A caramel color online detection device

A detection device, caramel color technology, applied in the direction of color measurement devices, measuring devices, sampling devices, etc., can solve the problems of difficult sampling of caramel color, high viscosity, etc., to achieve the effect of reducing worker operations, reducing impact, and improving product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

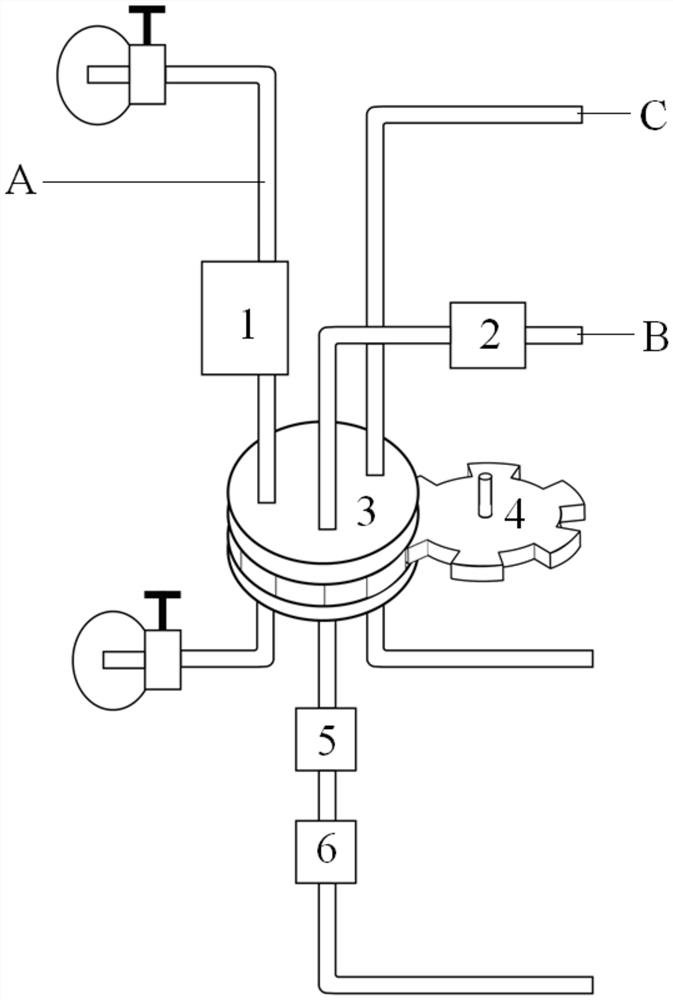

[0033] The method of using the above-mentioned caramel color online detection device:

[0034] Step 1: Carry out the method I caramel color reaction in the reactor, add sugar raw materials and catalysts, and heat the reactor;

[0035] Step 2: Install a caramel-colored on-line monitoring device on the right side of the reactor, and use pump 1 and rubber-plastic sponge material to cover the polyurethane pipeline to form a circulation pipeline;

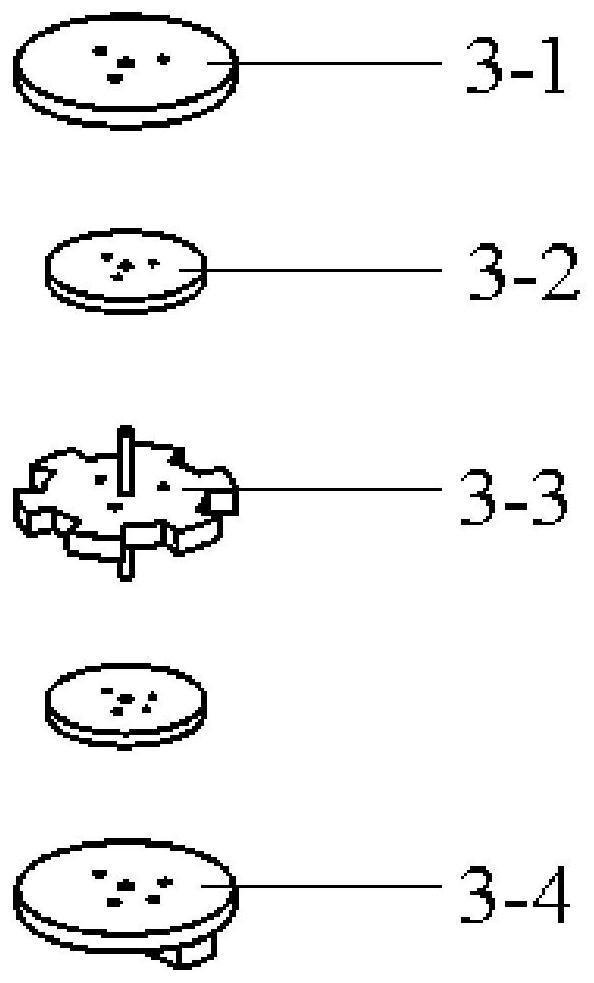

[0036] Step 3: The sampler 3 fixedly samples about 0.1 g, and measures the viscosity of the sample at the same time;

[0037] Step 4: Select the dosing device 2 of the 100mL volume chamber, and the water inflow is a quarter of the chamber, that is, 25.0mL. The water inflow dissolves the caramel color, rinses, and flows into the dissolving device 5;

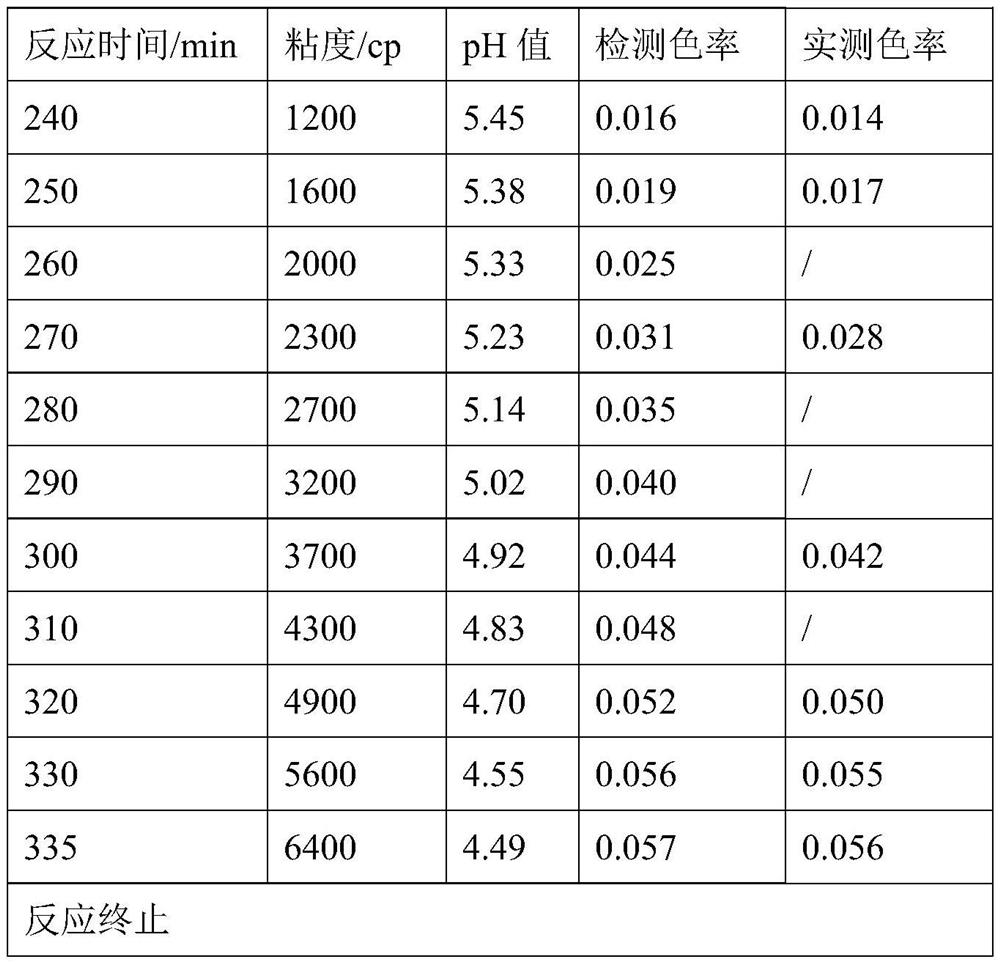

[0038] Step 5: In the dissolving device 5, the caramel-colored sample is thoroughly dissolved after high-frequency oscillation, and the pH value of the sample is measured at the same time; ...

Embodiment 2

[0045] The method of using the above-mentioned caramel color online detection device:

[0046] Step 1: Carry out the method III caramel color reaction in the reaction kettle, add sugar raw materials and catalysts, and heat the reaction kettle;

[0047] Step 2: Install a caramel-colored on-line monitoring device on the right side of the reactor, and use pump 1 and rubber-plastic sponge material to cover the polyurethane pipeline to form a circulation pipeline;

[0048] Step 3: Sampler 3 fixedly samples about 0.1g;

[0049] Step 4: Select the dosing device 2 of the 100mL volume chamber, and the water inflow is 1 / 2 of the chamber, that is, 50.0mL. The water inflow dissolves the caramel color, washes it, and flows into the dissolving device 5;

[0050] Step 5: measure the pH of the sample in the dissolving device 5;

[0051] Step 6: Continue to add the remaining 50.0mL of water and mix well, then flow the dissolved sample into the detection device 6, and detect the color ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com