Novel environmentally friendly foaming agent and preparation method thereof

A foaming agent, environmental protection technology, applied in the field of new environmental protection foaming agent and its preparation, can solve the problems of high production cost, limited application, long decomposition temperature range, etc., achieve low production cost, broad market prospect, high decomposition temperature short-term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

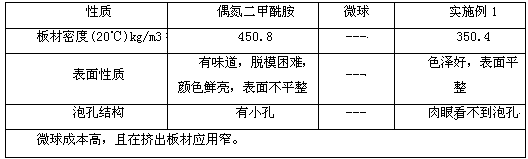

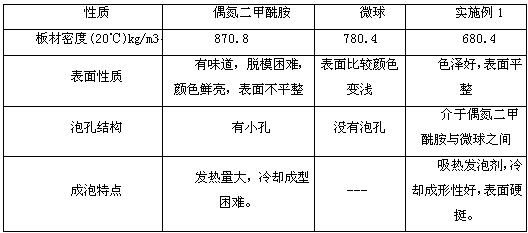

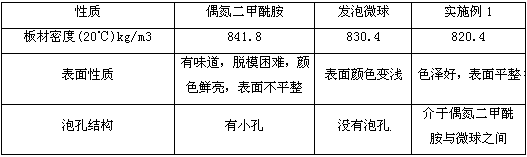

Examples

Embodiment 1

[0024] A novel environment-friendly blowing agent, its preparation method is as follows:

[0025] (1) Prepare sodium bicarbonate powder;

[0026] S1, take by weighing the sodium bicarbonate of 100kg, under dry condition, pulverize after pulverizer, obtain sodium bicarbonate powder, the average particle diameter of sodium bicarbonate is 10 μ m;

[0027] S2, in the sodium bicarbonate powder agitator obtained in S2, adopt pressurized nozzle to spray liquid paraffin spray to the surface of sodium bicarbonate powder;

[0028] S3. Mix the sodium bicarbonate powder and the liquid paraffin in a stirrer, the speed of the stirrer is 100 rpm, and the stirring time is 10 min.

[0029] Among them, S2 and S3 are performed simultaneously.

[0030] (2) Prepare foaming agent;

[0031] Weigh 5 kg of crushed citric acid in a blender, the average particle size of the crushed citric acid is 10 μm, add 2 kg of calcium hardate to the blender, stir for 3 min at a speed of 100 rpm, and add 3 kg of ...

Embodiment 2

[0033] (1) Prepare sodium bicarbonate sodium bicarbonate powder;

[0034] S1, take by weighing the sodium bicarbonate of 100kg, under dry condition, pulverize after pulverizer, obtain sodium bicarbonate powder, the average particle diameter of sodium bicarbonate is 10 μ m;

[0035] S2, in the sodium bicarbonate powder agitator obtained in S2, adopt pressurized nozzle to spray liquid paraffin spray to the surface of sodium bicarbonate powder;

[0036] S3. Mix the sodium bicarbonate powder and the liquid paraffin in a stirrer, the speed of the stirrer is 100 rpm, and the stirring time is 10 min.

[0037] Wherein, S3 is performed after S2.

[0038] (2) Preparation of foaming agent

[0039] Weigh 5 kg of crushed citric acid in a blender, the average particle size of the crushed citric acid is 10 μm, add 5 kg of calcium hardate to the blender, stir for 5 min at a speed of 100 rpm, add (1) The sodium bicarbonate powder 90kg that prepares in, under the rotating speed condition of ...

Embodiment 3

[0041] A novel environment-friendly blowing agent, its preparation method is as follows:

[0042] (1) Prepare sodium bicarbonate powder;

[0043] S1, take by weighing the sodium bicarbonate of 100kg, under dry condition, pulverize after pulverizer, obtain sodium bicarbonate powder, the average particle diameter of sodium bicarbonate is 10 μ m;

[0044] S2, in the sodium bicarbonate powder agitator obtained in S2, adopt pressurized nozzle to spray liquid paraffin spray to the surface of sodium bicarbonate powder;

[0045] S3. Mix the sodium bicarbonate powder and the liquid paraffin in a stirrer, the speed of the stirrer is 100 rpm, and the stirring time is 10 min.

[0046] Among them, S2 and S3 are performed simultaneously.

[0047] (2) Prepare foaming agent;

[0048] Weigh 5 kg of crushed citric acid in a blender, the average particle size of the crushed citric acid is 10 μm, add 5 kg of calcium oxide to the blender, continue stirring for 3 min at a speed of 100 rpm, add (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com