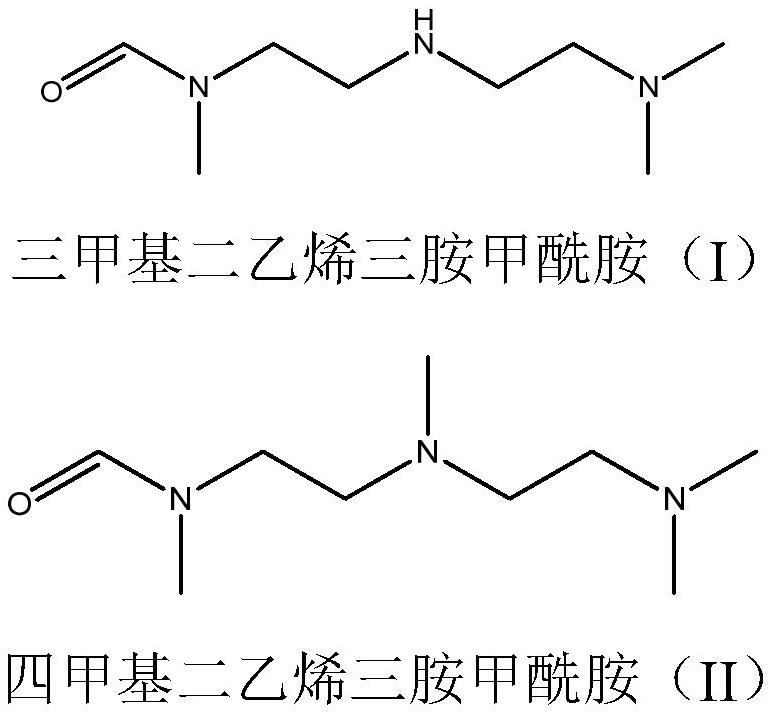

Method for continuous preparation of pentamethyldiethylenetriamine and catalyst system for the method

The technology of pentamethyldiethylenetriamine and diethylenetriamine is applied in the field of preparation of polyurethane catalysts, and can solve the problems of low pentamethyldiethylenetriamine yield, great environmental hazard of catalysts, easy decomposition of products, and the like, Achieve the effect of high degree of automation, low production cost, not easy to crush and lose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

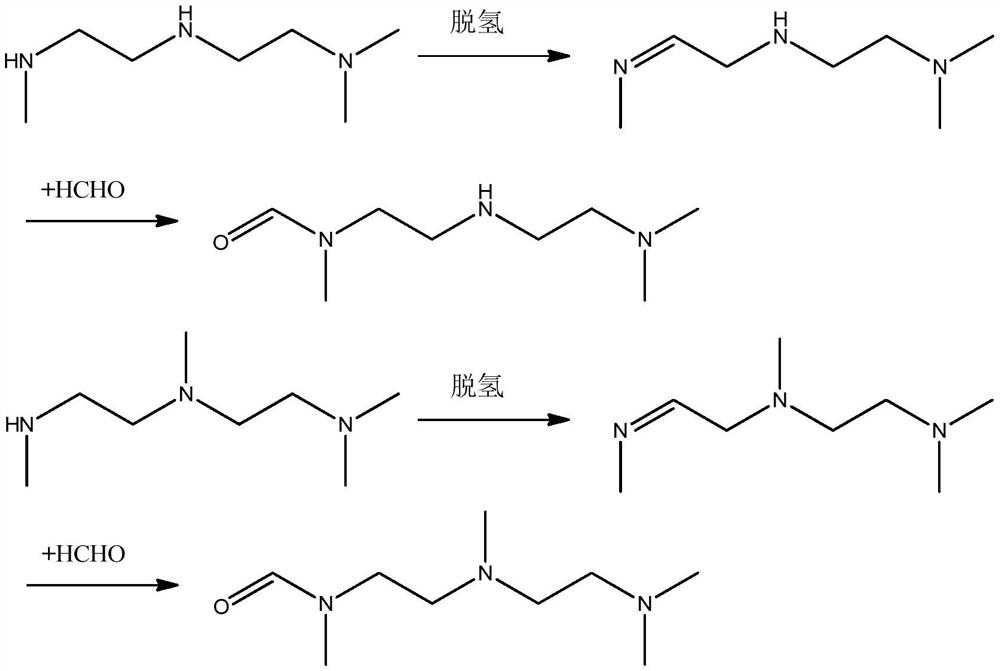

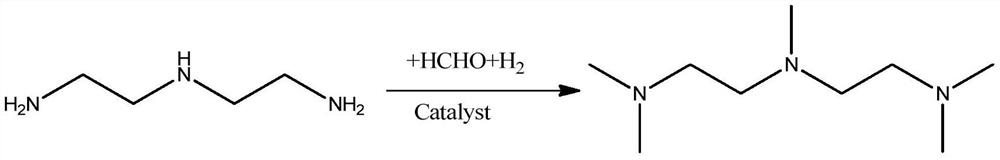

Method used

Image

Examples

Embodiment 1

[0047] Preparation of 1# supported copper-based catalyst precursor:

[0048] Spherical γ-Al 2 o 3 (particle size 3mm, specific surface area 280m 2 / g) Calcined at 450°C for 4h. Prepare a nitrate dipping solution containing 10g copper, 0.1g hafnium and 0.5g zinc with 100ml deionized water, heat to 80°C to form a homogeneous solution, then add 89.4g γ-Al 2 o 3 Carrier, impregnated at 80°C for 12 hours, then baked in an oven at 120°C for 12 hours; finally moved to a muffle furnace, heated at 2-3°C / min to 450°C for 8 hours in an air atmosphere, and cooled naturally The 1# supported copper-based catalyst precursor was obtained. The composition of the catalyst is: copper is 10wt%, hafnium is 0.1wt%, zinc is 0.5wt%, and the rest is γ-Al 2 o 3 , calculated by the corresponding metal element in the total mass of the catalyst.

[0049] Preparation of 1# supported palladium-based catalyst precursor:

[0050] Spherical γ-Al 2 o 3 (particle size 3mm, specific surface area 280m ...

Embodiment 2

[0054] Preparation of 2# supported copper-based catalyst precursor:

[0055] Spherical γ-Al 2 o 3 (particle size 3mm, specific surface area 280m 2 / g) Calcined at 450°C for 4h. Prepare a nitrate dipping solution containing 5g copper, 0.2g hafnium and 1g zinc with 100ml deionized water, heat to 80°C to form a homogeneous solution, then add 93.8gγ-Al 2 o 3 Carrier, impregnated at 80°C for 12 hours, then baked in an oven at 120°C for 12 hours; finally moved to a muffle furnace, heated at 2-3°C / min to 400°C for 6 hours in an air atmosphere, and cooled naturally The 2# supported copper-based catalyst precursor was obtained. The composition of the catalyst is: copper is 5wt%, hafnium is 0.2wt%, zinc is 1wt%, and the rest is γ-Al 2 o 3 , calculated by the corresponding metal element in the total mass of the catalyst.

[0056] Preparation of 2# supported palladium-based catalyst precursor:

[0057] Spherical γ-Al 2 o 3 (particle size 3mm, specific surface area 280m 2 / g) Ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com