A kind of pesticide storage container and preparation method thereof

A technology for storing containers and pesticides, applied to chemical instruments and methods, containers, rigid containers, etc., can solve problems such as poor toughness, high breakage rate, accidental poisoning, etc., and achieve improved elastic modulus, tensile properties, and notched impact strength The effect of strengthening and improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

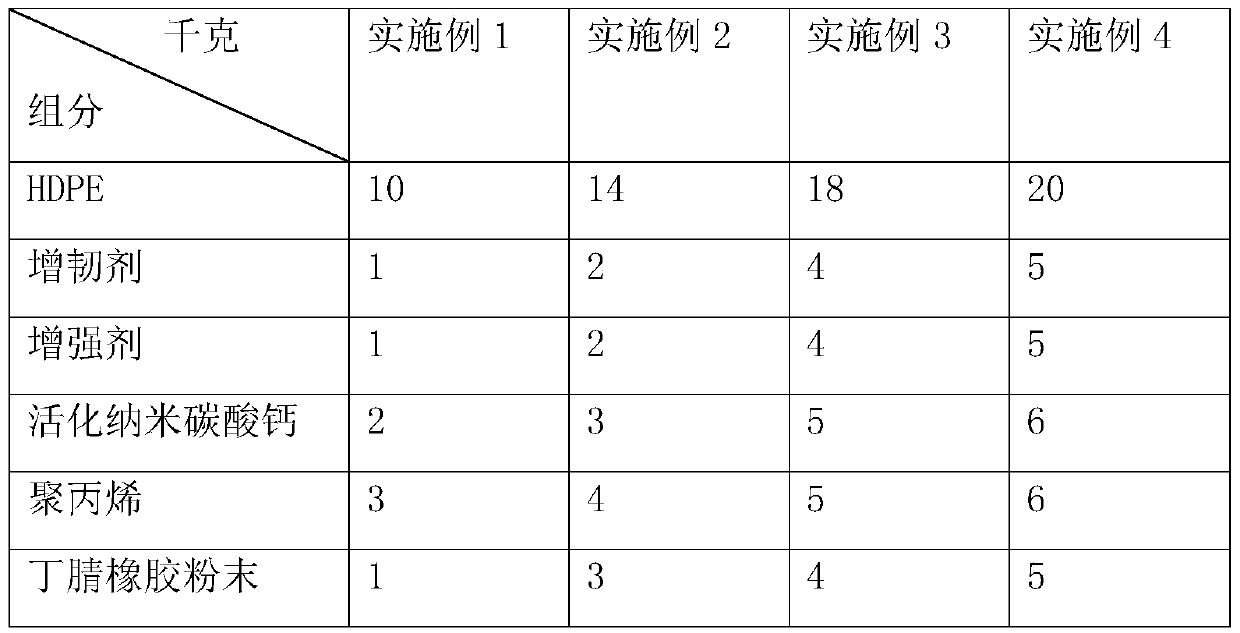

Examples

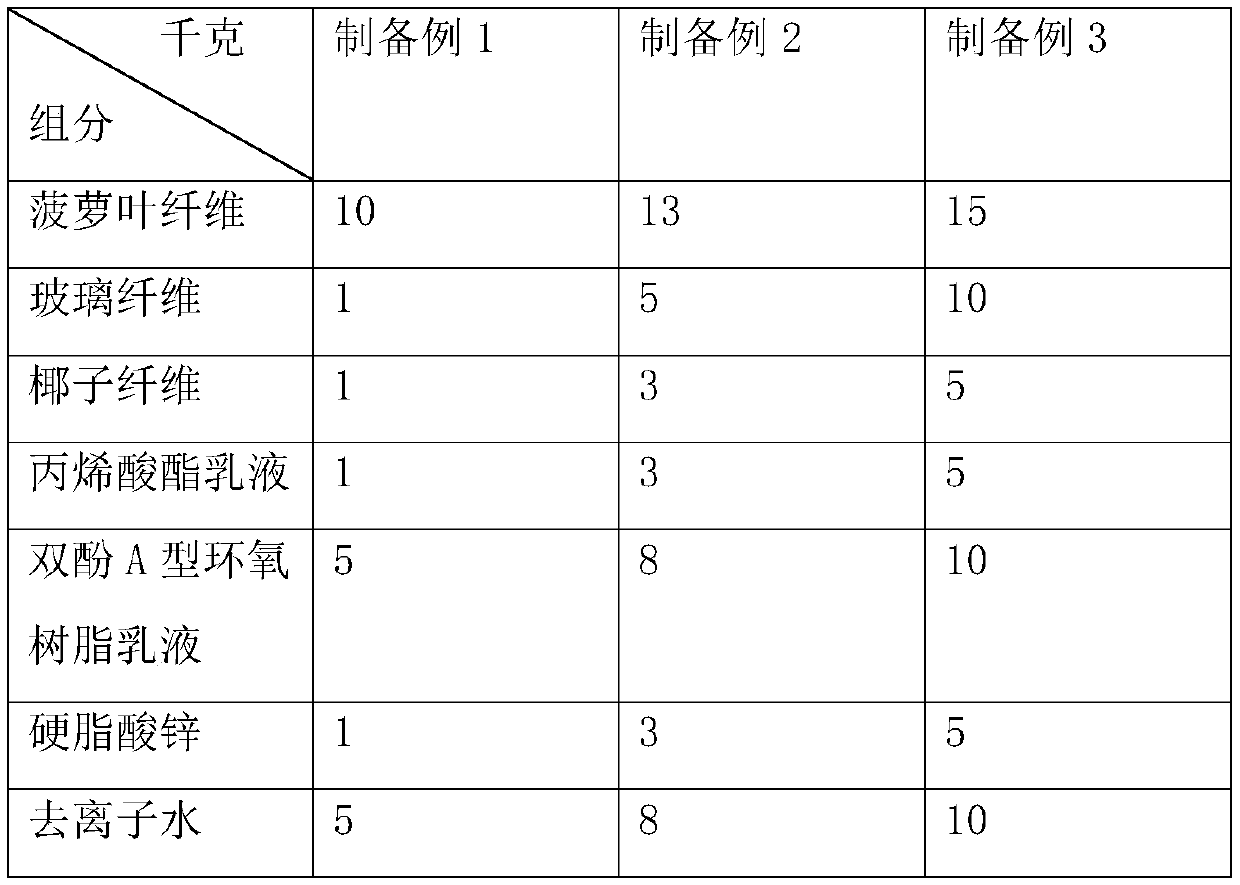

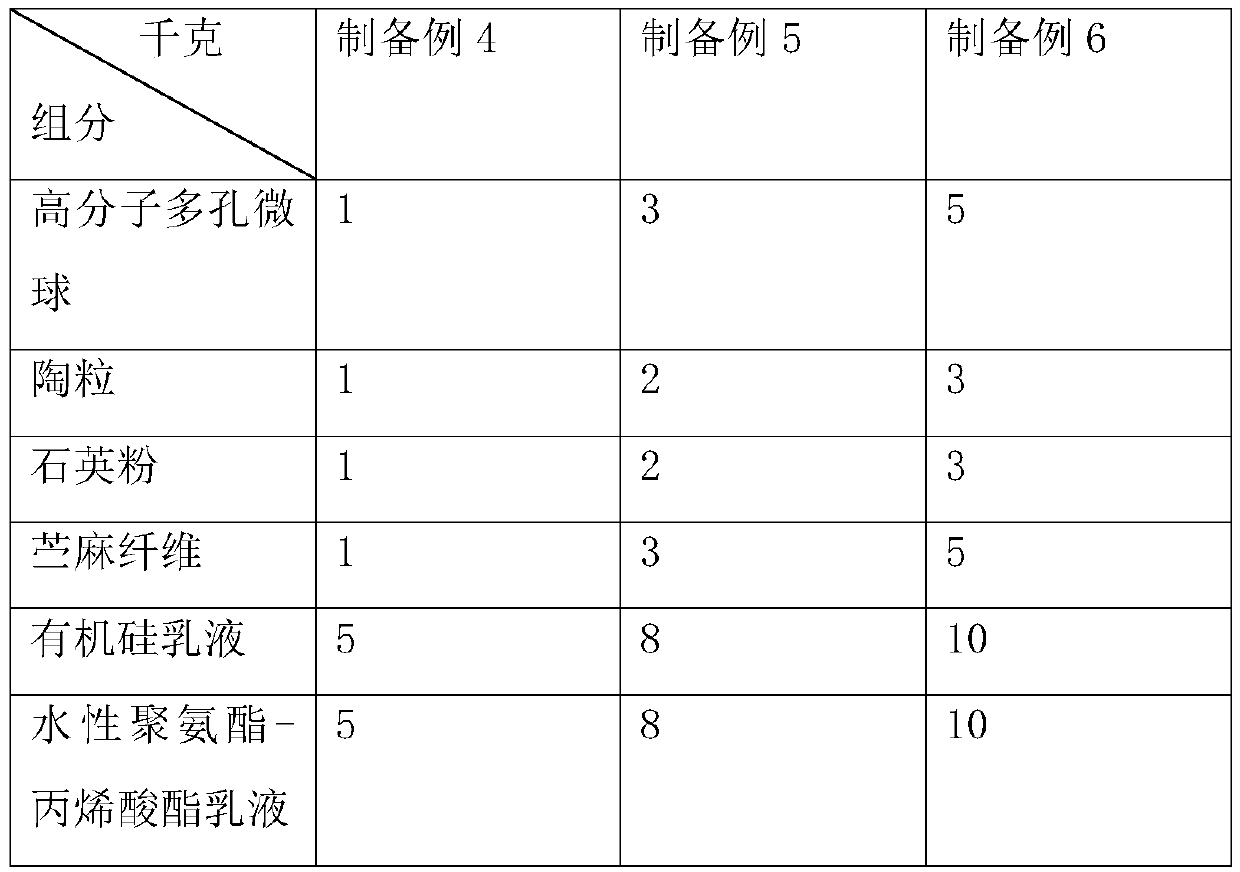

preparation example 1-3

[0042] The acrylate emulsion in the preparation example 1-3 is selected from the td-br type acrylate emulsion sold by Shanxi Zhongyi Tuoda Construction Engineering Materials Co., Ltd., and the bisphenol A epoxy resin emulsion is selected from the TC sold by Jiangyin Wanqian Chemical Co., Ltd. - Bisphenol A universal liquid epoxy resin type K44.

preparation example 1

[0043] Preparation example 1: (1) according to the proportioning in table 1, take by weighing 5kg deionized water, put in the reactor, add 1kg zinc stearate in the reactor, heat to 50 ℃, add 10kg pineapple leaf fiber, 1kg of glass fiber and 1kg of coconut fiber were stirred at a speed of 400r / min until the three fibers were fully dissolved and cooled to room temperature; the pineapple leaf fiber was 3mm in length and 10μm in diameter, and the glass fiber was 1.5mm in length and 10μm in diameter , the coconut fiber has a length of 10mm and a diameter of 1.5μm;

[0044] (2) Mix 1 kg of acrylate emulsion and 5 kg of bisphenol A epoxy resin and heat to 40° C., add the product from step (1), stir at a speed of 200 r / min, and mix well.

[0045] The raw material ratio of toughening agent in the preparation example 1-3 of table 1

[0046]

preparation example 2

[0047] Preparation example 2: (1) Weigh 8kg of deionized water, put it into a reactor, add 3kg of zinc stearate into the reactor, heat to 60°C, add 13kg of pineapple leaf fiber, 5kg of glass fiber and 3kg of coconut fiber, Stir under the rotating speed of 405r / min, fully dissolve to three kinds of fibers, cool to room temperature; Wherein pineapple leaf fiber length is 5mm, and diameter is 13 μm, and glass fiber length is 2.0mm, and diameter is 13 μm, and the length of coconut fiber is 15mm, 2.5 μm in diameter;

[0048] (2) Mix 3 kg of acrylate emulsion and 8 kg of bisphenol A epoxy resin and heat to 45° C., add the resultant from step (1), stir at a speed of 250 r / min, and mix well.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com