Preparation method of BiOBr/black phosphorus alkene hetero-junction nano composite material

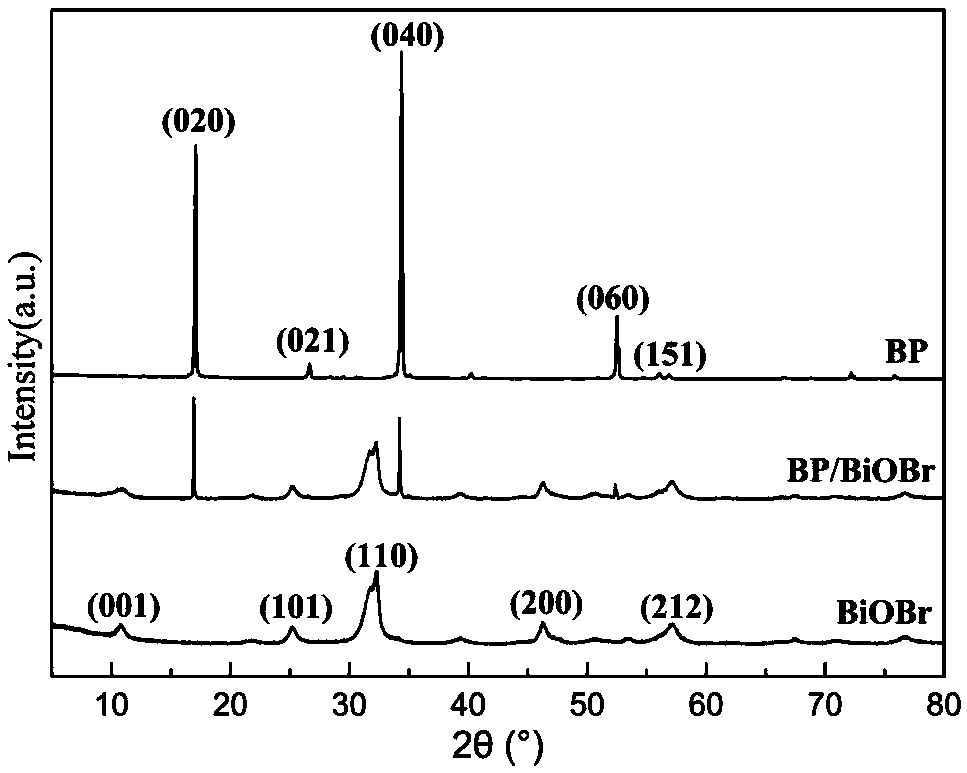

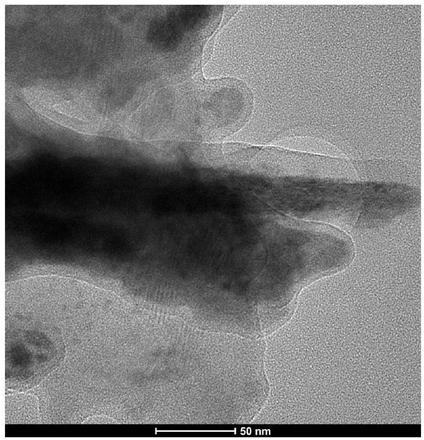

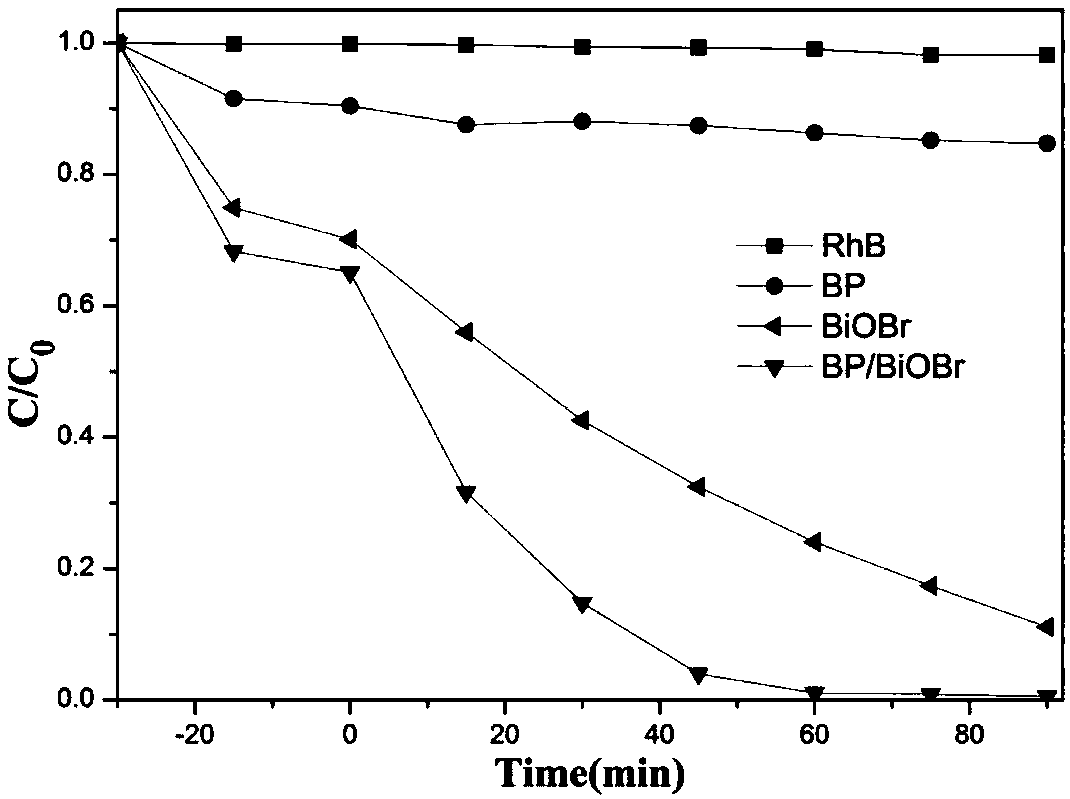

A nano-composite material, black phosphorene technology, applied in the field of environmental pollution control, can solve the problems of poor chemical stability and easy oxidation reaction, achieve high redox ability, high photogenerated electron-hole separation ability, and improve interface phase capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a BiOBr / black phosphorene heterojunction nanocomposite material.

[0028] (1) With 2.91g of Bi(NO 3 ) 3 ·5H 2 O and 0.714g of KBr as raw materials were dissolved in 35mL of ethylene glycol solvent, and the KBr solution was added dropwise to Bi(NO 3 ) 3 solution and magnetically stirred for 1 h; put the mixed solution into a hydrothermal kettle, and dilute to 80% with ethylene glycol, then use solvent heat to react at 120°C for 8 h; cool to room temperature after the reaction, and wash with absolute ethanol 3 times and dried in an oven at 60°C for 12h to prepare flower-like BiOBr;

[0029] (2) Using black phosphorus block as raw material and NMP as solvent, black phosphorene was prepared by ultrasonic stripping combined with vacuum drying under the protection of atmosphere. Take 0.08g of ground black phosphorus tablets and put them into an Erlenmeyer flask filled with argon, add 20ml of NMP into the Erlenmeyer flask, seal the mouth, and ultras...

Embodiment 2

[0032] A method for preparing a BiOBr / black phosphorene heterojunction nanocomposite material.

[0033] (1) With 4.16g of Bi(NO 3 ) 3 ·5H 2 O and 1.428g of KBr were used as raw materials, respectively dissolved in 50mL of ethylene glycol solvent, and the KBr solution was added dropwise to Bi(NO 3 ) 3 solution and magnetically stirred for 1.5h; put the mixed solution into a hydrothermal kettle, and dilute to 80% with ethylene glycol, then use solvent heat to react at 120°C for 9h; Washing 3 times and drying in an oven at 60°C for 14 hours to prepare flower-like BiOBr;

[0034] (2) Using black phosphorus block as raw material and NMP as solvent, black phosphorene was prepared by ultrasonic stripping combined with vacuum drying under the protection of atmosphere. Take 0.12g of ground black phosphorus tablets and put them into an Erlenmeyer flask filled with argon, add 30ml of NMP into the Erlenmeyer flask, seal the mouth, and ultrasonicate at 10°C for 15h; put the ultrasonic...

Embodiment 3

[0037] A method for preparing a BiOBr / black phosphorene heterojunction nanocomposite material.

[0038] (1) With 5.82g of Bi(NO 3 ) 3 ·5H 2 O and 1.02g of KBr were used as raw materials, respectively dissolved in 70mL of ethylene glycol solvent, and the KBr solution was added dropwise to Bi(NO 3 ) 3 solution and magnetically stirred for 2h; put the mixed solution into a hydrothermal kettle, and dilute to 80% with ethylene glycol, and then use solvent heat to react at 120°C for 10h; cool to room temperature after the reaction, and wash with absolute ethanol 3 times and dried in an oven at 60°C for 18 hours to prepare flower-like BiOBr;

[0039](2) Using black phosphorous block as raw material and NMP as solvent, black phosphorene was prepared by using atmosphere-protected ultrasonic stripping combined with vacuum drying. Take 0.16g of ground black phosphorus tablets and put them into an Erlenmeyer flask filled with argon, add 40ml of NMP into the Erlenmeyer flask, seal the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com