Non-burning self-cleaning permeable brick made of nickel-iron slag and preparation method thereof

A technology of permeable bricks and ferronickel, which is applied in the field of materials, can solve the problems of high temperature calcination and high cost of permeable bricks, and achieve the effects of unbreakable yield, excellent water permeability and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

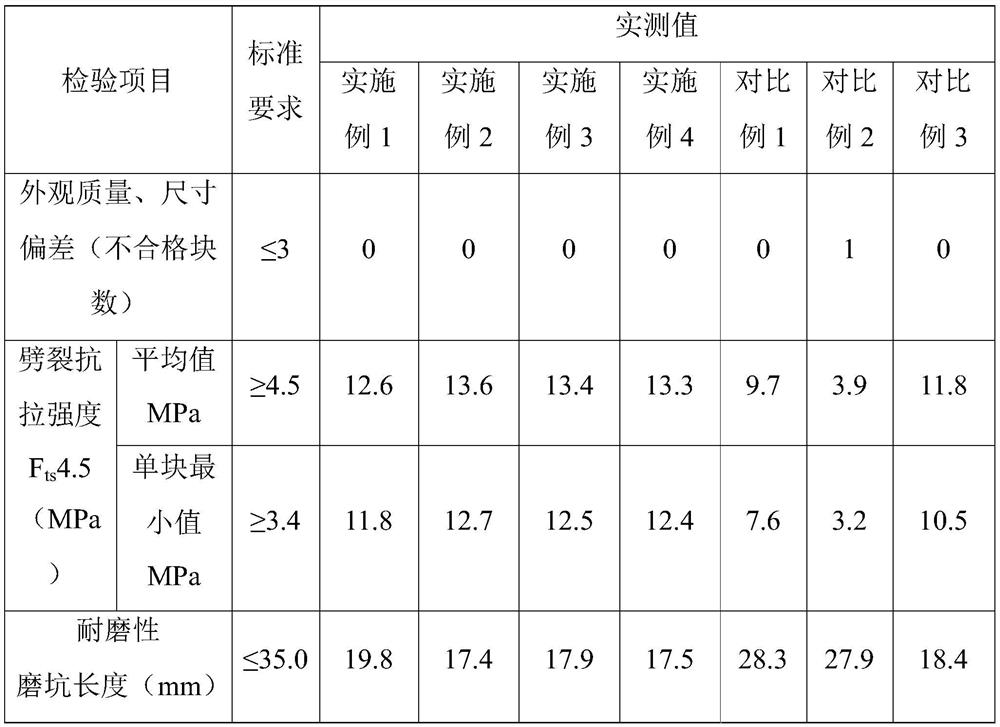

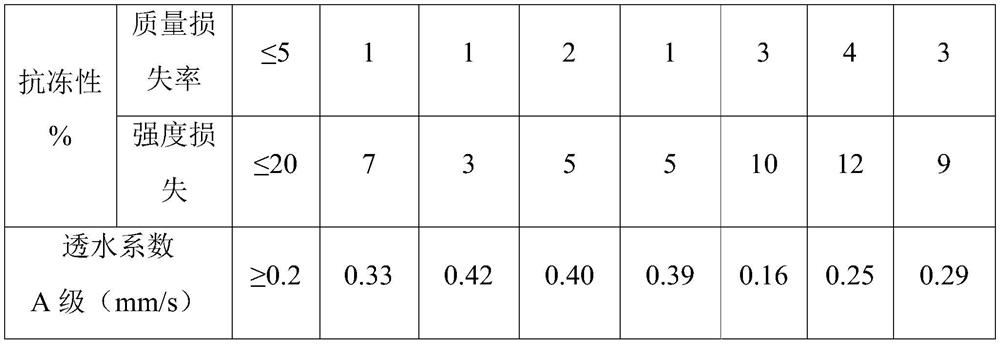

Examples

preparation example Construction

[0022] Wherein, the preparation method of the cement comprises the steps of: mixing water-based acrylate copolymer emulsion, acrylated epoxy resin, stearic acid and magnesium fluorosilicate in a ratio of 1: (0.4-0.6): (0.1-0.2): (0.03 The mass ratio of -0.05) is mixed evenly, and the pH value is adjusted to 4.5-4.8, and then the temperature is raised to 90°C at a heating rate of 1-2°C / min, and the temperature is kept for 50-60min; Cool down to 64-66°C at a cooling rate of 0.7°C / min, keep warm for 20-30min, and then cool down to 20-25°C at a cooling rate of 1.2-1.4°C / min to obtain a cement;

[0023] The preparation method of water-based acrylate copolymer emulsion comprises the steps of: mixing butyl methacrylate, vinyl-terminated polydimethylsiloxane and vinyltrimethoxysilane in a ratio of 1: (1.2-1.3): (0.04-0.06 ) in a mass ratio and mix evenly, adjust the pH value to 8.2-8.4, then heat at 68-70°C for 6-8h, and stir at a rate of 500-800r / min during the heating process to obt...

Embodiment 1

[0030] This embodiment provides a permeable brick, including a base material and a fabric;

[0031] The raw material components of the primer are calculated in parts by weight, including: 85 parts by weight of ferronickel slag, 35 parts by weight of cement, 0.4 parts by weight of cement, 2 parts by weight of water, 0.2 parts by weight of concrete coagulant and 0.3 parts by weight of anti-solvent agent;

[0032] The raw material components of the fabric include, by weight, 85 parts by weight of ferronickel slag, 35 parts by weight of iron oxide and 20 parts by weight of water;

[0033] According to the above-mentioned raw materials, adopt the preparation method provided by the invention to prepare permeable bricks:

[0034] Mix all the raw material components of the base material and stir for 15 minutes, then transfer to the automatic compression molding machine for hydroforming;

[0035] Mix all the raw material components of the fabric and stir for 15 minutes to achieve unif...

Embodiment 2

[0037] This embodiment provides a permeable brick, including a base material and a fabric;

[0038]The raw material components of the primer are calculated in parts by weight, including: 85 parts by weight of ferronickel slag, 35 parts by weight of cement, 0.4 parts by weight of cement, 2 parts by weight of water, 0.2 parts by weight of concrete coagulant and 0.3 parts by weight of anti-solvent agent;

[0039] The raw material components of the fabric include, in parts by weight, 85 parts by weight of ferronickel slag, 35 parts by weight of iron oxide and 20 parts by weight of water;

[0040] Wherein, the preparation method of the cement includes the steps of: uniformly mixing the aqueous acrylate copolymer emulsion, acrylated epoxy resin, stearic acid and magnesium fluorosilicate in a mass ratio of 1:0.5:0.15:0.04, and adjusting the pH value to 4.6, then raise the temperature to 90°C at a heating rate of 1.5°C / min, and hold for 55 minutes; then adjust the pH value to 6.4, coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com