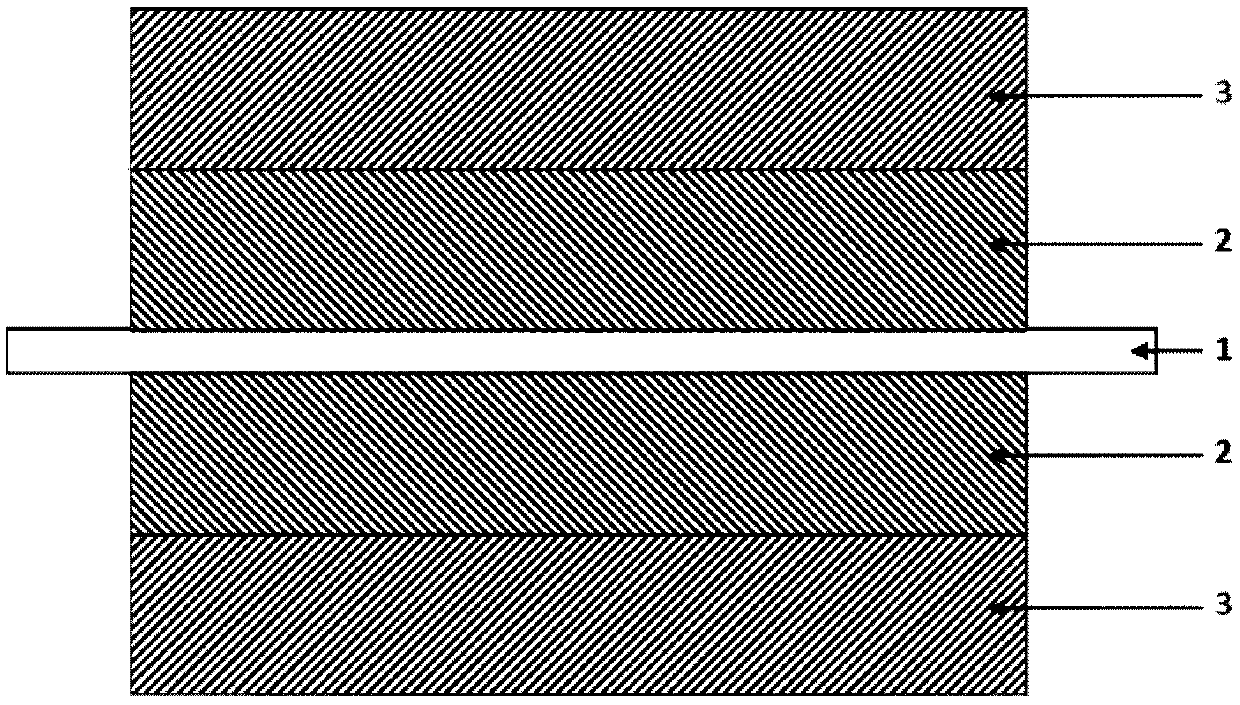

Dual-layer structure positive electrode plate and fabrication method and application thereof

A technology of positive electrode sheet and double-layer structure, which is applied in the direction of electrode manufacturing, structural parts, electrode rolling/calendering, etc., can solve the problems of poor electrolyte wettability, unsatisfactory, poor electrical conductivity, etc., and achieve good electrochemical performance, Good compatibility and the effect of improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

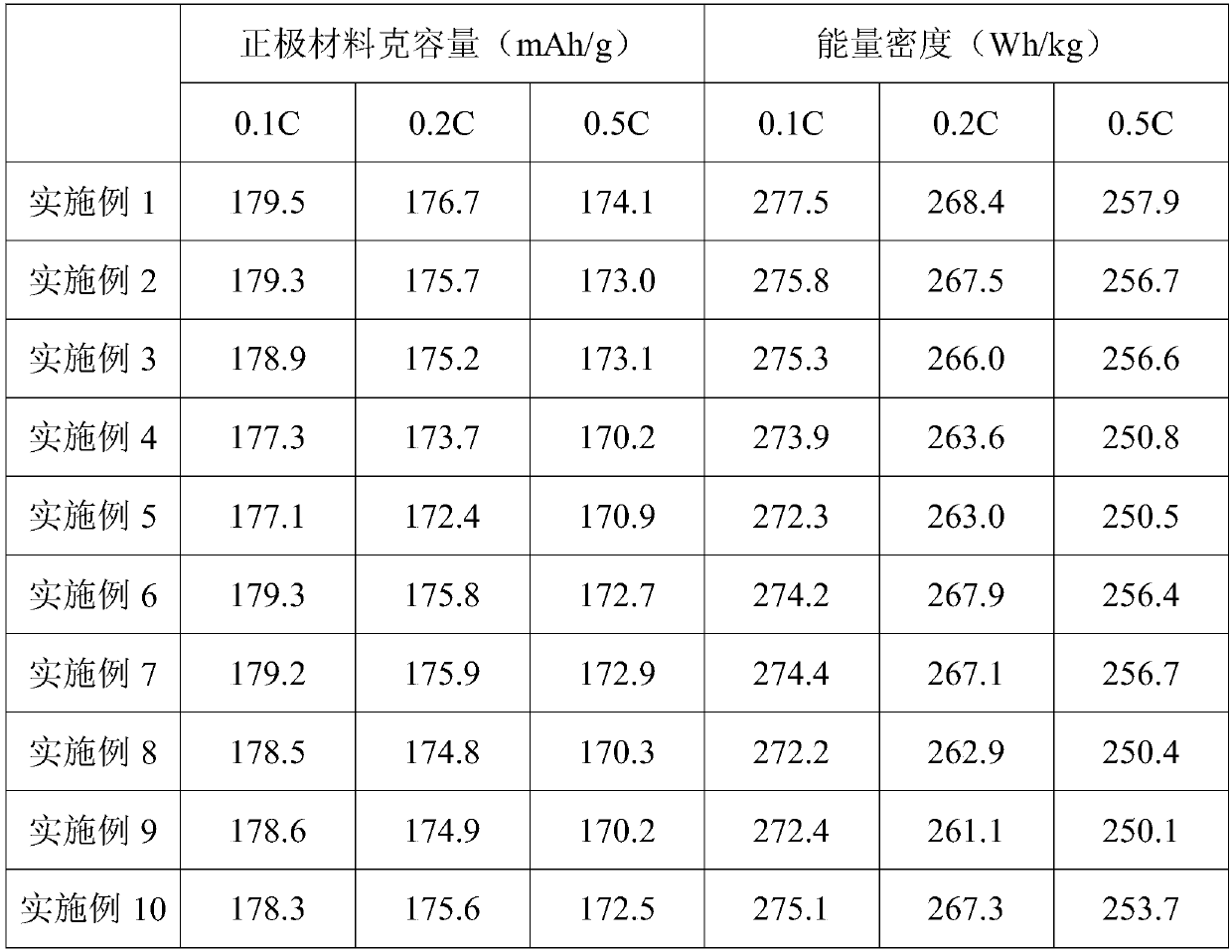

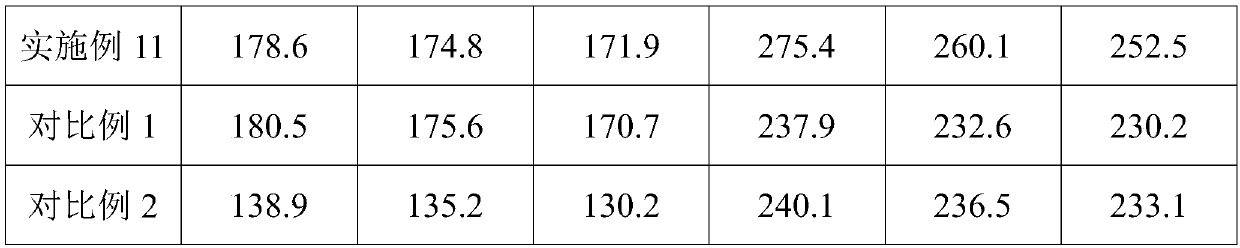

Examples

Embodiment 1

[0064] A method for preparing a double-layer structure positive pole piece comprises the steps of:

[0065] (1) Mix nickel-cobalt lithium aluminate, carbon black, and polyvinylidene fluoride in a mass ratio of 97:1:2 to prepare a mixture, and then mix the mixture with N-methylpyrrolidone in a mass ratio of 3:1, Prepare electrode slurry;

[0066] (2) Coating the electrode slurry on both sides of the current collector with an area density of 30 mg / cm 2 The first coating layer, the first coating layer is rolled once, the thickness of the first coating layer is 83 μm, and then the electrode slurry is coated on the first coating layer after rolling with an area density of 30mg / cm 2 The second coating layer is finally rolled twice, the second coating thickness is 102 μm, and the porosity of the first electrode material layer is 18.0%, and the porosity of the second electrode material layer is 33.0%. Structural positive pole piece.

Embodiment 2

[0068] The difference with Example 1 is that the areal density of the first coating layer in step (2) is 30mg / cm 2 , the thickness of the first coating layer is 80 μm, and the porosity of the first electrode material layer in the double-layer structure positive electrode sheet is 15%.

Embodiment 3

[0070] The difference with Example 1 is that the areal density of the first coating layer in step (2) is 30mg / cm 2 , the thickness of the first coating layer is 87 μm, and the porosity of the first electrode material layer in the double-layer structure positive electrode sheet is 22%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com