Sensitive microrna optical fiber sensing device and its production and measurement method

A technology of optical fiber sensing and fabrication method, applied in the field of biomedical optical sensing technology design, can solve problems such as insufficient sensitivity, achieve low detection limit, high sensitivity, and enhance the effect of evanescent field energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Optical fiber sensing technology uses light waves as the information carrier, and has the advantages of low cost, compact structure, high sensitivity, remote monitoring, corrosion resistance, and strong biocompatibility. It has become one of the most rapidly developing biosensing technologies in recent years. In the relevant reports of fiber optic biosensing research, high performance fiber optic interferometer has become a research hotspot. The most representative one is the tapered micro-nano optical fiber interferometer sensor developed in recent years. In addition to the characteristics of conventional optical fiber sensors, this type of optical fiber sensor can also use the evanescent wave mode excited by it that is sensitive to the surrounding environment , not only greatly enriched its detection objects, but also improved the measurement accuracy. Moreover, the manufacturing cost is low, meets the use requirements of disposable clinical medical devices, and has v...

Embodiment 2

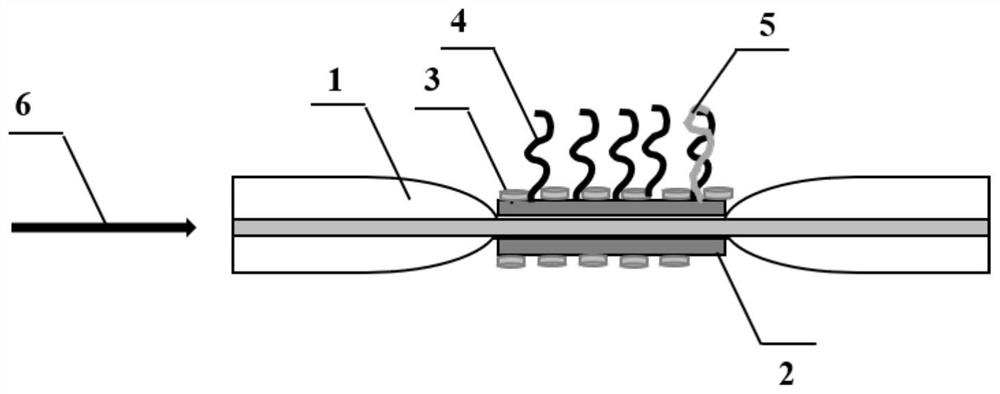

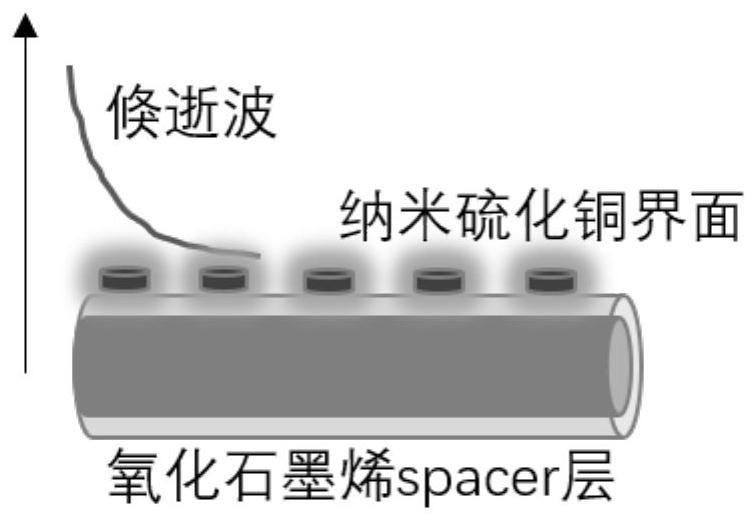

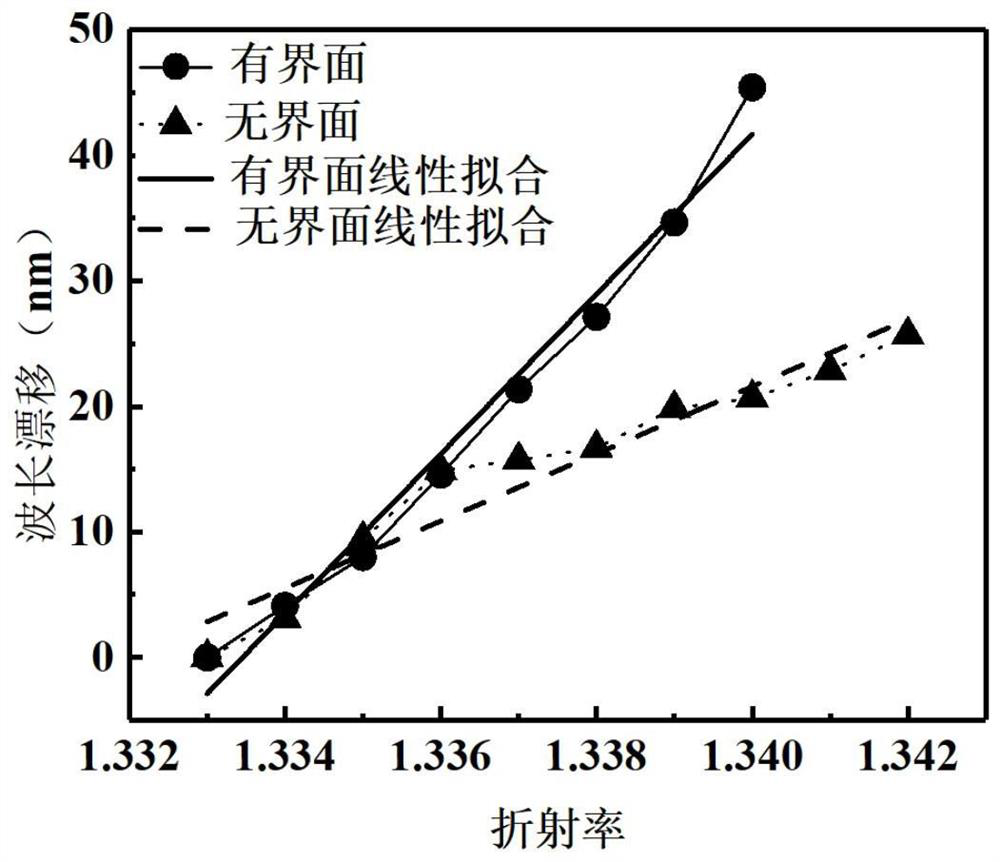

[0055] Such as figure 1 As shown, this embodiment provides a method for detecting small molecule microRNA with enhanced sensitivity to optical fiber sensors, the method comprising: drawing a photosensitive optical fiber on a flame into a tapered micro-nano optical fiber interferometer 1 with a diameter of 6.5 microns , the tapered micro-nano fiber interferometer 1 is fused with a single-mode fiber to make a fiber sensor; the graphene oxide spacer layer 2 is assembled into a single-layer film on the side of the tapered micro-nano fiber interferometer 1, and the plasmon resonance Nano-copper sulfide particles with peaks in the 1500-1600nm region are assembled on the spacer layer to form an interface layer; the single-stranded DNA probe 4 is fixed on the surface of the interface layer through covalent bonding; after the single-stranded DNA probe 4 is fixed, the The optical fiber sensor is immersed in the solution containing microRNA, and the light source 6 is input into the taper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com