Nickel-based alloy, preparation method and article thereof

A technology of nickel-based alloys and articles, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., and can solve the problems of low creep strength at high temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

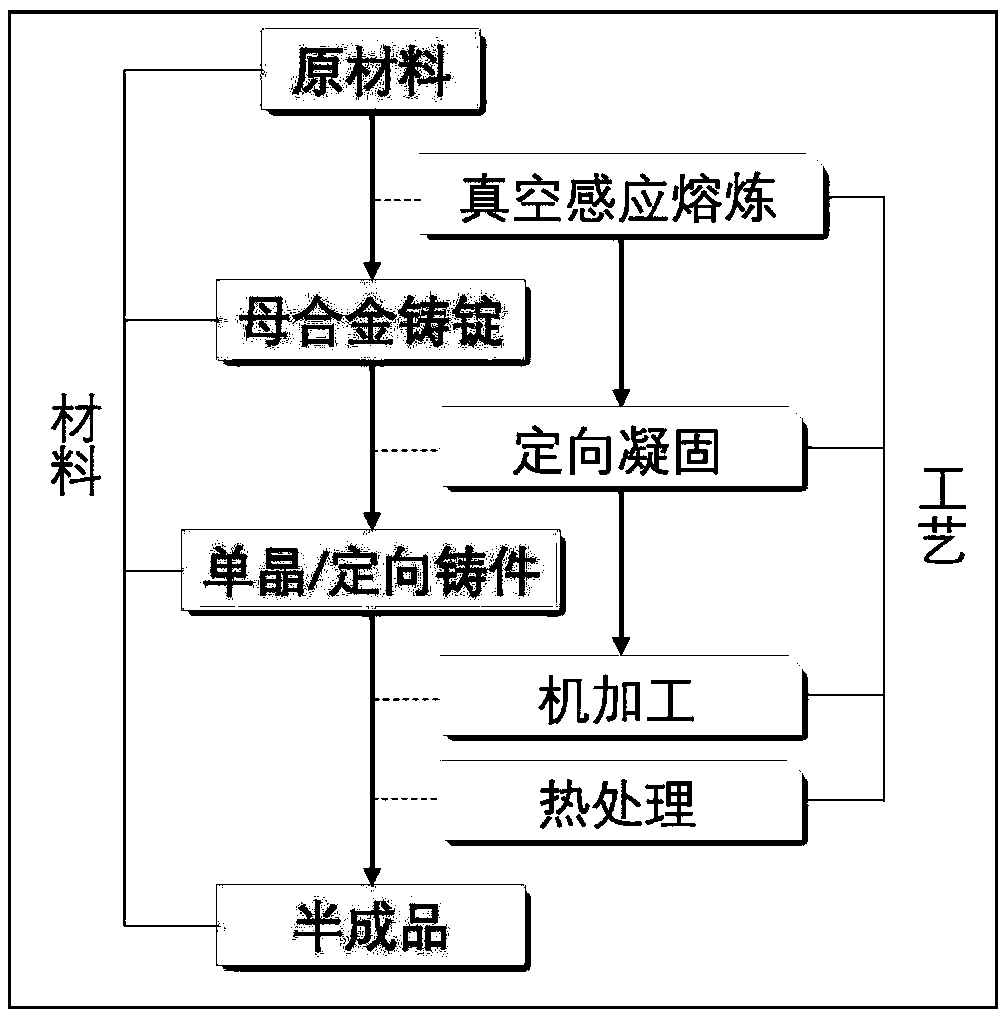

[0079] This application also provides a method for preparing a nickel-based alloy, including the following steps:

[0080] A) Prepare nickel-based master alloy ingots according to the above-mentioned nickel-based alloy composition ratio;

[0081] B) Remelting the nickel-based master alloy ingot, and then preparing nickel-based alloy castings;

[0082] C) The nickel-based alloy casting is heat-treated to obtain a nickel-based alloy.

[0083] In the above-mentioned preparation method of the nickel-based alloy, the specific composition of the nickel-based master alloy ingot has been described in detail above, and will not be repeated here.

[0084] In the above process of preparing the nickel-based alloy, the method for preparing the nickel-based master alloy ingot is performed according to a method well-known to those skilled in the art. For example, in this application, the raw materials are smelted in a vacuum melting furnace according to the composition ratio. To obtain a nickel-based...

Embodiment

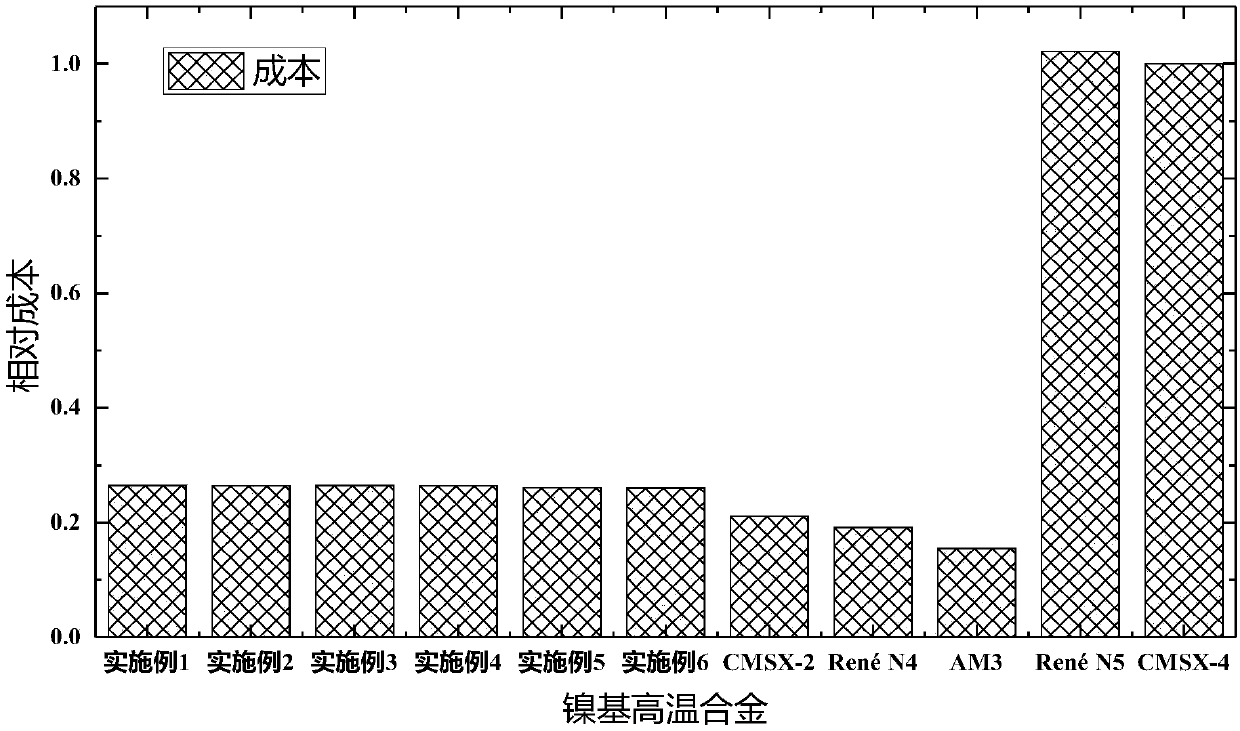

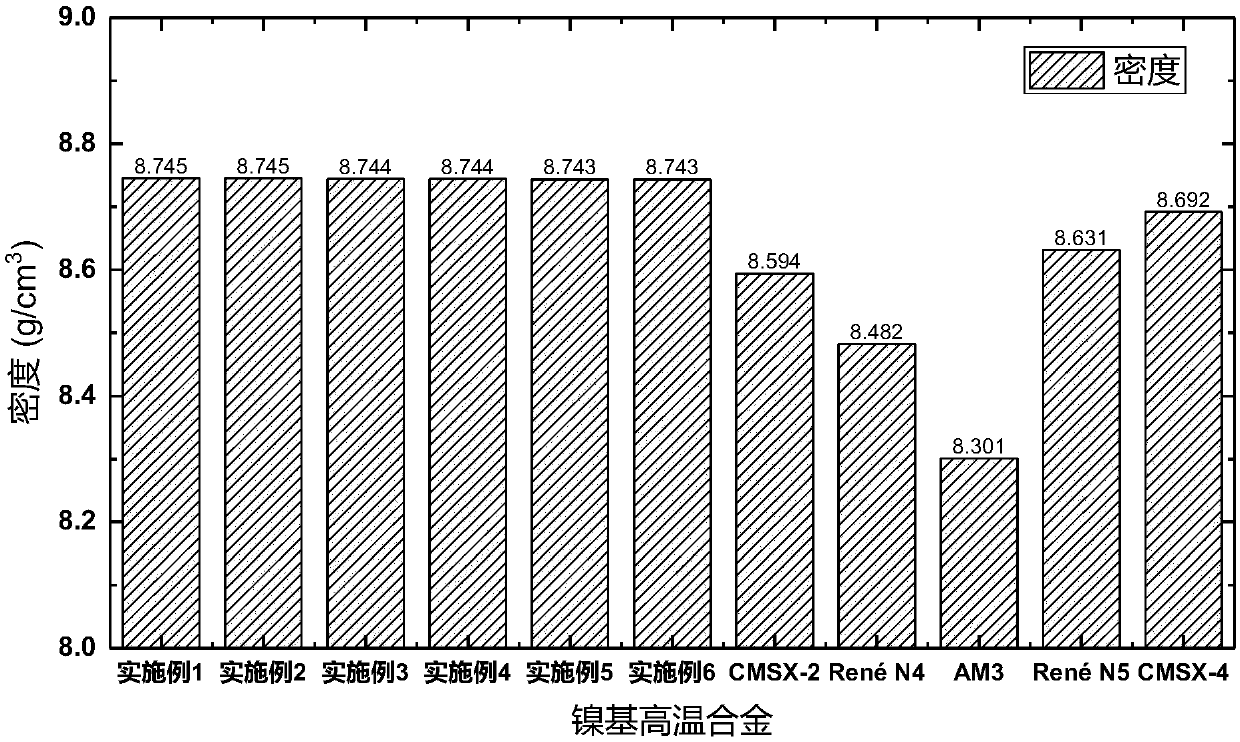

[0098] The nickel-based superalloy of the present application achieves a good balance in alloy density, alloy cost, structural stability, high-temperature strength, etc., and has excellent comprehensive properties. In order to further illustrate the effect of this application, this application lists 7 specific examples, and compares 6 of them with 5 existing alloys. The alloy compositions of the 7 examples and the 5 existing alloy compositions are shown in Table 1. In the examples, the method for preparing the nickel-based superalloy is specifically:

[0099] 1) Put the raw materials with the distribution ratio shown in Table 1 into the vacuum induction melting furnace to smelt the alloy and prepare the master alloy ingot;

[0100] 2) Remelting the master alloy ingot in vacuum equipment, and then prepare columnar crystal castings by directional solidification in a mold shell formed by refractory materials, or prepare single crystal castings by spiral crystal selection or seed cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com