Copper-modified nitrogen-doped titanium dioxide material, and preparation method and application thereof

A titanium dioxide and nitrogen doping technology, applied in chemical instruments and methods, chemical/physical processes, special compound water treatment, etc., can solve the problems of reduced production efficiency and long production cycle, and achieve reduced water toxicity and improved photocatalytic efficiency , The effect of strong photocatalytic reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

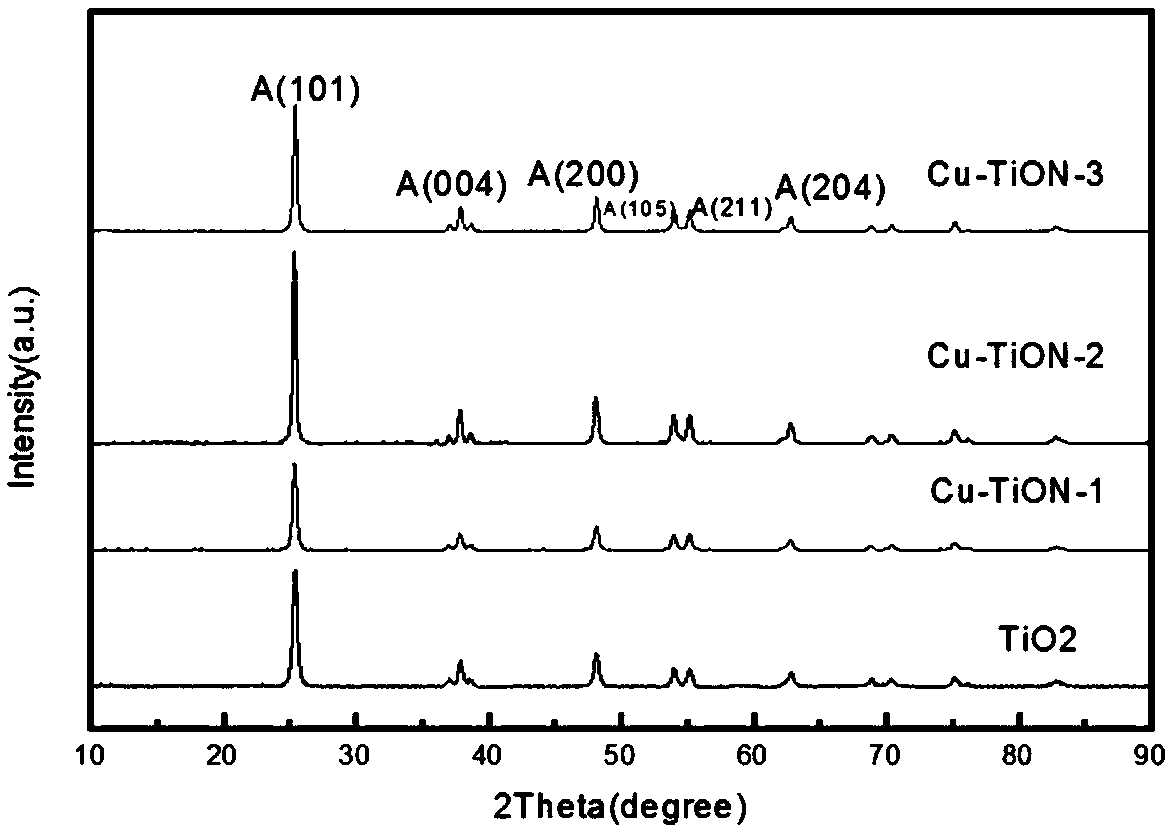

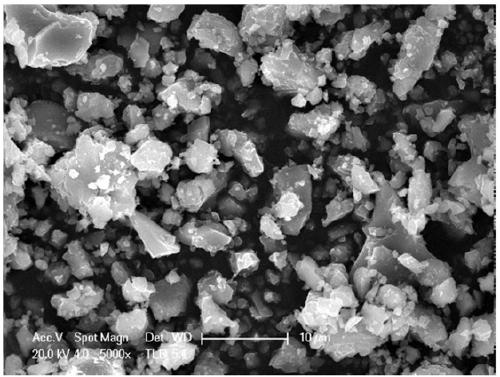

Embodiment 1

[0024] Step (1): Add 3.86mL of dimethylformamide into 30mL of absolute ethanol and stir for 5min under magnetic force to obtain a clear mixed solution.

[0025] Step (2): Add 40 mL of tetrabutyl titanate to the solution obtained in step (1), stir magnetically, and mix evenly to obtain a sol.

[0026] Step (3): In the sol obtained in step (2), add 10 mL of copper chloride absolute ethanol solution with a concentration of 10.6 g / L and 5 mL of lemon Acid aqueous solution, and magnetically stirred to obtain a uniform sol, then dropwise added acetic acid at a rate of 1 drop / second, and adjusted the pH of the system to 3.0.

[0027] Step (4): The sol obtained in step (3) was subjected to ultrasonic treatment to obtain a uniform wet gel. The ultrasonic power was 100 W, the ultrasonic temperature was 50° C., and the ultrasonic time was 10 min.

[0028] Step (5): The wet gel obtained in step (4) was washed three times with absolute ethanol, placed in an oven, and dried at 80 °C for 12...

Embodiment 2

[0032] Step (1): Add 3.86 mL of dimethylformamide into 30 mL of absolute ethanol and stir for 5 min under magnetic force to obtain a clear mixed solution.

[0033] Step (2): Add 40 mL of tetrabutyl titanate into the solution obtained in step (1), stir magnetically, and mix well.

[0034] Step (3): Add 10 mL of copper chloride absolute ethanol solution with a concentration of 21.0 g / L and 5 mL of citric acid with a concentration of 35 g / L dropwise at a rate of 1 drop / second to the sol obtained in step (2). solution, and magnetically stirred to obtain a uniform sol, then dropwise added acetic acid at a rate of 1 drop / second, and adjusted the pH of the system to 3.0.

[0035] Step (4): Ultrasonic treatment is performed on the sol obtained in step (3) to obtain a uniform wet gel. The ultrasonic power is 100 W, the ultrasonic temperature is 50° C., and the ultrasonic time is 10 min.

[0036]Step (5): The wet gel obtained in step (4) was washed three times with absolute ethanol, pl...

Embodiment 3

[0042] Step (1): Add 3.86mL of dimethylformamide into 30mL of absolute ethanol and stir for 5min under magnetic force to obtain a clear mixed solution.

[0043] Step (2): Add 40 mL of tetrabutyl titanate into the solution obtained in step (1), stir magnetically, and mix well.

[0044] Step (3): In the sol obtained in step (2), add 10 mL of copper chloride absolute ethanol solution with a concentration of 32.0 g / L and 5 mL of lemon Acid solution, and magnetically stirred to obtain a uniform sol, then dropwise added acetic acid at a rate of 1 drop / second, and adjusted the pH of the system to 3.0.

[0045] Step (4): The sol obtained in step (3) was subjected to ultrasonic treatment to obtain a uniform wet gel. The ultrasonic power was 100 W, the ultrasonic temperature was 50° C., and the ultrasonic time was 10 min.

[0046] Step (5): The wet gel obtained in step (4) was washed three times with absolute ethanol, placed in an oven, and dried at 80 °C for 12 hours to obtain a coppe...

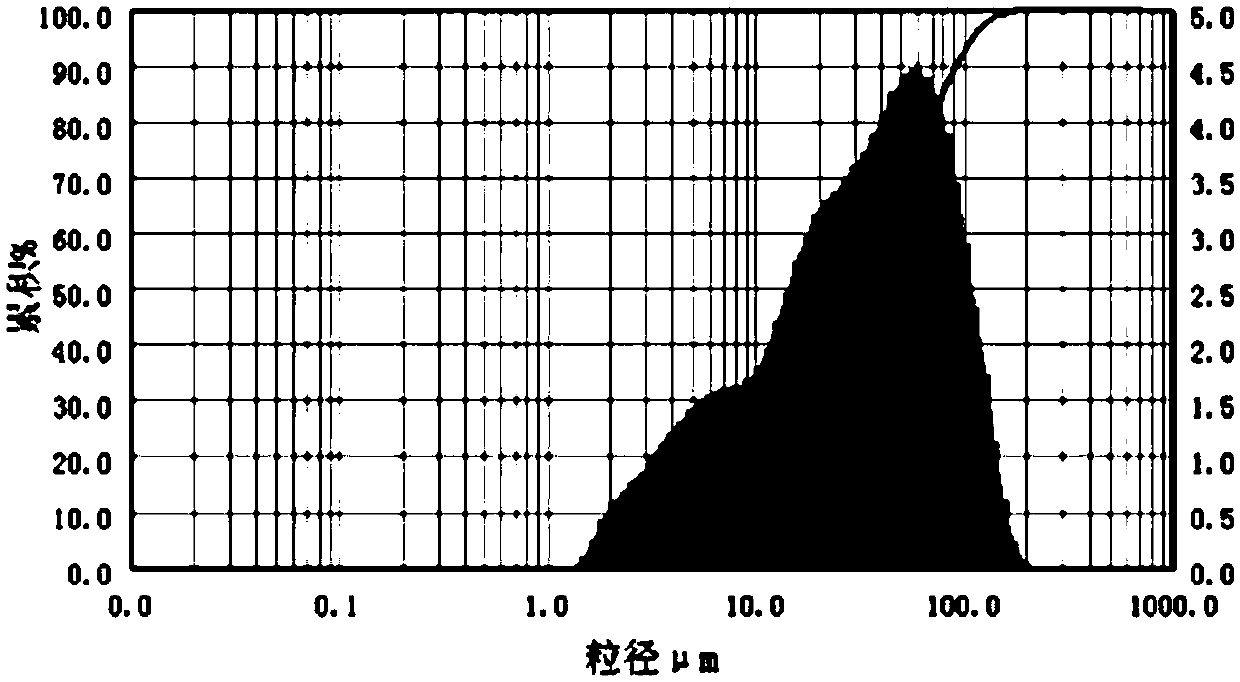

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com