Three-dimensional composite material of titanium carbide, and preparation method thereof, and application in constructing thrombin aptasensor

An aptamer sensor and composite material technology, applied in the analysis of materials, material analysis through electromagnetic means, instruments, etc., can solve the problems of cumbersome and complicated processes, achieve accelerated electron transfer rate, good electrochemical performance, and improve charge separation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

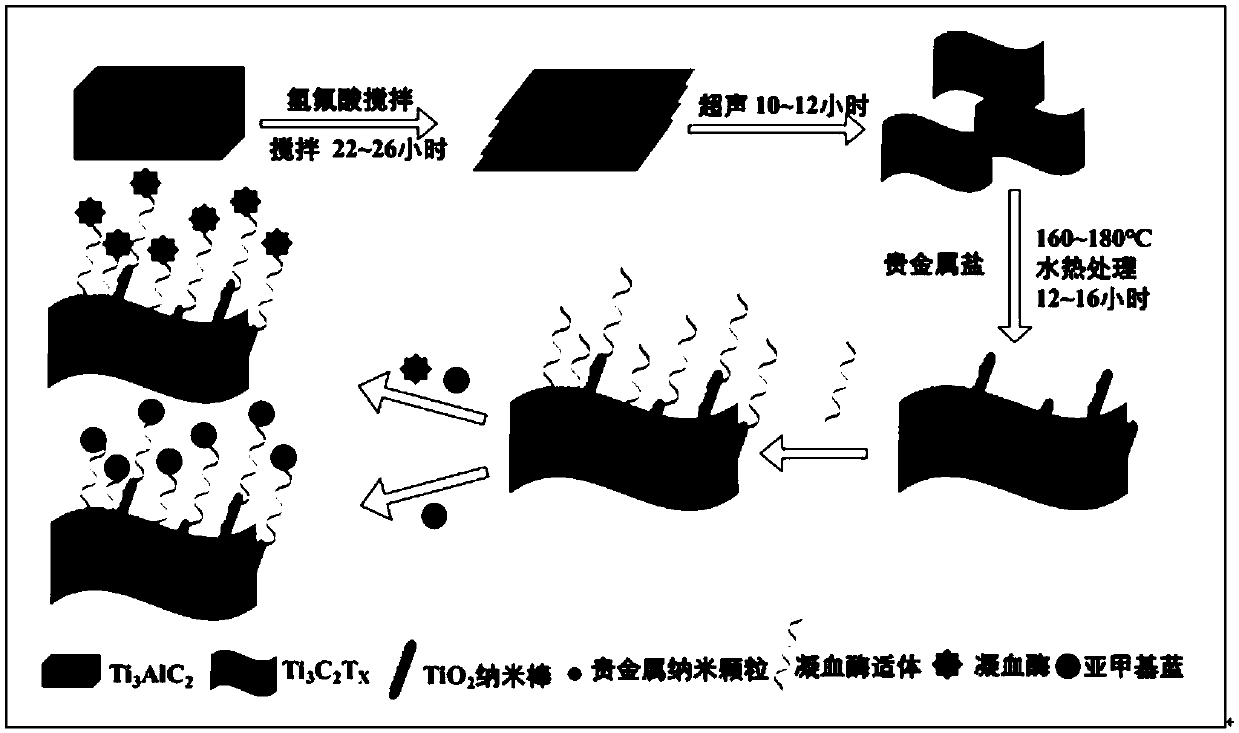

[0034] In a first exemplary embodiment of the present disclosure, a M NPs / TiO 2 / Ti 3 C 2 T X A method for preparing a composite material, the method comprising:

[0035] layered Ti 3 C 2 T X , noble metal salt and water are mixed evenly, then hydrothermally reacted at 160-200°C for 12-16 hours, cooled and left to stand for 12-15 hours to prepare M NPs / TiO 2 / Ti 3 C 2 T X composite material.

[0036] The present disclosure adopts a one-pot hydrothermal method to directly reduce noble metal nanoparticles (M NPs) to the composite material TiO 2 / Ti 3 C 2 T X At the same time, after the end of the hydrothermal reaction, the TiO 2 Growth of nanorods to obtain TiO 2 It is a nanorod structure and its size is relatively large. The inventor unexpectedly found that this structure is more conducive to stretching Ti 3 C 2 T X The layered structure is conducive to improving the proton transmission rate, which is more conducive to the detection of thrombin.

[0037] Afte...

Embodiment 1

[0069] MXenes-Ti 3 C 2 T X Synthesis

[0070] 3g Ti 3 AlC 2 Slowly add 30 mL of 9M HF solution at 5°C to obtain a mixed solution. The mixed solution was stirred at 5 °C for 20 min and then at 45 °C for 24 h to obtain Ti 3 C 2 T X suspension of flakes. It was then centrifuged until the pH of the suspension reached 6.5, layered Ti was obtained by sonication for 11 h 3 C 2 T X The colloidal solution was then centrifuged at 3500 rpm for 35 minutes to remove the precipitate.

[0071] TiO 2 / Ti 3 C 2 T X Synthesis of Hydrogels

[0072] 20mL (4mg / mL) Ti 3 C 2 T X The solution was dispersed in 5 mL of water and sonicated for 1.2 h to obtain a homogeneous suspension. Then, the suspension was transferred into a Teflon sealed autoclave and heated at 180 °C for 14 h. After cooling to room temperature, let it stand for 14 hours to form TiO 2 Growth of nanorods. Synthesized three-dimensional composite nanomaterial TiO 2 / Ti 3 C 2 T X Wash with water, then store in...

Embodiment 2

[0090] MXenes-Ti 3 C 2 T X Synthesis

[0091] 3g Ti 3 AlC 2 Slowly add 30 mL of 9M HF solution at 5°C to obtain a mixed solution. The mixed solution was stirred at 5 °C for 20 min and then at 45 °C for 24 h to obtain Ti 3 C 2 T X suspension of flakes. It was then centrifuged until the pH of the suspension reached 6.5, layered Ti was obtained by sonication for 11 h 3 C 2 T X The colloidal solution was then centrifuged at 3500 rpm for 35 minutes to remove the precipitate.

[0092] TiO 2 / Ti 3 C 2 T X Synthesis of Hydrogels

[0093] 20mL (4mg / mL) of Ti3 C 2 T X The solution was dispersed in 5 mL of water and sonicated for 1.2 h to obtain a homogeneous suspension. Then, the suspension was transferred into a Teflon sealed autoclave and heated at 180 °C for 14 h. After cooling to room temperature, let it stand for 14 hours to form TiO 2 Growth of nanorods. Synthesized three-dimensional composite nanomaterial TiO 2 / Ti 3 C 2 T X Wash with water, then store i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com