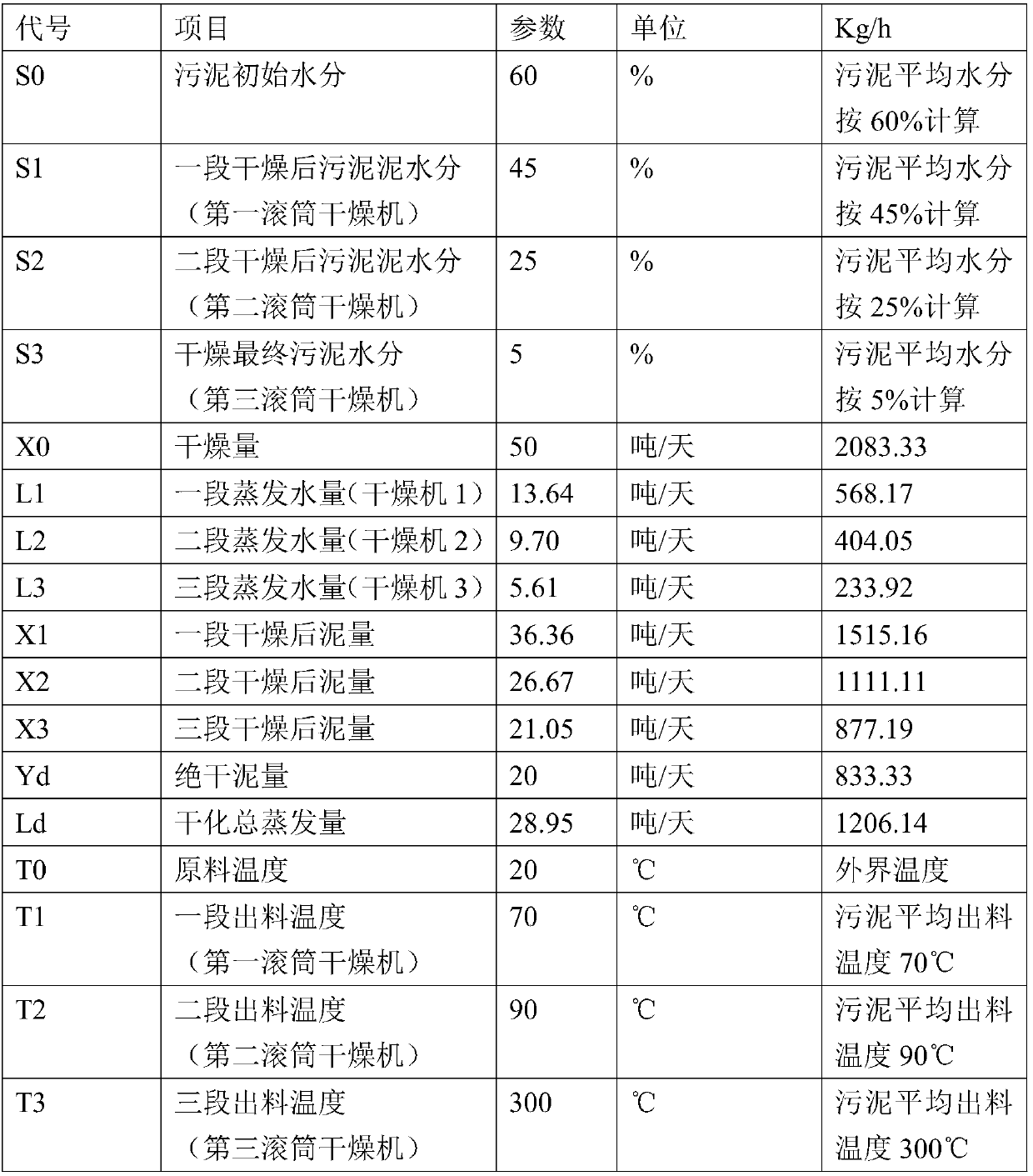

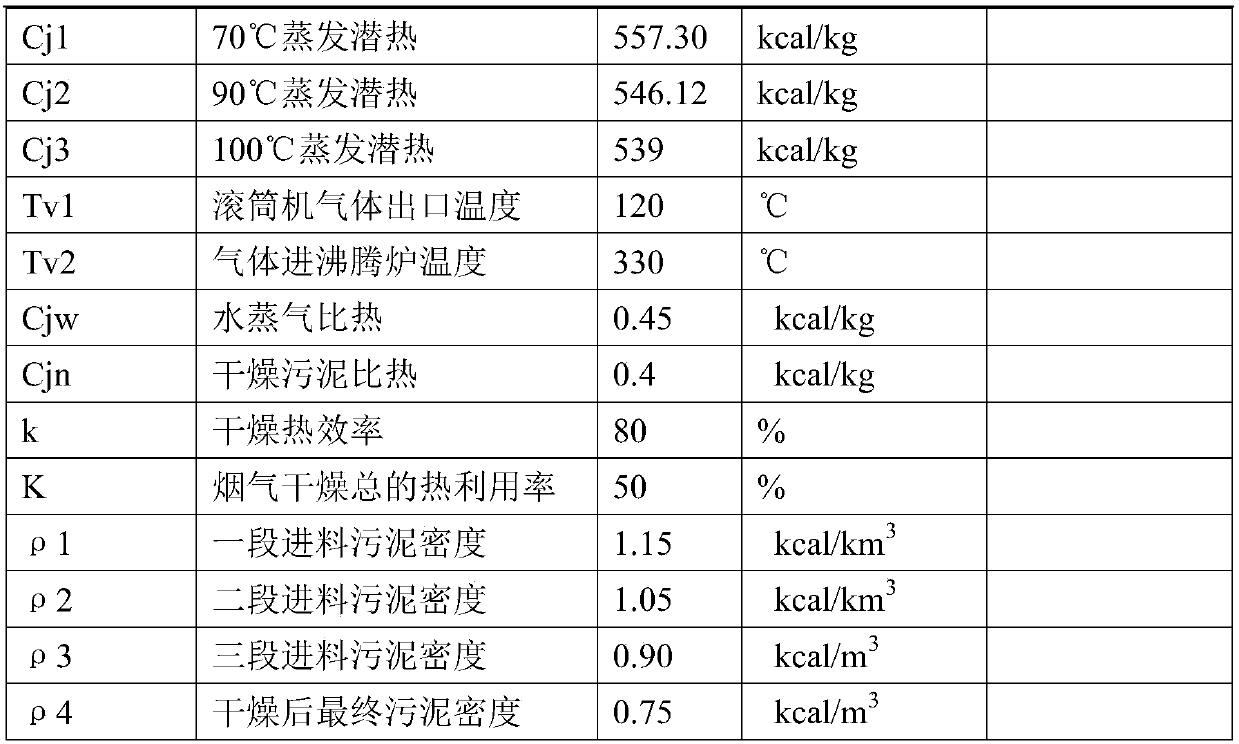

[0032] Such as figure 1 As shown, a sludge treatment system includes a first drum dryer 10, a second drum dryer 7, a third drum dryer 8, a fluidized fluidized furnace 11, a first heat exchanger 12, and a second heat exchanger 15. The third drum dryer is a jacketed drum dryer;

[0033] The discharge port of the first drum dryer 10 communicates with the feed port of the second drum dryer 7, the discharge port of the second drum dryer communicates with the feed port of the third drum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com