Hydrogenated amorphous silicon film preparation method

A technology for the preparation of hydrogenated amorphous silicon and thin films, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problem of insignificant improvement of passivation effect, and achieves the optimization of interface quality, the improvement of minority carrier life, and the improvement of efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The essence of the present invention will be further described below in conjunction with the accompanying drawings and examples, but the content of the present invention is not limited thereto.

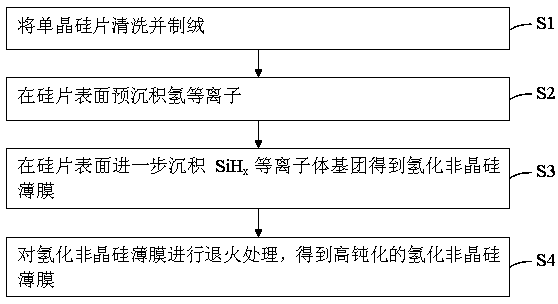

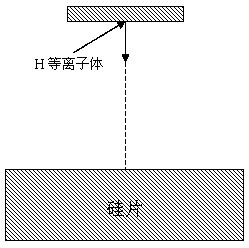

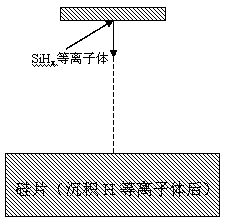

[0025] Such as figure 1 Shown is the hydrogenated amorphous silicon thin film preparation method provided by the present invention. It can be seen from the figure that the preparation method includes: S1 cleaning and texturing the single crystal silicon wafer; S2 pre-depositing hydrogen plasma on the surface of the silicon wafer; S3 further deposits SiH on the surface of the silicon wafer x Plasma group to obtain a hydrogenated amorphous silicon film, where x=1 or 2 or 3; S4 annealing the hydrogenated amorphous silicon film to obtain a highly passivated hydrogenated amorphous silicon film.

[0026] In this preparation method, the cleaned and textured silicon wafer is placed in a PECVD chamber, the incident kinetic energy of H plasma is controlled by PECVD technology, the silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com