Method for producing efficient compound fertilizer from leather wastewater through efficient denitrification

A compound fertilizer and high-efficiency technology, applied in magnesium fertilizers, inorganic fertilizers, fertilization devices, etc., can solve the problems of less reagent addition, secondary pollution, inability to effectively remove ammonia nitrogen, etc., and achieve the effect of improving mineralization capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

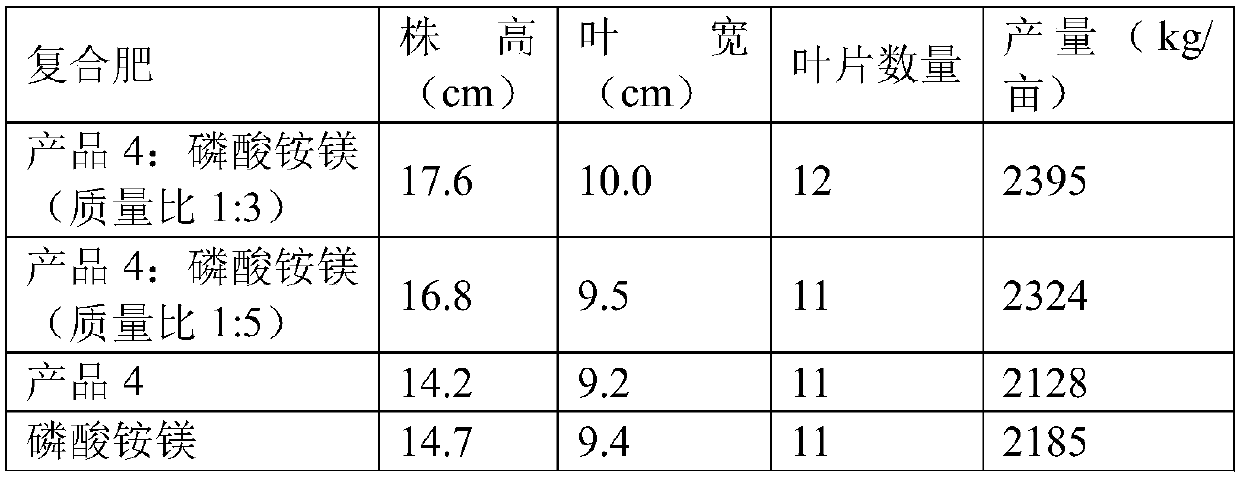

Examples

Embodiment 1

[0024] (1) Dissolve dry yeast powder (100g) and glucose (200g) in deionized water (10L), culture at 30°C for 1.0h, centrifuge and wash with deionized water to obtain yeast;

[0025] (2) Add MgCl to the yeast obtained in step (1) 2 solution (10L, 1mol / L) and H 3 PO 4 Solution (10L, 1mol / L), stirred at room temperature for 0.5h, then heated to 180°C, reacted for 5h, centrifuged, washed with deionized water, dried, and ground to obtain the precursor;

[0026] (3) Put the precursor obtained in step (2) in a tube furnace, under the protection of nitrogen, increase the temperature to 800°C at a rate of 10°C / min and calcined for 4 hours, and then return to room temperature to obtain the supported A biocarbon material of magnesium and phosphate ions (hereinafter referred to as Product A).

Embodiment 2

[0028] (1) Dissolve dry yeast powder (100g) and glucose (200g) in deionized water (10L), culture at 35°C for 0.5h, centrifuge and wash with deionized water to obtain yeast;

[0029] (2) Add MgCl to the yeast obtained in step (1) 2 solution (10L, 1mol / L) and H 3 PO 4 Solution (10L, 1mol / L), at room temperature, after stirring for 0.5h, warm up to 170°C, react for 8h, centrifuge, wash with deionized water, dry, and grind to obtain the precursor;

[0030] (3) Put the precursor obtained in step (2) in a tube furnace, under the protection of nitrogen, increase the temperature to 800°C at a rate of 10°C / min and calcined for 4 hours, and then return to room temperature to obtain the supported A biocarbon material of magnesium and phosphate ions (hereinafter referred to as product B).

Embodiment 3

[0032] (1) Dissolve dry yeast powder (100g) and glucose (200g) in deionized water (10L), culture at 30°C for 1.0h, centrifuge and wash with deionized water to obtain yeast;

[0033] (2) Add MgCl to the yeast obtained in step (1) 2 solution (10L, 0.1mol / L) and H 3 PO 4 Solution (10L, 0.1mol / L), stirred at room temperature for 0.5h, then heated up to 180°C, reacted for 5h, centrifuged, washed with deionized water, dried, and ground to obtain the precursor;

[0034] (3) Place the precursor obtained in step (2) in a tube furnace, and under the protection of nitrogen, raise the temperature to 800°C at a rate of 10°C / min and calcinate for 4 hours, and then return to room temperature to obtain loaded magnesium and Phosphate ion bio-carbon material (hereinafter referred to as product C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com