Standardized discharge treatment device for high concentration VOCs tail gas based on condensing catalytic oxidation

A technology of catalytic oxidation and treatment device, which is applied in gas treatment, vapor condensation, chemical instruments and methods, etc., can solve the problems of difficult discharge of organic waste gas and high operating energy consumption, and achieves saving functional consumption, low installed power, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

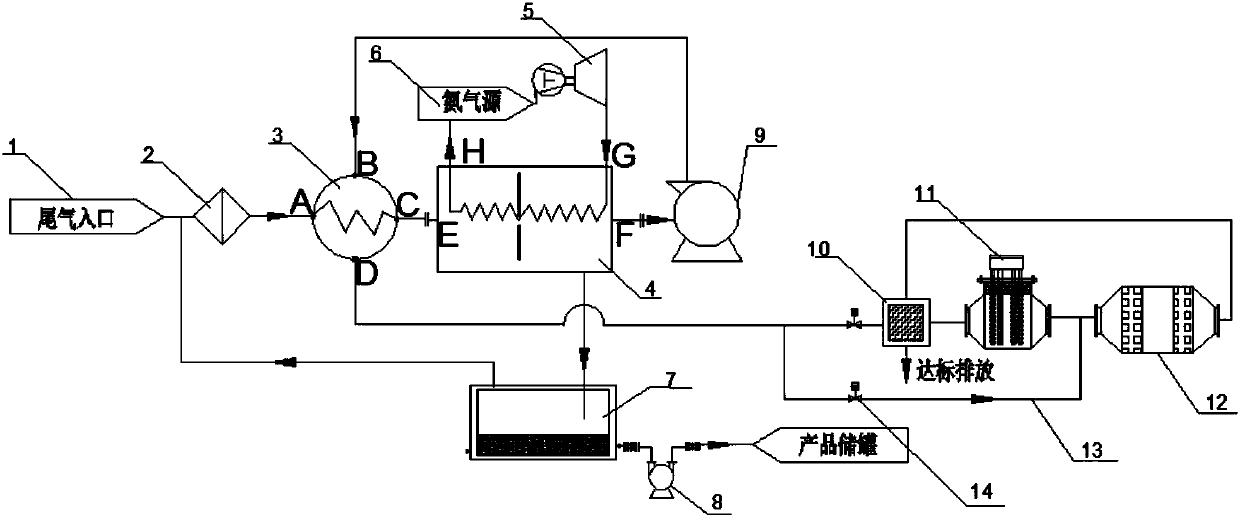

[0020] The present invention will be further described now in conjunction with accompanying drawing. The accompanying drawings are simplified schematic diagrams only illustrating the basic structure of the present invention in a schematic manner, so that they only show components relevant to the present invention.

[0021] Such as figure 1 As shown, a high-concentration VOCs tail gas emission treatment device based on condensation catalytic oxidation, including a condensation system, a catalytic oxidation system, and piping and valves connected between the above systems; the condensation system includes an exhaust gas inlet 1, a flame arrester 2 , cooling capacity exchanger 3, cold box 4, expander 5, nitrogen source 6, condensate recovery tank 7, liquid guide pump 8, high-pressure air pump 9, described catalytic oxidation system includes preheater 10, electric heater 11 , catalytic reactor 12; the expander 5 inlet is connected with the nitrogen source 6, the expander 5 outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com