Method for dyeing fabric with plant dye

A fabric dyeing and vegetable dye technology, applied in the field of printing and dyeing, can solve the problems of large consumption of chemical auxiliaries and energy, low dye utilization rate and high dyeing temperature, achieve significant economic and environmental value, avoid metal pollution, and avoid harmful substances. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

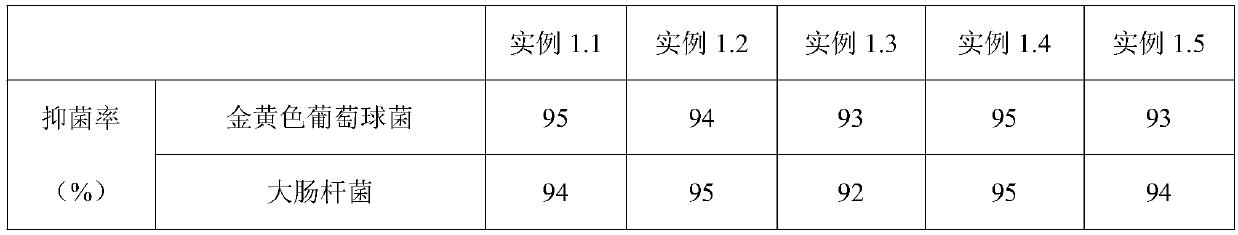

Embodiment 1

[0024] This example relates to the dyeing of fabrics with vegetable dyes.

Embodiment 11

[0026] Get an appropriate amount of turmeric, it is pulverized and screened out and the particle size is 80 mesh turmeric powder, adding pH to the turmeric powder is 5 acetic acid and sodium acetate buffer solution in the ratio of solid-liquid ratio (m:m) 8g: 200g, and Add 20g / L sodium lauryl sulfate, extract at 100°C and 100r / min for 1 hour, filter the extract to obtain the dye mother liquor, and use the dye mother liquor as the dye liquor.

[0027] Take 15g of sodium carbonate and 10g of cleaning agent to make 1L of pretreatment solution, soak the cotton fabric into the pretreatment solution, and then wash it under the conditions of bath ratio (m:m) 1:20, temperature 80°C, time 30-60min. Under preprocessing.

[0028] Soak the pretreated cotton fabric in the dyeing liquor, and add 15g / L dyeing auxiliaries in the dyeing liquor, wherein the dyeing auxiliaries include: sodium lauryl sulfate 2.5g, sodium acetate 5.5g, acetic acid 3g, Sodium chloride 4g, ultrasonic dyeing under t...

Embodiment 12

[0031] Take an appropriate amount of hematoxylin, pulverize it and screen the hematoxylin powder with a particle size of 100 mesh, add acetic acid and sodium acetate buffer with a pH of 6 to the hematoxylin powder according to the ratio of solid-liquid ratio (m:m) 8g:160g Solution, and add 20g / L sodium pyrophosphate, extract at 90°C, 90r / min for 1.2h, filter the extract to obtain the dye mother liquor, and use the dye mother liquor as the dye liquor.

[0032] Take 15g of sodium carbonate and 10g of detergent to make 1L of pretreatment liquid, soak the cotton fabric into the pretreatment lotion, and then wash it under the conditions of liquor ratio (m:m) 1:20, temperature 80°C, and time 50min. Do preprocessing.

[0033] Soak the pretreated cotton fabric in the dye solution, and add 18g / L dyeing auxiliaries to the dye solution, wherein the dyeing auxiliaries include: sodium lauryl sulfate 3.5g, sodium acetate 6.0g, acetic acid 4.5g , sodium chloride 4g, ultrasonic dyeing under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com