Preparation method and application of polystyrene macroreticular resin containing multiple phenolic hydroxyl groups

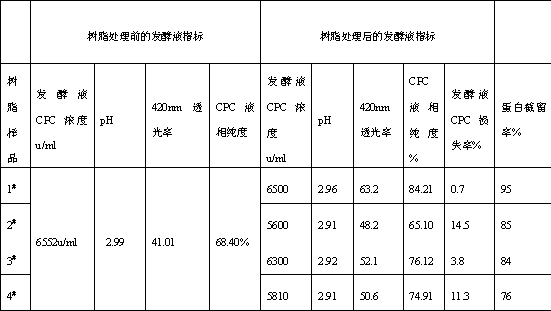

A technology containing polyphenolic hydroxyl groups and polystyrene, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of rapid resin decay, difficult regeneration, and low adsorption capacity. The effect of long service life, stable performance and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

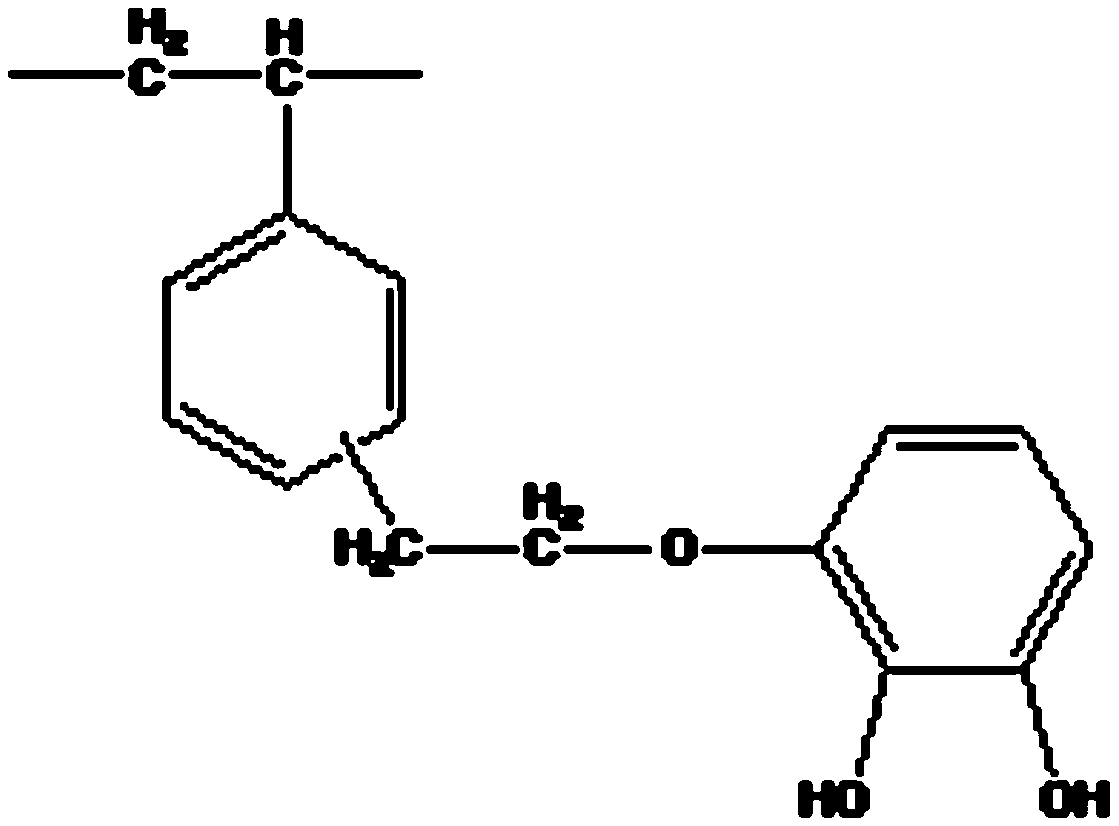

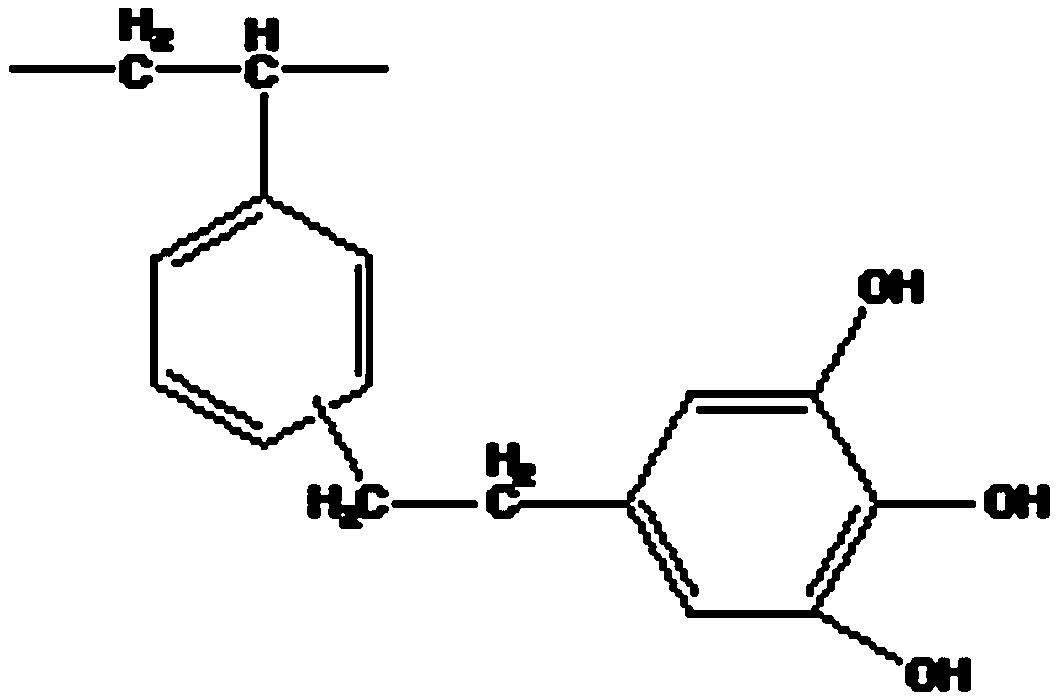

[0032] The preparation method of polystyrene-based macroporous adsorption resin containing polyphenolic hydroxyl groups is characterized in that the preparation method is a one-pot preparation method, including: aqueous phase preparation, organic phase preparation, distillation, and water washing;

[0033] Specifically: add 14.5g of gelatin dispersant to 1450g of water, heat up to 40-45°C to dissolve for 30 minutes, cool to room temperature, add 1.4g of sodium hydroxide and 2.44g of boric acid, and measure the pH of the solution to be 10.2. Mix the organic phase containing 20g styrene, 180g divinylbenzene, 180g isobutanol, 150g toluene, and 2g benzoyl peroxide initiator 1 into the water phase, disperse into balls, adjust the speed and uniform particle size, and then heat up Up to the reaction temperature, suspension polymerization was carried out, and the reaction was carried out at 78° C. for 2 hours. React at 85-95°C for 14 hours. After the heat preservation is over, wash wi...

Embodiment 2

[0035] Specifically: Add 18g of gelatin dispersant to 1800g of water, heat up to 40-45°C to dissolve for 30 minutes, cool to room temperature, add 1.4g of sodium hydroxide and 2.44g of boric acid, and measure the pH of the solution to be 10.1. Mix the organic phase containing 10g styrene, 190g divinylbenzene, 200g methyl isobutyl carbinol, 200g toluene, and 3g benzoyl peroxide initiator 1 into the water phase, disperse into balls, and adjust the speed After the particle size is uniform, the temperature is raised to the reaction temperature for suspension polymerization, and the reaction is carried out at 78°C for 2 hours. React at 85-95°C for 14 hours. After the heat preservation is over, wash with 1000g of anhydrous salt water for two to three times each time, and then turn on steam distillation. After all the porogens are evaporated, cool down to 40-45°C, and add over Oxidize 2 g of benzoyl and 200 g of pyrogallol, raise the temperature to 75-80° C., react for 12-16 hours, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com