Semisolid coarse cereal compound beverage for women and processing method

A semi-solid, miscellaneous grain technology, applied in the functions of food ingredients, food ingredients containing natural extracts, applications, etc., can solve the problems of inapplicability to specific groups of people, palatability, poor food continuity, and low solid content, etc. Improve the effect of special needs, good continuous feeding, and high product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

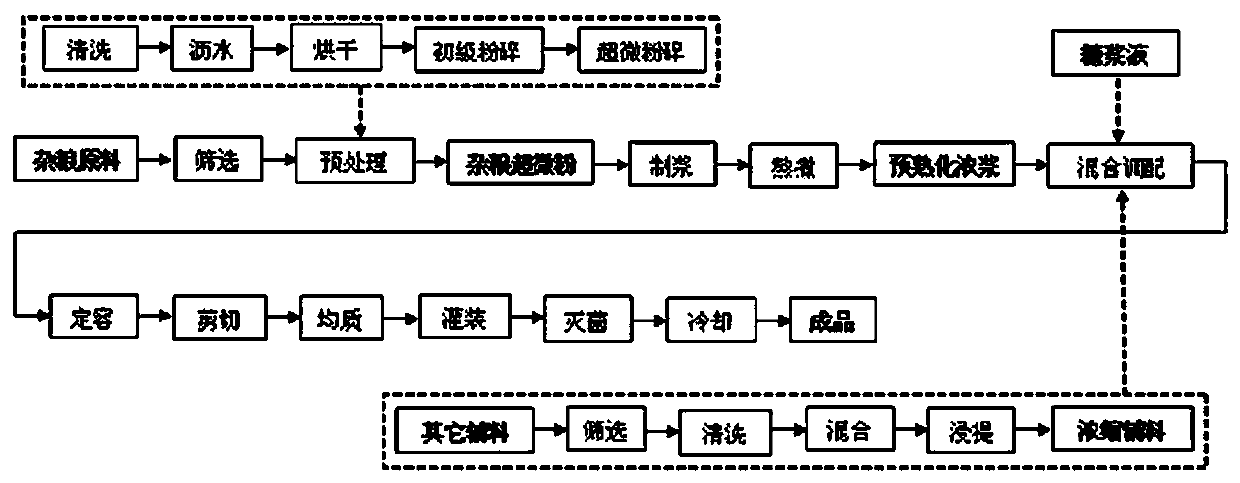

Image

Examples

Embodiment 1

[0038] 1. Preparation of precooked miscellaneous grain slurry

[0039] 1. Raw material screening

[0040] Select high-quality red beans, coix seed rice, and red rice miscellaneous grains to remove gravel, soil clods, foreign grains, insect-eaten grains, imperfect grains, damaged grains, and spot disease grains;

[0041] 2. Pretreatment

[0042] ① cleaning

[0043] First wash the miscellaneous grain raw materials with tap water 2 to 3 times, and then rinse with pure water once to remove the dust on the surface of the miscellaneous grains;

[0044] ② Drain

[0045] Drain off the excess water from the grains after washing;

[0046] ③Drying

[0047] Put the drained miscellaneous grain raw materials into the material tray and use the hot air drying method for drying. The hot air drying temperature is 105°C, the thickness of the tray is 1cm, and the drying time is 20min;

[0048] ④Primary crushing

[0049] The dried miscellaneous grain raw material is subjected to primary cr...

Embodiment 2

[0083] 1. Preparation of precooked miscellaneous grain slurry

[0084] 1. Raw material screening

[0085] Select high-quality red beans, coix seed rice, and red rice miscellaneous grains to remove gravel, soil clods, foreign grains, insect-eaten grains, imperfect grains, damaged grains, and spot disease grains;

[0086] 2. Pretreatment

[0087] ① cleaning

[0088] First wash the miscellaneous grain raw materials with tap water 2 to 3 times, and then rinse with pure water once to remove the dust on the surface of the miscellaneous grains;

[0089] ② Drain

[0090] Drain off the excess water from the grains after washing;

[0091] ③Drying

[0092] Put the drained miscellaneous grain raw materials into the material tray and use the hot air drying method for drying. The hot air drying temperature is 105°C, the thickness of the tray is 2cm, and the drying time is 40min;

[0093] ④Primary crushing

[0094] The dried miscellaneous grain raw material is subjected to primary cr...

Embodiment 3

[0128] 1. Preparation of precooked miscellaneous grain slurry

[0129] 1. Raw material screening

[0130] Select high-quality red beans, coix seed rice, and red rice miscellaneous grains to remove gravel, soil clods, foreign grains, insect-eaten grains, imperfect grains, damaged grains, and spot disease grains;

[0131] 2. Pretreatment

[0132] ① cleaning

[0133] First wash the miscellaneous grain raw materials with tap water 2 to 3 times, and then rinse with pure water once to remove the dust on the surface of the miscellaneous grains;

[0134] ② Drain

[0135] Drain off the excess water from the grains after washing;

[0136] ③Drying

[0137] Put the drained miscellaneous grain raw materials into the material tray and use the hot air drying method for drying. The hot air drying temperature is 105°C, the thickness of the tray is 3cm, and the drying time is 55min;

[0138] ④Primary crushing

[0139] The dried miscellaneous grain raw material is subjected to primary cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com