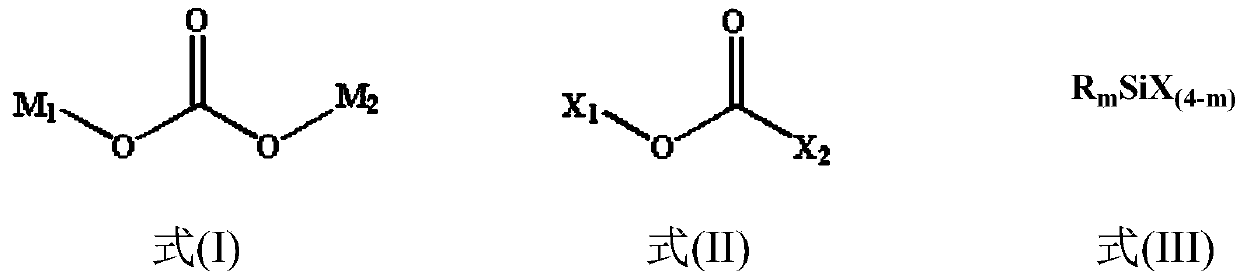

Silicon-containing organic compound and application thereof

A technology of organic compounds and compounds, applied in the direction of silicon organic compounds, organic chemistry, organic electrolytes, etc., can solve problems such as unsatisfactory, potential safety hazards, poor heat dissipation, etc., and achieve the effects of reducing flammability, reducing viscosity, and improving high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

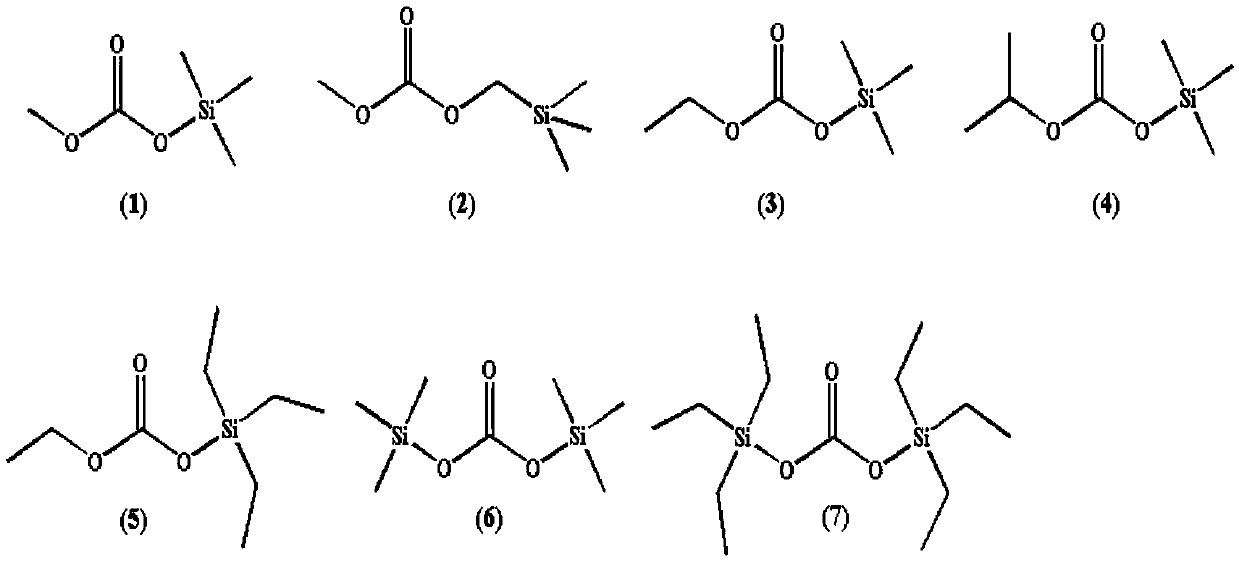

Method used

Image

Examples

Embodiment 1-1

[0048] Electrolyte preparation steps: In a glove box filled with argon, ethylene carbonate (EC), propylene carbonate (PC), ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) were mixed according to the weight ratio of 25:5 : 50:20 ratio is mixed, then add the organosilicon solvent shown in the compound (1) based on the total mass of solvent 5wt% to the mixed solvent, and slowly add 12.5wt% lithium hexafluorophosphate, after that, add mass The fraction is 0.5% of vinylene carbonate (VC), 1.5% of 1,3-propane sultone (1,3-PS), 2% of fluoroethylene carbonate (FEC), and the examples are obtained after stirring evenly 1-1 Lithium-ion battery electrolyte.

[0049] Inject the prepared non-aqueous electrolyte for lithium-ion batteries into fully dried 4.7V LiNi 0.5 mn 1.5 o 4 After the / AG soft-pack battery was put on hold at 45°C, formed in a high-temperature fixture, and sealed twice, the battery performance test was carried out to obtain the battery used in Example 1-1.

Embodiment 1-2 to Embodiment 1-14

[0050] Embodiment 1-2 to embodiment 1-14 and comparative example 1 to comparative example 2

[0051] In Example 1-2 to Example 1-14, except that the proportions of the components of the electrolyte are added as shown in the table below, the others are the same as in Example 1-1, see Table 1.

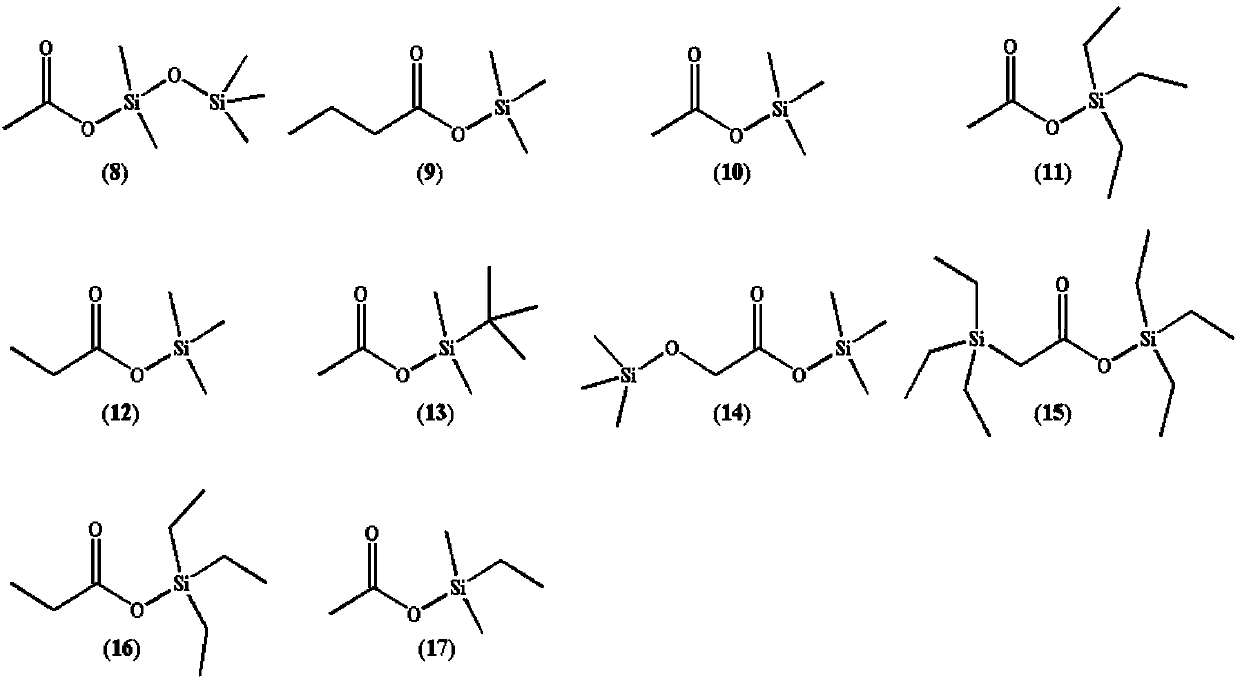

Embodiment 2-1

[0057] Electrolyte preparation steps: In a glove box filled with argon, ethylene carbonate (EC), propylene carbonate (PC), ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) were mixed according to the weight ratio of 25:5 : 50:20 ratio is mixed, then add the organosilicon carboxylate solvent shown in the compound (8) based on the total mass of solvent 5wt% to the mixed solvent, and slowly add 12.5wt% lithium hexafluorophosphate, after that, add to the electrolyte Add mass fraction of 0.5% vinylene carbonate (VC), 1.5% 1,3-propane sultone (1,3-PS), 2% fluoroethylene carbonate (FEC), stir well Obtain the lithium-ion battery electrolyte of Example 2-1.

[0058] Inject the prepared non-aqueous electrolyte for lithium-ion batteries into fully dried 4.7V LiNi 0.5 mn 1.5 o 4 After the / AG soft-pack battery was put on hold at 45°C, formed in a high-temperature fixture, and sealed twice, the battery performance test was carried out to obtain the battery used in Example 2-1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com