A method for preparing a novel W doped slag based binding material with different CeO2 loads

A technology of steel slag-based rubber and loading capacity, which is applied in chemical instruments and methods, hydrogen production, inorganic chemistry, etc., and can solve the problems of high cost of photocatalyst preparation, low quantum yield, and dispersion of photocatalyst powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

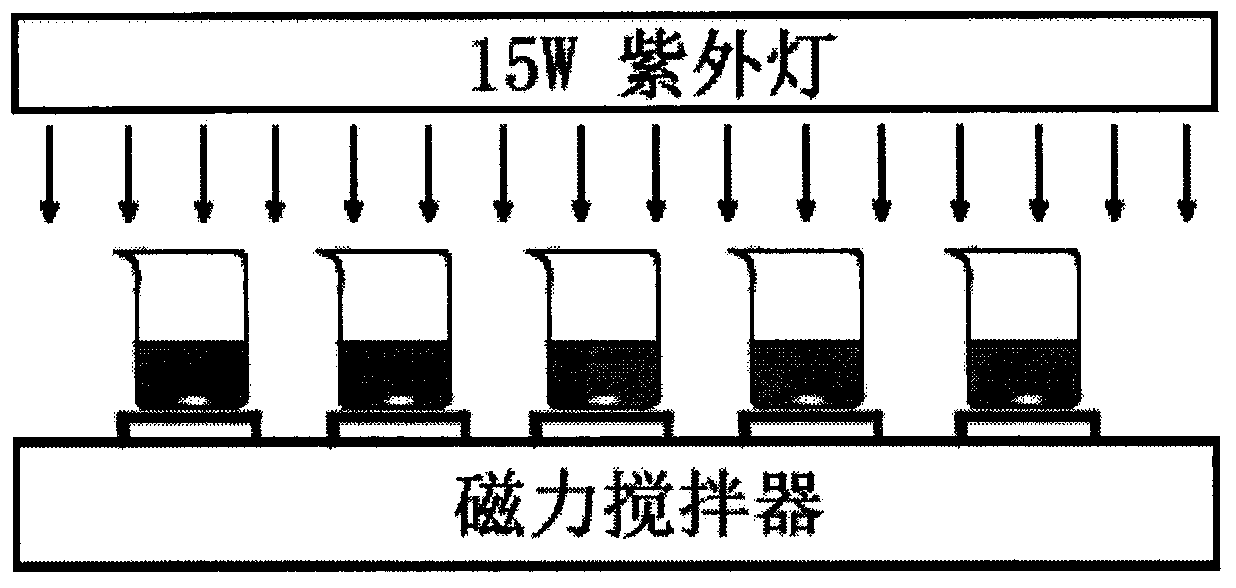

[0032] W-doped CeO 2 Preparation of Supported Alkali Excited Steel Slag-Based Catalyst

[0033] 1. Preparation of alkali-activated steel slag-based cementitious materials

[0034] The steel slag from Hanchenglong Steel was used in this embodiment, which was ground by a ball mill and sieved by a 0.08mm square hole sieve. Density measured by Lee bottle is 3.03g / cm 3 , the specific surface area is 490m by Blaine's specific area meter 2 / kg. The chemical composition of steel slag raw materials is shown in Table 1.

[0035] Table 1 Chemical composition of steel slag raw materials

[0036]

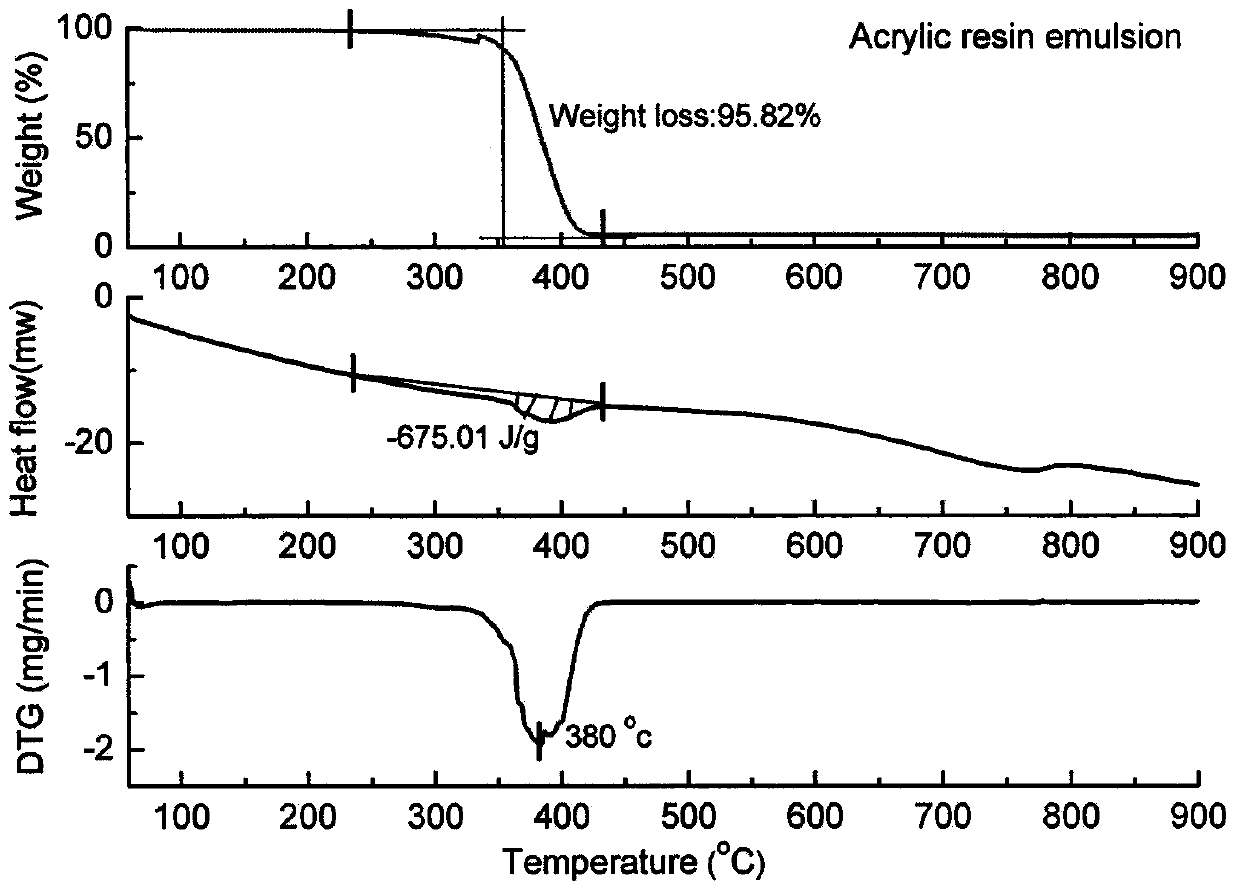

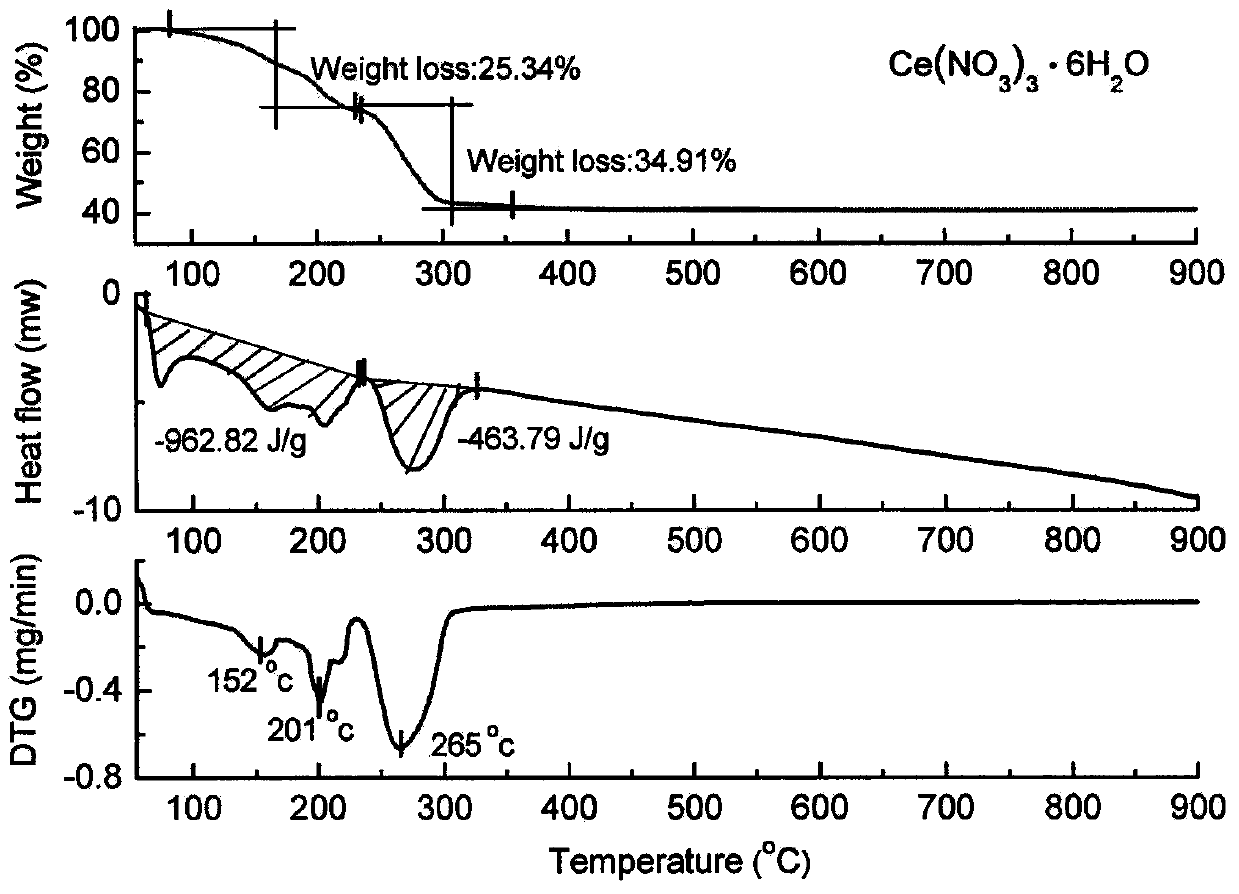

[0037]Dry the silica fume for later use, dry mix the silica fume and steel slag evenly, dissolve 60g NaOH with 100ml water, let the alkali solution stand to cool and add the aqueous solution dispersed with acrylic resin to the SJ-160 plastic sand mixer. Weigh 1500g of the mixture (steel slag and silica fume in a mass ratio of 9:1) and pour it into the mixture for stirring. Stir slowly f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com