Interface agent for mechanized construction

A technology of interface agent and machine-made sand, applied in construction, building structure, covering/lining, etc., can solve the problems of construction team's nest work, slow water absorption of concrete walls, etc., to ensure adhesion and reduce hollowing phenomenon , to avoid the effect of rapid water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

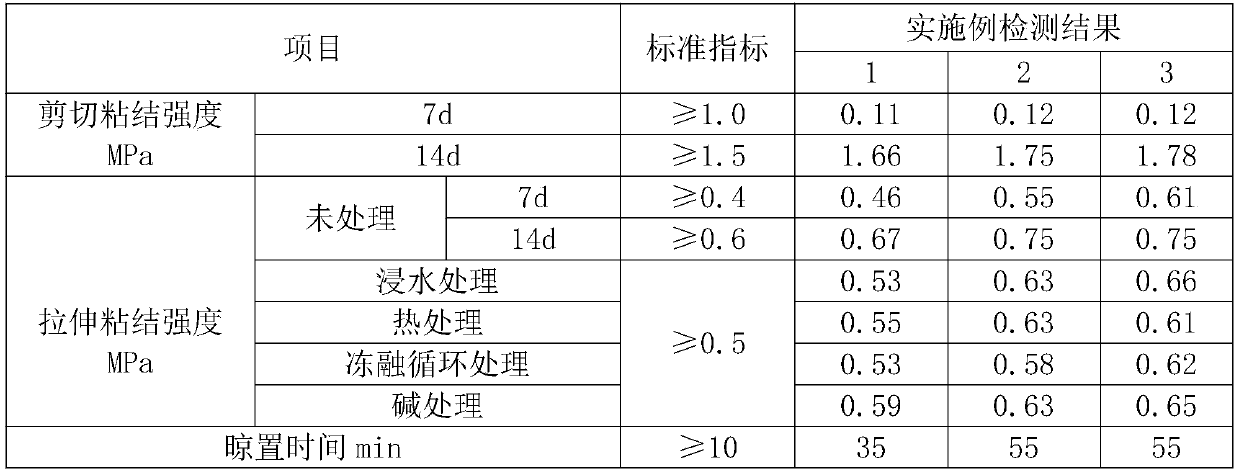

Examples

Embodiment Construction

[0018] An interface agent for mechanized construction, which consists of the following components in terms of mass percentage: 0-15% of machine-made sand, 45% of cement, 37%-52% of powder, and the balance is additives. The particle size of the machine-made sand is Between 0-1.2mm. The machine-made sand is made by crushing high-purity limestone, the sand fineness modulus is controlled between 2.4-2.5, the powder content below 0.075mm is not more than 12%, and the mud content is not more than 3%. The additives are 0.01% of hydroxypropyl methylcellulose ether, 2.48% of redispersible latex powder, 0.01% of starch ether, 0.1% of wood fiber, 0.2% of thixotropic lubricant and 0.2% of defoamer. The cement is P.042.5R ordinary Portland cement. The powder is not less than 80% of the particles with a particle size below 0.075 mm produced during the crushing process of machine-made sand, the fineness modulus (0.045 μm of the screen) is not more than 20%, and the water demand ratio is not...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com