A bimetal anti-wind and wave-type phosphorus-locking material and its preparation method and application

An anti-wave and bimetallic technology, applied in the field of water pollution control, can solve the problems of eutrophication and pollution of water bodies, and achieve the effect of alleviating the degree of eutrophication, broad application prospects, and natural non-toxic ecological safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

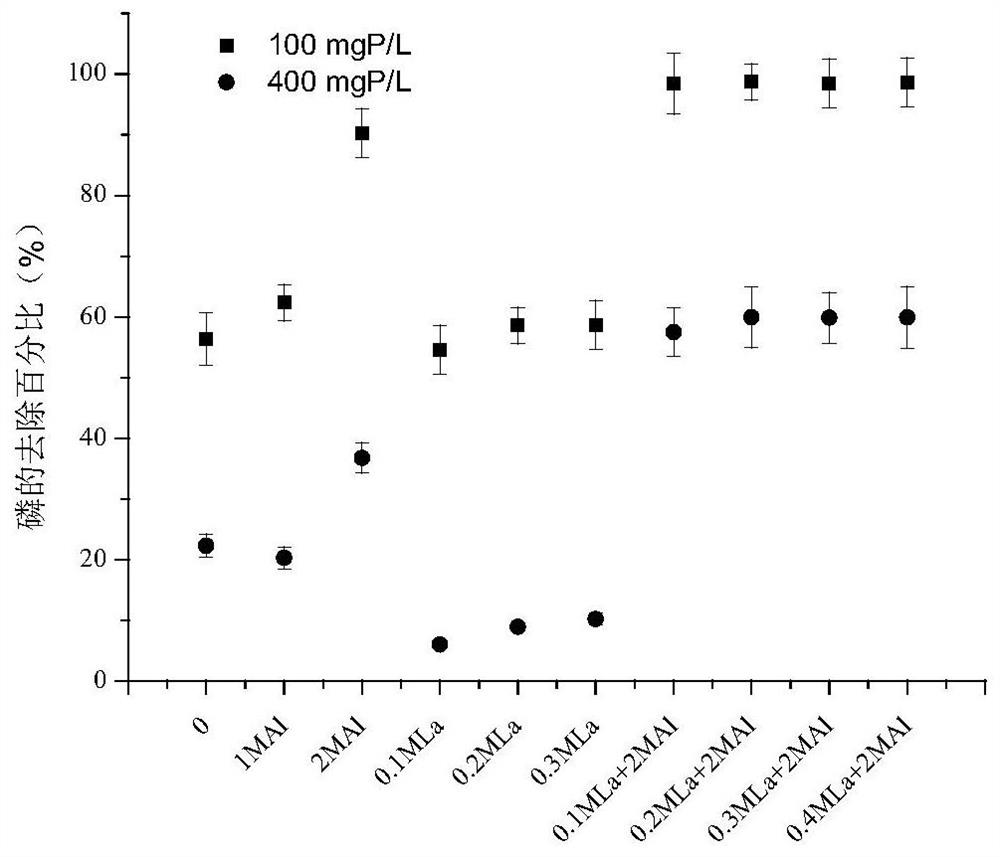

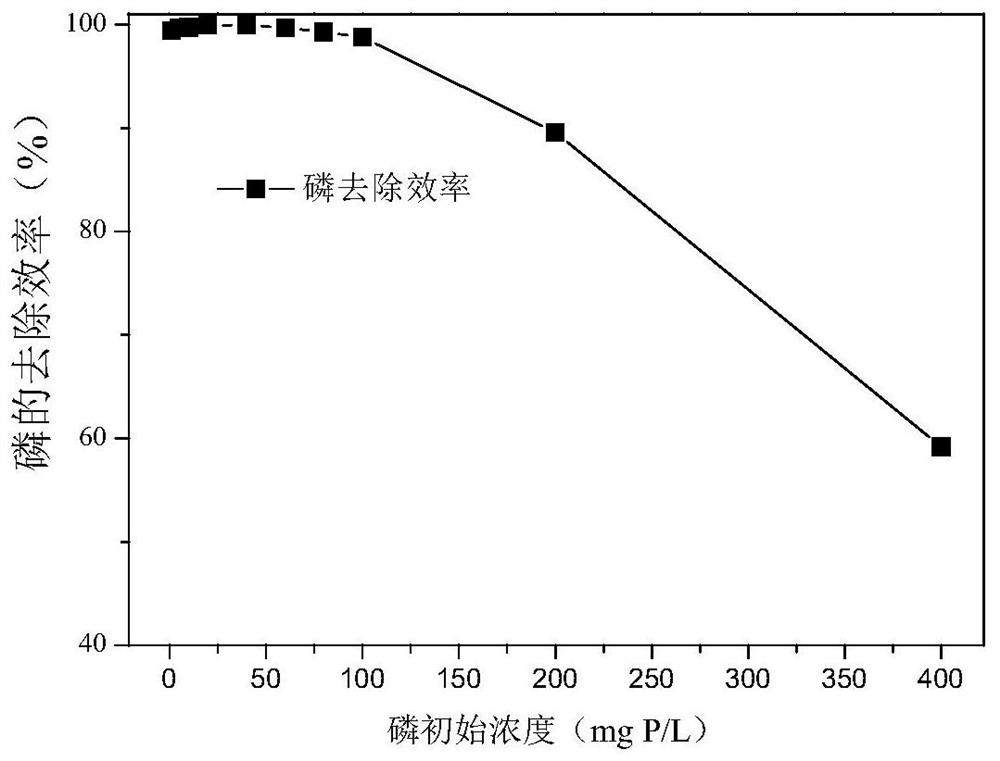

[0032]The dolomite attapulgite powder in the powder state is granulated by drum, and water is used as a granulating agent (with a particle size of 1-2mm), wherein the mass content of the attapulgite is 30%, and the mass content of dolomite is 10%. The granulated dolomite attapulgite clay was calcined at 700 °C for 2 h in a high-temperature calcination furnace. Weigh a certain mass of aluminum chloride hexahydrate and set the volume to 100 mL, and prepare 1mol / L aluminum chloride solution, 2 mol / L aluminum chloride solution, 0.1mol / L lanthanum chloride solution, 0.2mol / L Lanthanum solution, 0.3mol / L lanthanum chloride solution, 2 mol / L aluminum chloride and 0.1mol / L lanthanum chloride mixed solution, 2 mol / L aluminum chloride and 0.2mol / L lanthanum chloride mixed solution, 2 mol / L aluminum chloride and 0.3mol / L lanthanum chloride mixed solution and 2 mol / L aluminum chloride and 0.4mol / L lanthanum chloride mixed solution. Add the materials that have been calcined at high tempe...

Embodiment 2

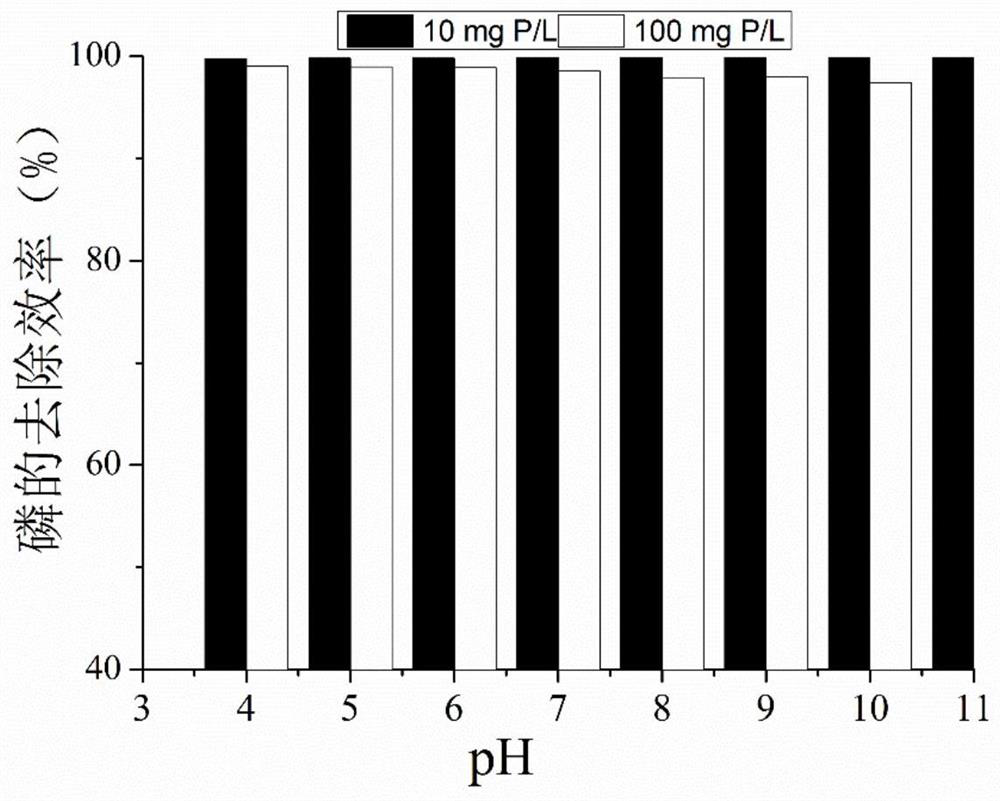

[0039] The dolomite attapulgite powder in the powder state is granulated by drum, and water is used as a granulating agent (with a particle size of 1-2mm), wherein the mass content of the attapulgite is 40%, and the mass content of dolomite is 30%. The granulated dolomite attapulgite clay was calcined at 800 °C for 2 h in a high-temperature calcination furnace. Weigh a certain mass of aluminum chloride hexahydrate and set the volume to 100 mL, and prepare a mixed solution of 2mol / L aluminum chloride and 0.16mol / L lanthanum chloride. Add the materials that have been calcined at high temperature to each of the above mixed solutions according to the ratio of water to soil mass ratio of 1:3, place them in a shaker, shake fully at 27°C (160rpm) for 1 hour, let stand at room temperature for one day, and then discard Remove the upper liquid, age the lanthanum-aluminum-loaded material in an oven at 70°C for 24 h, cool to room temperature, and finally wash the material with water until...

Embodiment 3

[0041] The dolomite attapulgite powder in the powder state is granulated by drum, and water is used as a granulating agent (particle size is 1-2mm), wherein the mass content of attapulgite is 50%, and the mass content of dolomite is 20%. The granulated dolomite attapulgite clay was calcined at 600 °C for 2 h in a high-temperature calcination furnace. Weigh a certain mass of aluminum chloride hexahydrate and set the volume to 100 mL, and prepare a mixed solution of 2mol / L aluminum chloride and 0.2mol / L lanthanum chloride. Add the material that has been calcined at high temperature to the above mixed solution according to the ratio of water to soil mass ratio of 1:2, place it in a shaker, shake it fully at 25°C (160rpm) for 1 hour, let it stand at room temperature for one day, and then discard it For the upper liquid, the lanthanum-aluminum-loaded material was aged in an oven at 50°C for 24 h, cooled to room temperature, and finally the material was washed with water until the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com