Antibacterial high-toughness PA66/PPO composite material and preparation method thereof

A technology of PA66 and composite materials, which is applied in the field of antibacterial and high-toughness PA66/PPO composite materials and its preparation, can solve the problems of no mention of the mechanical properties and antibacterial properties of antibacterial plastics, poor antibacterial performance, and intolerance to non-polar solvents, etc. , to achieve long-lasting excellent antibacterial effect, long-lasting excellent antibacterial properties, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

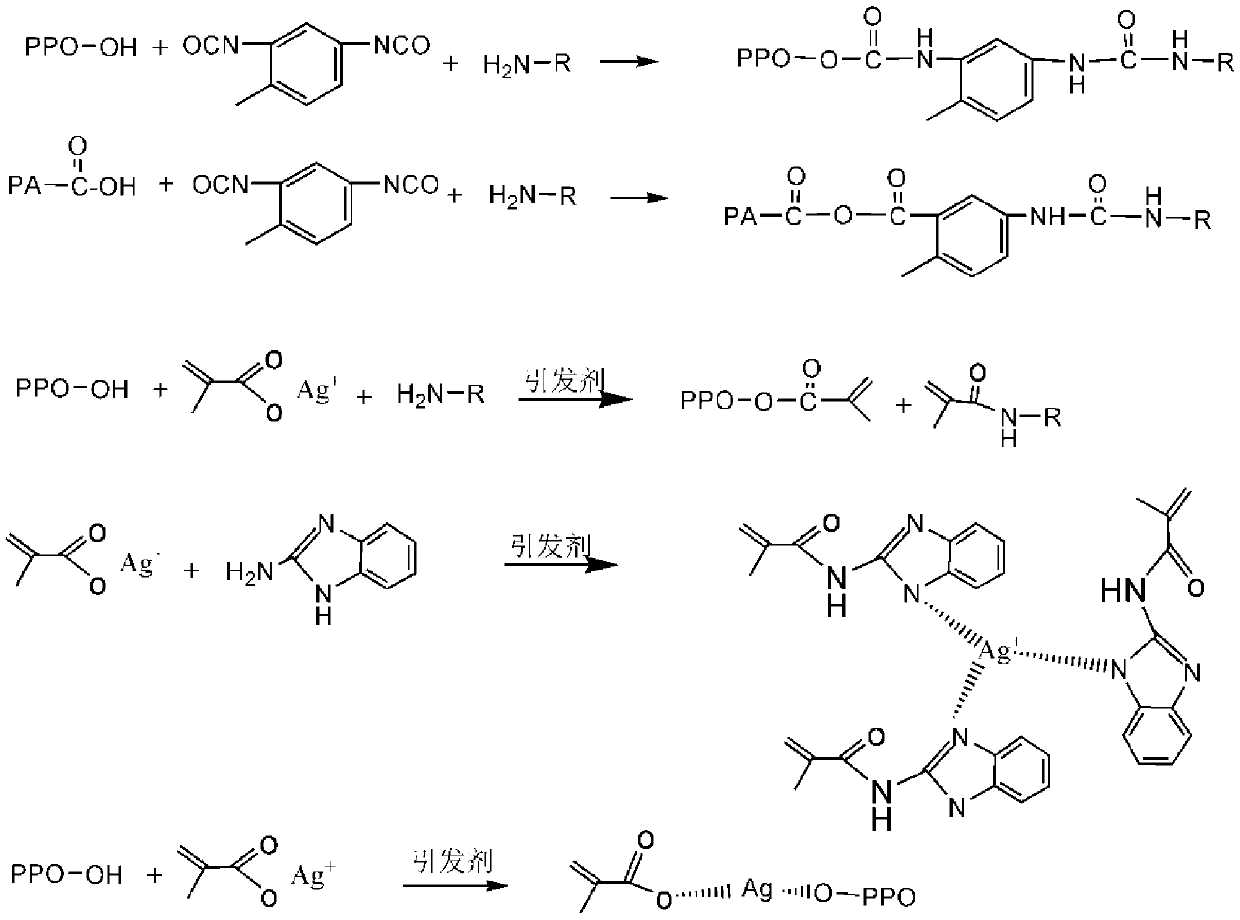

Method used

Image

Examples

Embodiment 1

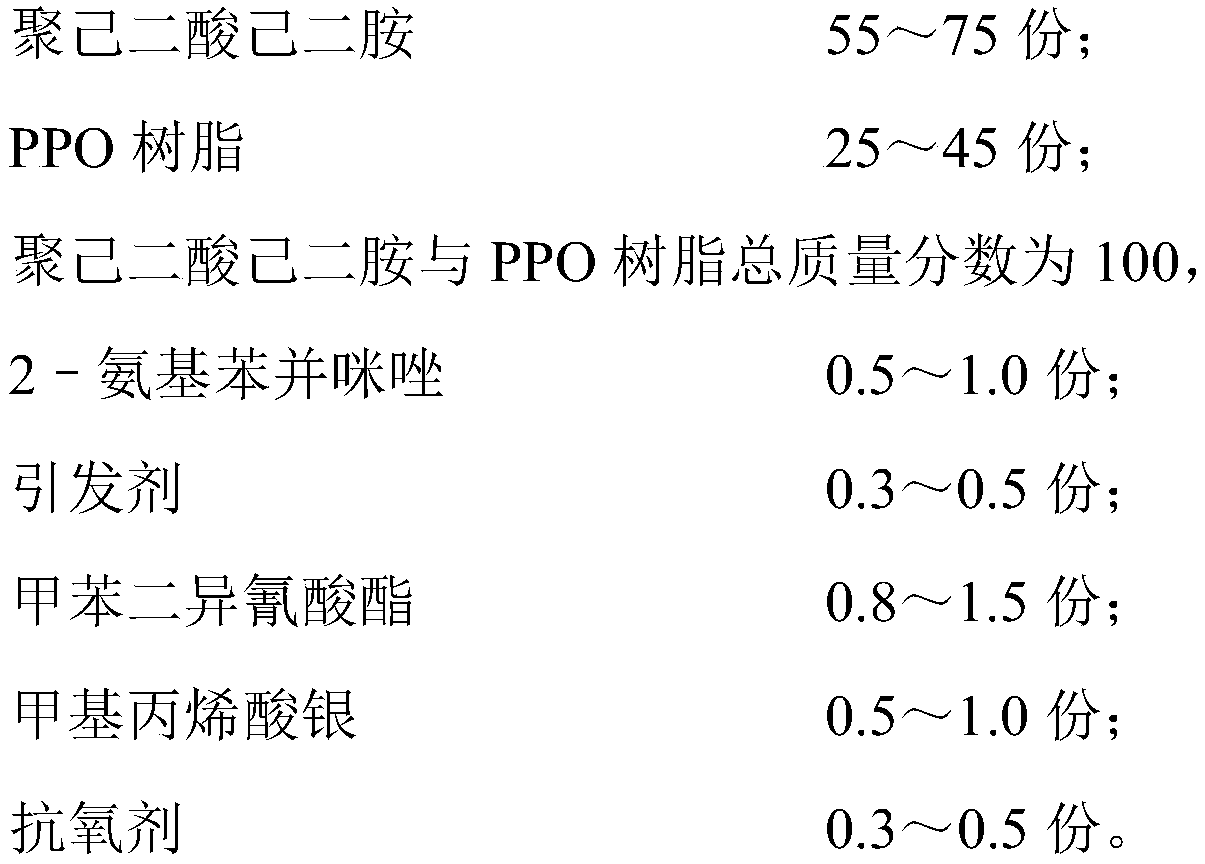

[0040]In this embodiment, a kind of antibacterial and high toughness PA66 / PPO composite material is prepared from the following raw materials in parts by weight:

[0041]

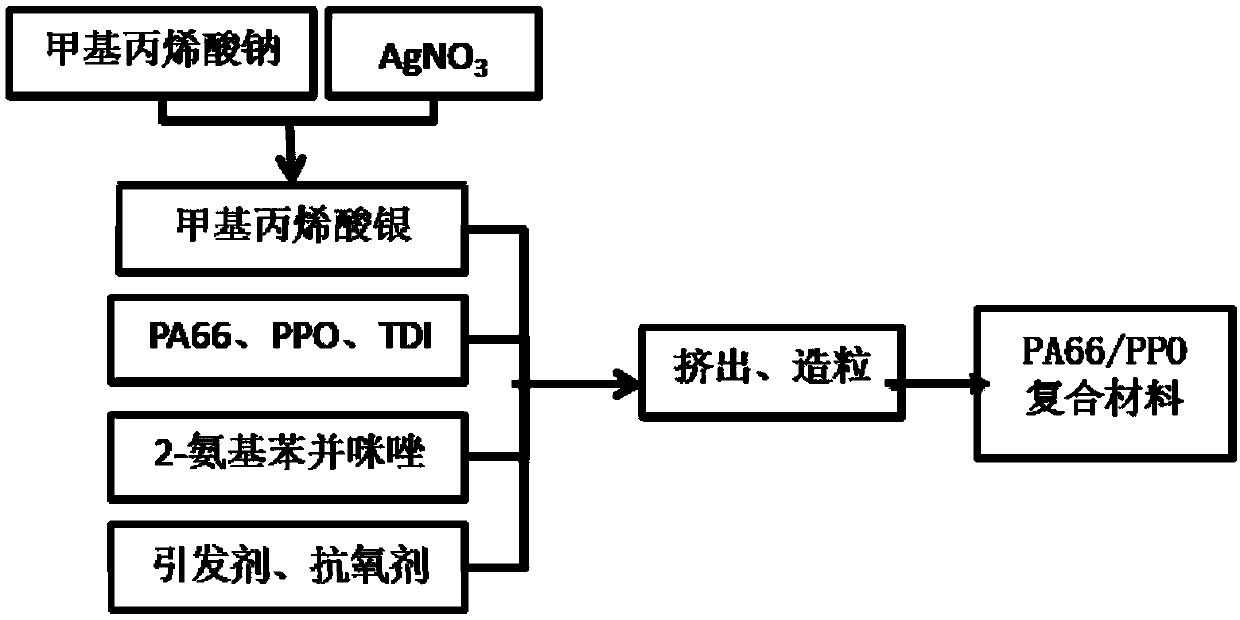

[0042] The preparation method of the above-mentioned antibacterial and high-toughness PA66 / PPO composite material, the specific steps are as follows:

[0043] After the dried polyhexamethylene adipate, polyphenylene ether PPO and 2-aminobenzimidazole, toluene diisocyanate, silver methacrylate, initiator and antioxidant are mixed uniformly according to the mass ratio, the mixture is extruded by twin-screw Exit machine melt extrusion and granulation, the process parameters are as follows: the temperature of the first zone is 230°C, the temperature of the second zone is 250°C, the temperature of the third zone is 250°C, the temperature of the fourth zone is 250°C, the temperature of the fifth zone is 250°C, the temperature of the sixth zone is 250°C, The temperature is 250° C., the die head temperature is 2...

Embodiment 2

[0045] In this embodiment, a kind of antibacterial and high toughness PA66 / PPO composite material is prepared from the following raw materials in parts by weight:

[0046]

[0047]

[0048] The preparation method of the above-mentioned antibacterial and high-toughness PA66 / PPO composite material, the specific steps are as follows:

[0049] After the dried polyhexamethylene adipate, polyphenylene ether PPO and 2-aminobenzimidazole, toluene diisocyanate, silver methacrylate, initiator and antioxidant are mixed uniformly according to the mass ratio, the mixture is extruded by twin-screw Exit machine melt extrusion, granulation, the process parameters are as follows: the temperature of the first zone is 240°C, the temperature of the second zone is 260°C, the temperature of the third zone is 260°C, the temperature of the fourth zone is 260°C, the temperature of the fifth zone is 260°C, the temperature of the sixth zone is 260°C The temperature is 250° C., the die head tempera...

Embodiment 3

[0051] In this embodiment, a kind of antibacterial and high toughness PA66 / PPO composite material is prepared from the following raw materials in parts by weight:

[0052]

[0053] The preparation method of the above-mentioned antibacterial and high-toughness PA66 / PPO composite material, the specific steps are as follows:

[0054] After the dried polyhexamethylene adipate, polyphenylene ether PPO and 2-aminobenzimidazole, toluene diisocyanate, silver methacrylate, initiator and antioxidant are mixed uniformly according to the mass ratio, the mixture is extruded by twin-screw Exit machine melt extrusion and granulation, the process parameters are as follows: the temperature of the first zone is 260°C, the temperature of the second zone is 260°C, the temperature of the third zone is 260°C, the temperature of the fourth zone is 260°C, the temperature of the fifth zone is 270°C, and the temperature of the sixth zone is 270°C. The temperature is 260°C, the die head temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com