Dispersed fiber foam concrete and preparation method thereof

A technology of fiber foam and concrete, applied in the field of building materials, to achieve the effect of high thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

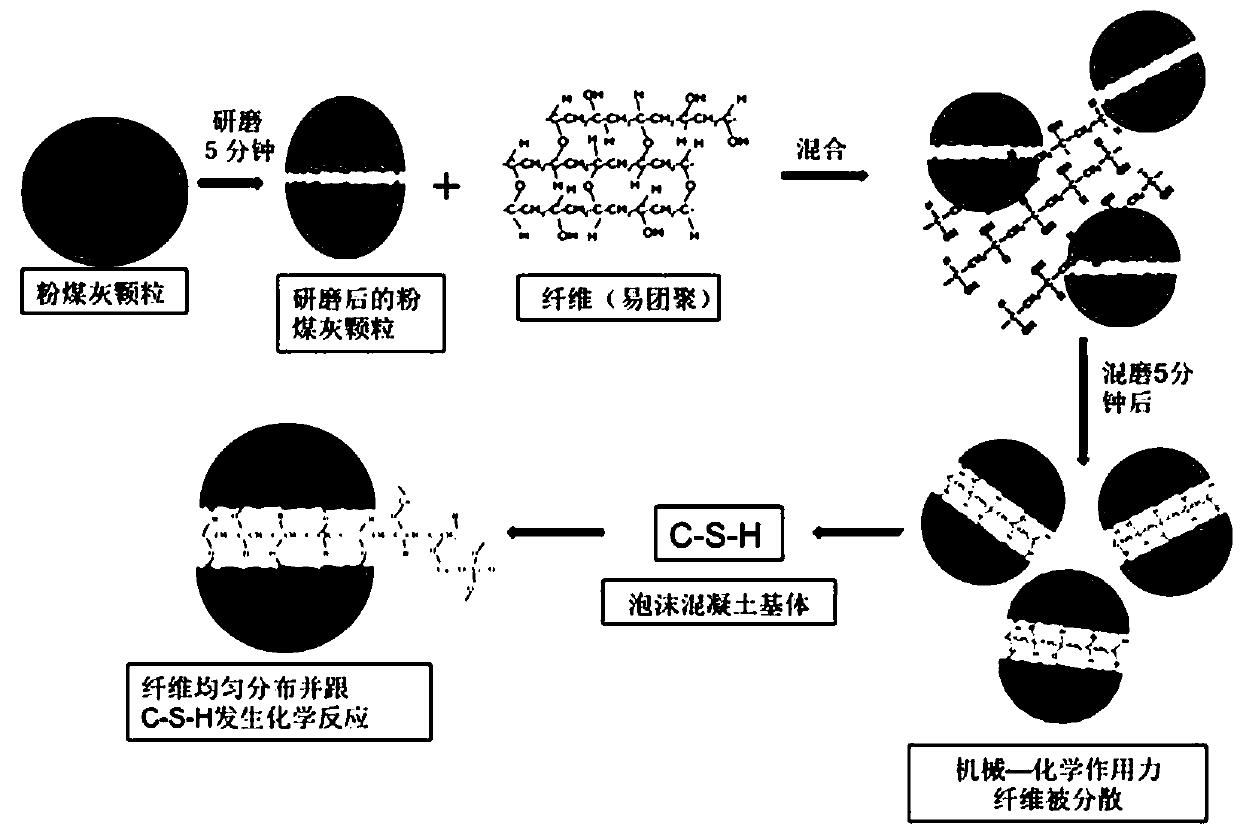

Method used

Image

Examples

preparation example Construction

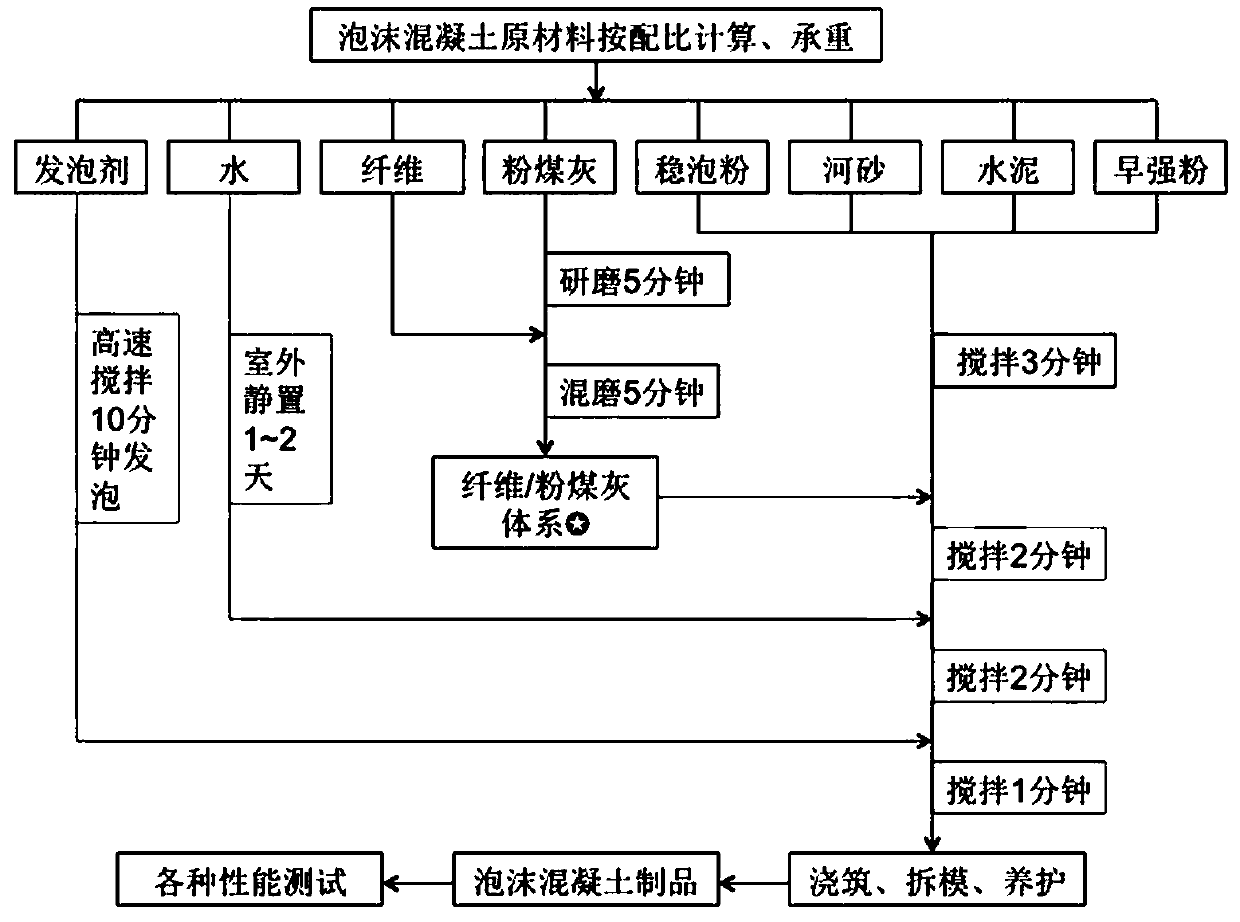

[0029] The preparation method of the aforementioned modified fiber foam concrete of the present invention includes the following steps (accompanying drawing 2 is a schematic diagram of the manufacturing process of the product of the present invention):

[0030] (1) Raw materials and pre-production preparations:

[0031] (1) After weighing the water by more than the above-mentioned parts by weight, place it outdoors for 1 to 2 days, and set it aside;

[0032] (2) Wash and sieve the river sand, select the river sand with a particle size of ≤0.3 mm, and place it in a drying box and bake it at 105°C until it reaches a constant weight, and set aside;

[0033] (2) Production of modified fiber foam concrete:

[0034] (1) Calculate the parts by weight of cement, river sand, early-strength powder, foam-stabilizing powder, fly ash, fiber, water, and foaming agent used each time according to the design requirements of the dry density of the product;

[0035] (2) Input the fly ash into ...

Embodiment 1

[0041] To produce 1 cubic meter of modified fiber foam concrete test block with a dry density of 500kg / m3, the amount of raw materials required for production: cement (P.O 42.5) 250.02 kg; river sand (particle size ≤ 0.3 mm) 83.34 kg; fly ash (I grade) 83.34 kg; water 208.35 kg; polyvinyl alcohol (PVA) fiber (fiber length 9 mm, diameter 31 microns) 1.50 kg; early strength agent calcium formate, molecular formula C2H2CaO4, dosage 1.25 kg; polymer foam The dosage of the agent is 2.92 kg; the foam stabilizer is polyacrylamide, and the dosage is 0.5 kg.

[0042] The production steps of the products are attached figure 2 conduct.

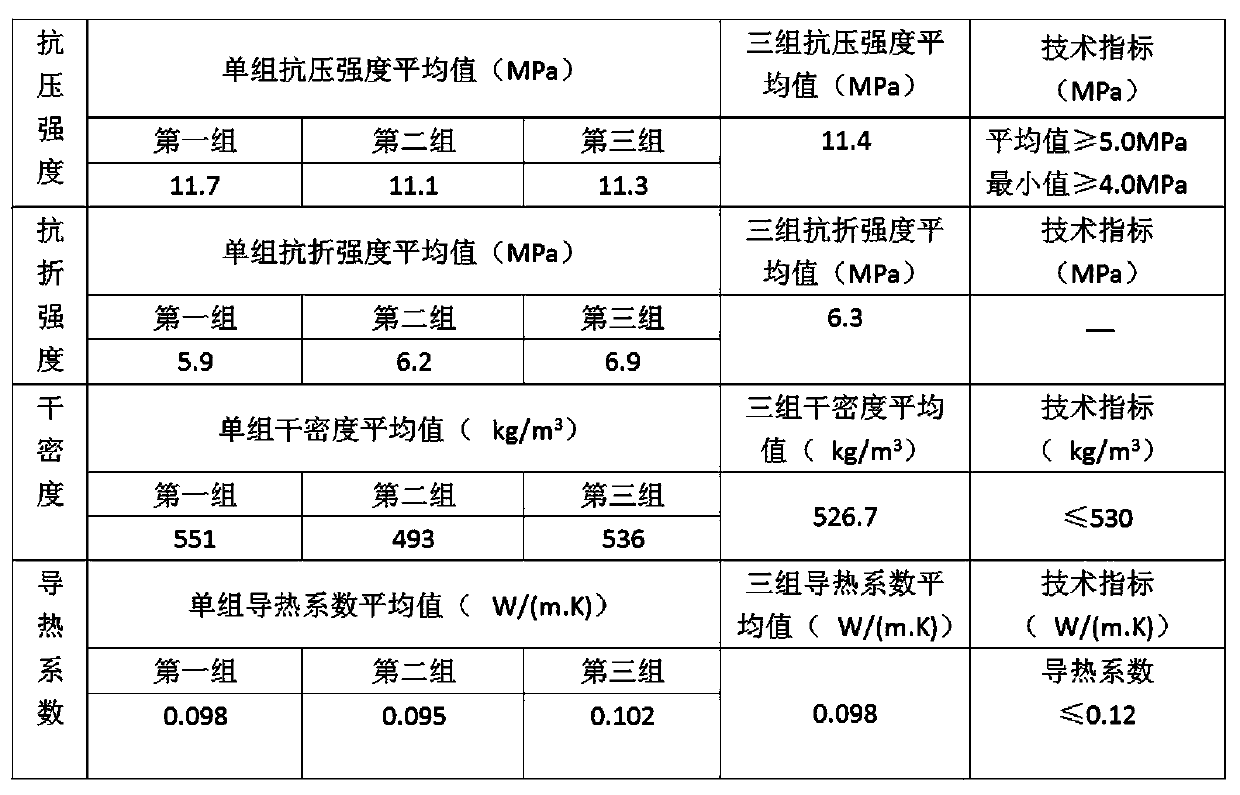

[0043] The modified fiber foam concrete insulation test block prepared in the embodiment is tested according to the specifications "JC / T 1062-2007" and the specification "GB / T 11969-2008" for dry density, strength, insulation performance and other properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com