Modified Pd/BaCe catalyst and preparation method thereof

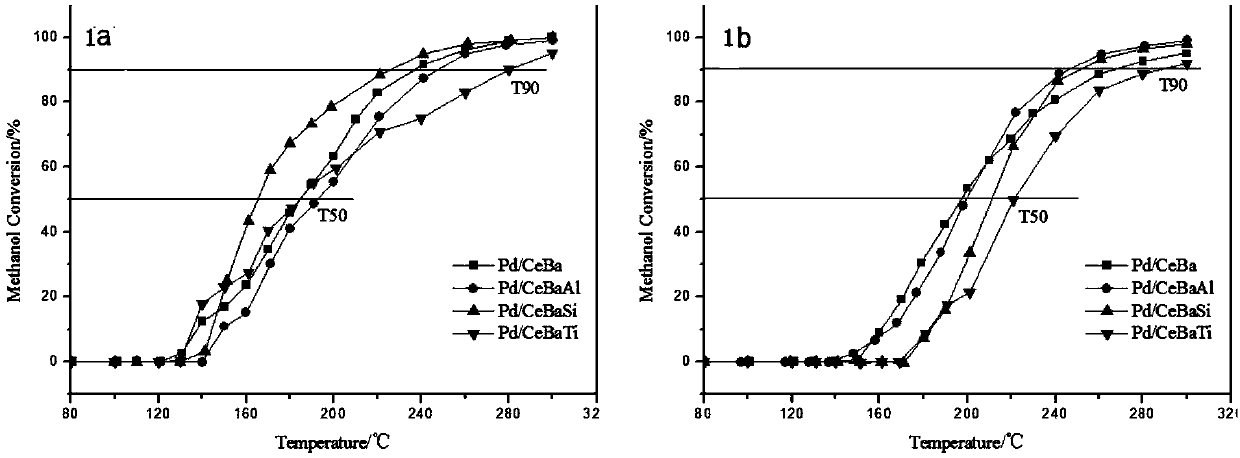

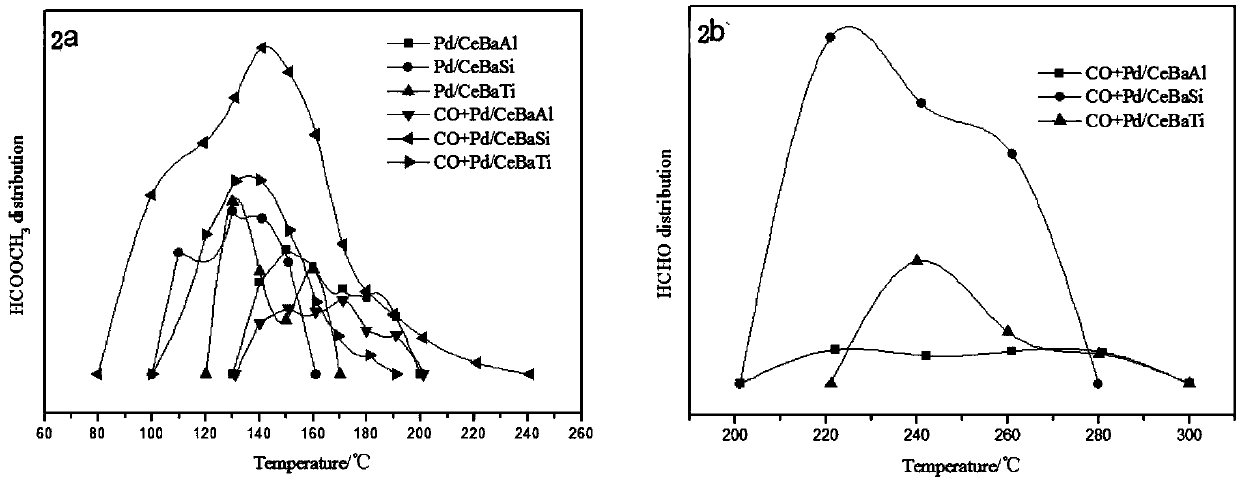

A catalyst and modification technology, which is applied in the field of modified Pd/BaCe catalyst and its preparation, can solve the problems of low heat capacity, reduced catalytic power, and poor purification effect of intermediate products, so as to improve performance, save cost, and reduce light-off and the effect of complete conversion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of the modified Pd / BaCe catalyst of the present embodiment is as follows:

[0032] The preparation of composite oxide, according to the molar ratio of Ba and Ce 0.2:0.8, weigh Ce(NO 3 ) 3 ·6H 2 O, Ba(NO 3 ) 2 Add water, stir until completely dissolved, then drop in the precipitant NH 3 ·H 2 O adjusted the pH to 9.3, aged for 24 hours, then filtered and dried, and the obtained powder was calcined at 550-650°C for 3 hours to obtain a composite oxide.

[0033] Preparation of the carrier, weigh the composite oxide and Al 2 o 3 Grind in a grinder for 35 minutes, and then bake at 550-650° C. for 3 hours to obtain a carrier.

[0034] Catalyst preparation, adding support to PdCl 2 In the aqueous solution, stir and disperse for 0.5h, then dry and bake at 550-650°C for 3h to obtain the catalyst Pd / CeBaAl.

Embodiment 2

[0036] The preparation method of the catalyst of this implementation is the same as that of Example 1, except that the oxide used in this example is SiO 2 . The final prepared catalyst is Pd / CeBaSi.

Embodiment 3

[0038] The preparation method of the catalyst of this implementation is the same as that of Example 1, except that the oxide used in this example is TiO 2 . The final prepared catalyst is Pd / CeBaTi.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com