Transparent soil based on 3D printing transparent soil particle material and preparation method thereof

A 3D printing, granular material technology, applied in the field of geotechnical engineering visualization model test, can solve the problems of affecting the refractive index of calcium bromide solution, low purity of fused silica sand, easy precipitation of calcium bromide crystals, etc. Visualization, the effect of good optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment discloses a transparent soil based on 3D printing transparent soil particle material, including transparent solid material and pore liquid.

[0030] The transparent solid material adopts 3D printed transparent soil particles. The printing material of the transparent soil particles is selected from photosensitive resin. The particle diameter of the transparent soil particles is 1.5-2.5 mm, the refractive index is 1.51-1.52, and the specific gravity is 1.10-1.12.

[0031] The pore liquid is a mixed liquid of small molecule benzyl silicone oil and n-dodecane. The refractive index of the pore liquid is the same as that of the transparent earth particles.

[0032] The transparent soil particles are mixed with pore liquid to form artificially synthesized transparent soil.

Embodiment 2

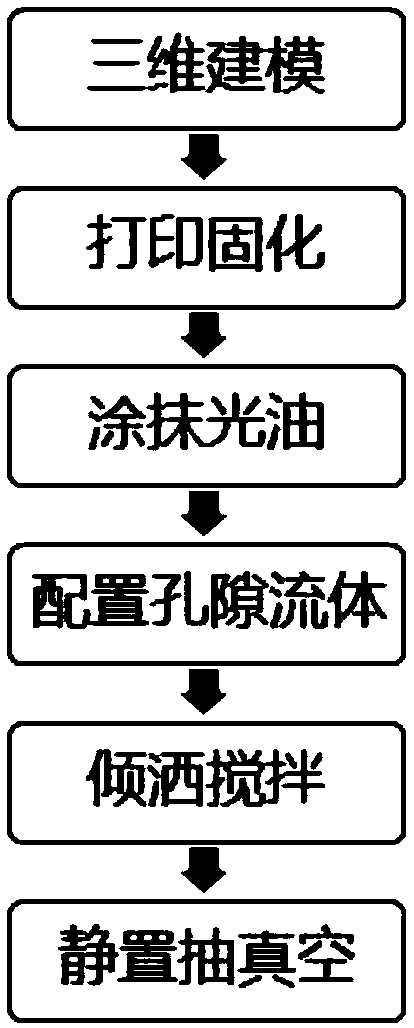

[0034] see figure 1 , this embodiment discloses a method for preparing transparent soil based on the 3D printing transparent soil granular material described in Example 1, comprising the following steps:

[0035] 1) Establish a three-dimensional model of transparent soil particles using Fourier transform. Using 3D modeling software, after cross-sections are obtained using Fourier transform in a two-dimensional (2D) state, interpolation is used to generate particles simulating geotechnical materials in 3D space.

[0036] 2) Using the light-curing 3D printer to control the characteristics of the printing form and material properties, print transparent particles that are consistent with natural soil particles, and then obtain properties similar to natural soil. Among them, the printing material of transparent soil particles is selected from photosensitive resin. Photosensitive resin has good transparency, stable properties, high strength and hardness, no pollution and toxicity....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com