System of utilizing waste heat of high-aluminum coal and gangue calcined kaolin

A technology for calcining kaolin and coal gangue, which is applied in steam generation methods using heat carriers, waste heat treatment, and energy efficiency improvement, and can solve problems such as coal gangue pollution, achieve the effects of reducing surface temperature, strengthening cooling, and realizing waste heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

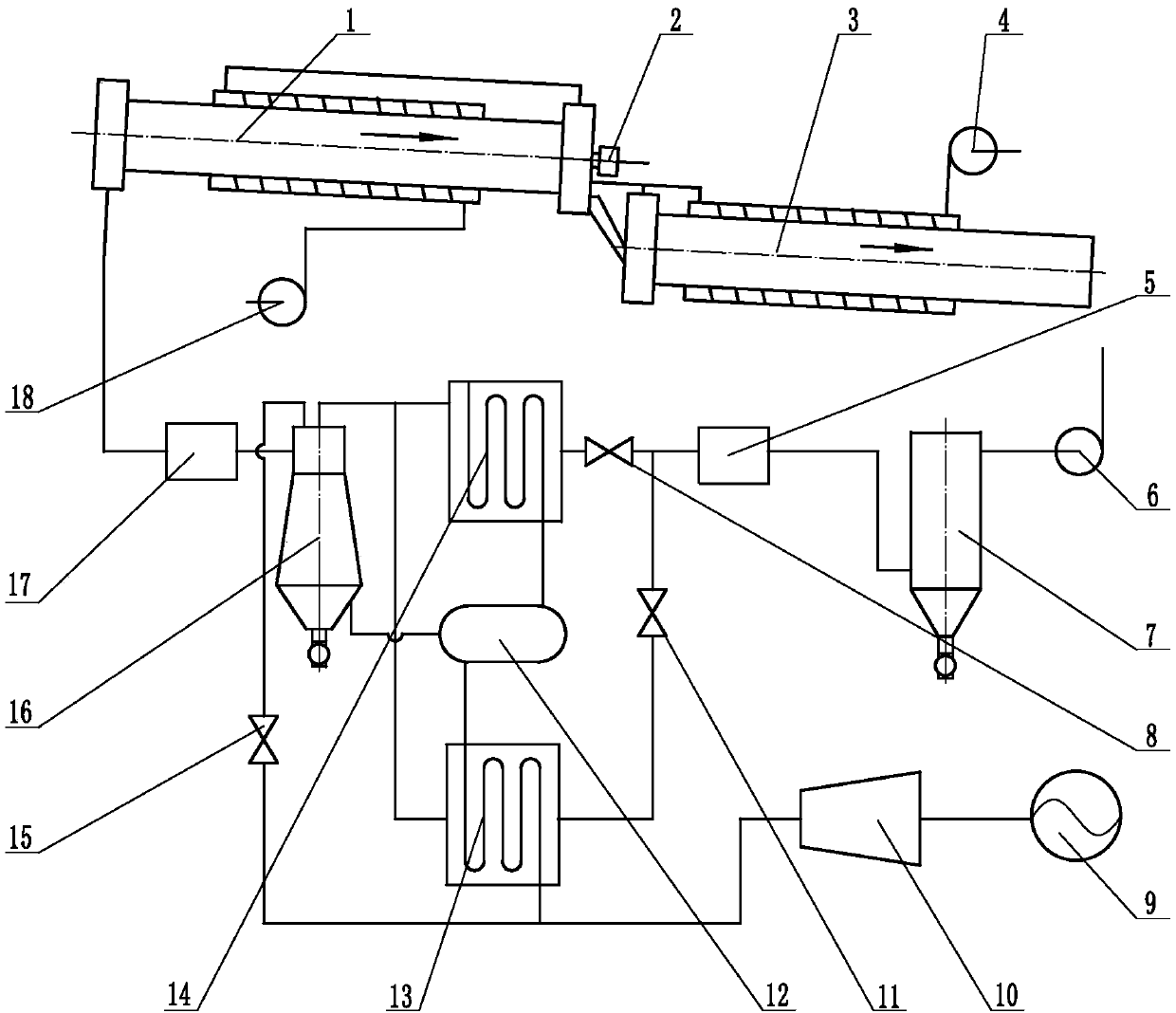

[0029]A high-aluminum coal and coal gangue calcined kaolin waste heat utilization system, including a calcining device, a cooling device, a denitrification device, a first dust removal device, a steam generator, a steam turbine unit, a generator unit, a desulfurization device, a second dust removal device, and a first fan , the calcination device is provided with a feed port and a discharge port, the calcination device is connected to the denitrification device through the flue gas pipeline on the side of the feed port, the denitrification device is connected to the first dust removal device through the pipeline, and the first dust removal device is connected to the steam generation through the pipeline. The steam generating device is connected to the steam turbine unit through the pipeline, the steam turbine unit is connected to the generator set, the steam generating device is connected to the desulfurization device through the flue gas pipeline, the desulfurization device is ...

Embodiment 2

[0032] Such as figure 1 As shown, a high-alumina coal and coal gangue calcined kaolin waste heat utilization system, the calcining device is a horizontal calcining device 1, and a burner 2 is provided at the discharge end of the horizontal calcining device 1.

[0033] Described cooling device is horizontal cooling device 3, and the feed inlet of horizontal cooling device 3 links to each other with the discharge port of calcination device, and cold air enters from the discharge end of horizontal cooling device 3, and from the outlet of horizontal cooling device 3 The feed end enters the discharge end of the calcining device 1 .

[0034] The horizontal cooling device 3 includes a cooling cylinder and a second fan 4. Heat exchange blades are welded on the outer wall of the cooling cylinder. The heat exchange blades are provided with a sheath outside. A closed airtight space is formed between the outer wall of the cooling cylinder and the sheath. The interlayer, the second fan 4 ...

Embodiment 3

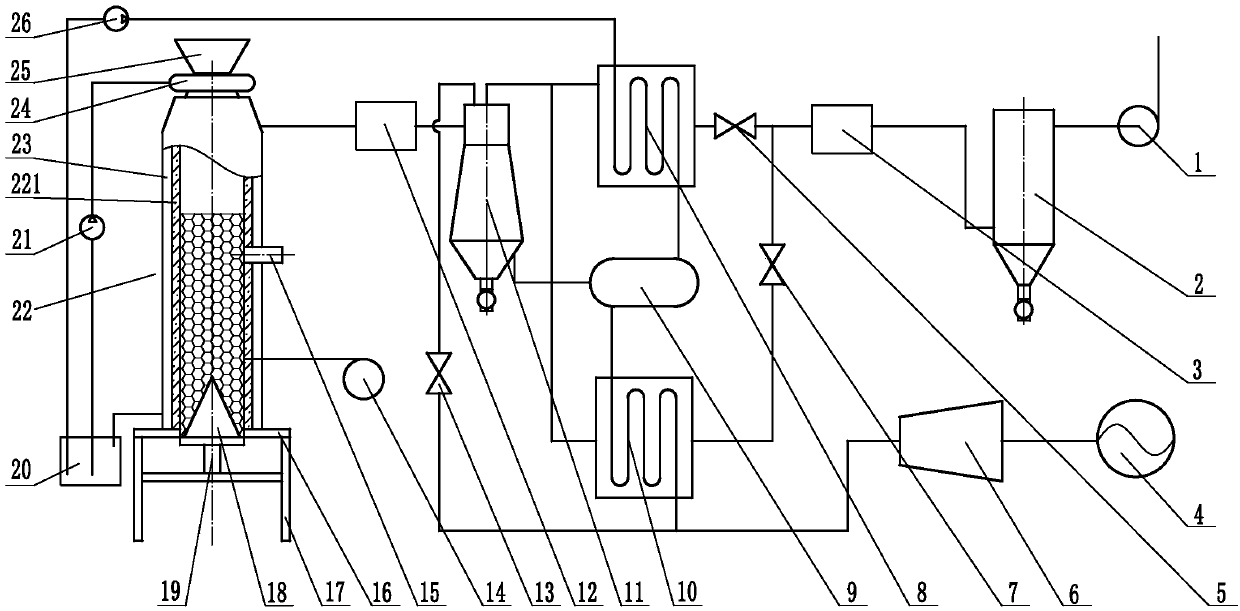

[0043] figure 2 It is a waste heat utilization system for calcining kaolin with high alumina coal and coal gangue using a vertical calcination device.

[0044] The calcining device is a vertical calcining device 22, comprising a calcining device housing 221, the lower part of the calcining device housing 221 is connected to the base 16, the upper part of the calcining device housing is provided with a feeding port 25, and the lower part is provided with a discharge port. The lower part of the feed opening is provided with a lifting seat 18, and the lifting seat 18 is connected with the lifting seat driving device 19, and the lifting seat driving device 19 is connected with the base, and the base is connected with the supporting legs 17 of the bottom. The gap between the lifting seat 18 and the discharge port is adjusted by the lifting seat driving device 19, and a burner 15 is arranged at an upper position close to the height direction of the calcination device shell, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com