Fermentation culture medium for 2-keto-L-gulonic acid and fermentation production method of 2-keto-L-gulonic acid

A fermentation medium and production method technology, applied in microorganism-based methods, biochemical equipment and methods, fermentation and other directions, can solve problems such as affecting yield, and achieve the effects of improving synthesis efficiency, promoting growth and metabolism, and shortening fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

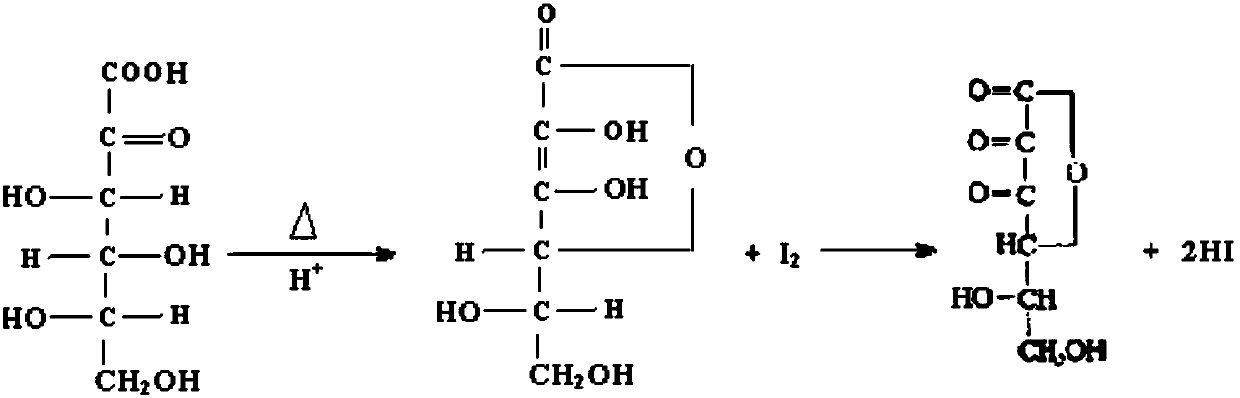

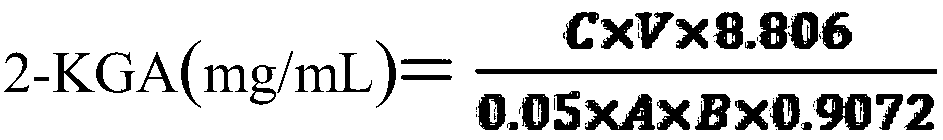

Image

Examples

preparation example Construction

[0048] (2) Preparation of culture medium

[0049] The following medium components all use materials commonly used in the art, and the preparation method is also a preparation method known in the art. The composition of each medium is as follows:

[0050] 1). Solid medium (g / L): L-sorbose 60~80, corn steep liquor 4.0~6.0, urea 11.0~13.0, potassium dihydrogen phosphate 0.5~1.5, anhydrous magnesium sulfate 0.1~0.2, calcium carbonate 4.0 ~6.0, mixed nutrients 0.007~0.009, agar 15~20, pH 6.0~8.0.

[0051] 2). Liquid medium (g / L): L-sorbose 80~120, corn steep liquor 4.0~6.0, urea 11.0~13.0, potassium dihydrogen phosphate 0.5~1.5, anhydrous magnesium sulfate 0.1~0.2, calcium carbonate 4.0 ~6.0, mixed nutrition 0.007~0.009, pH6.0~8.0.

[0052] 3). Fermentation medium (g / L): L-sorbose 80~120, corn steep liquor 4.0~6.0, urea 11.0~13.0, potassium dihydrogen phosphate 0.5~1.5, anhydrous magnesium sulfate 0.1~0.2, calcium carbonate 4.0 ~6.0, mixed nutrition 0.007~0.009, pH6.0~8.0.

[0...

Embodiment 1

[0081] 1) Prepare a mixed nutrient, which consists of 33% cytochrome C and 67% hemoglobin in weight percent. After the preparation is completed, filter and sterilize in an ultra-clean workbench for later use.

[0082] 2) Preparation of fermentation medium (g / L): L-sorbose 120.0, corn steep liquor 5.0, urea 12.0, potassium dihydrogen phosphate 1.0, anhydrous magnesium sulfate 0.1, calcium carbonate 5.0, mixed nutrient 0.008, adjust pH 7.0 , sterilized at 115°C for 25 minutes, in which sorbose was sterilized at 115°C for 25 minutes alone.

[0083] 3) Inoculate the seed solution of the expanded culture in the fermentation medium with a 20% inoculation amount, and use a 15L fermenter for fermentation (70% liquid volume), temperature 32°C, pH 6.8, stirring speed 600rpm, ventilation rate 15L / min, tank pressure 0.03MPa under the conditions of fermentation, synthesis of 2-KGA. In the middle and late stages of fermentation, when the concentration of the mixed nutrient drops to 0.002...

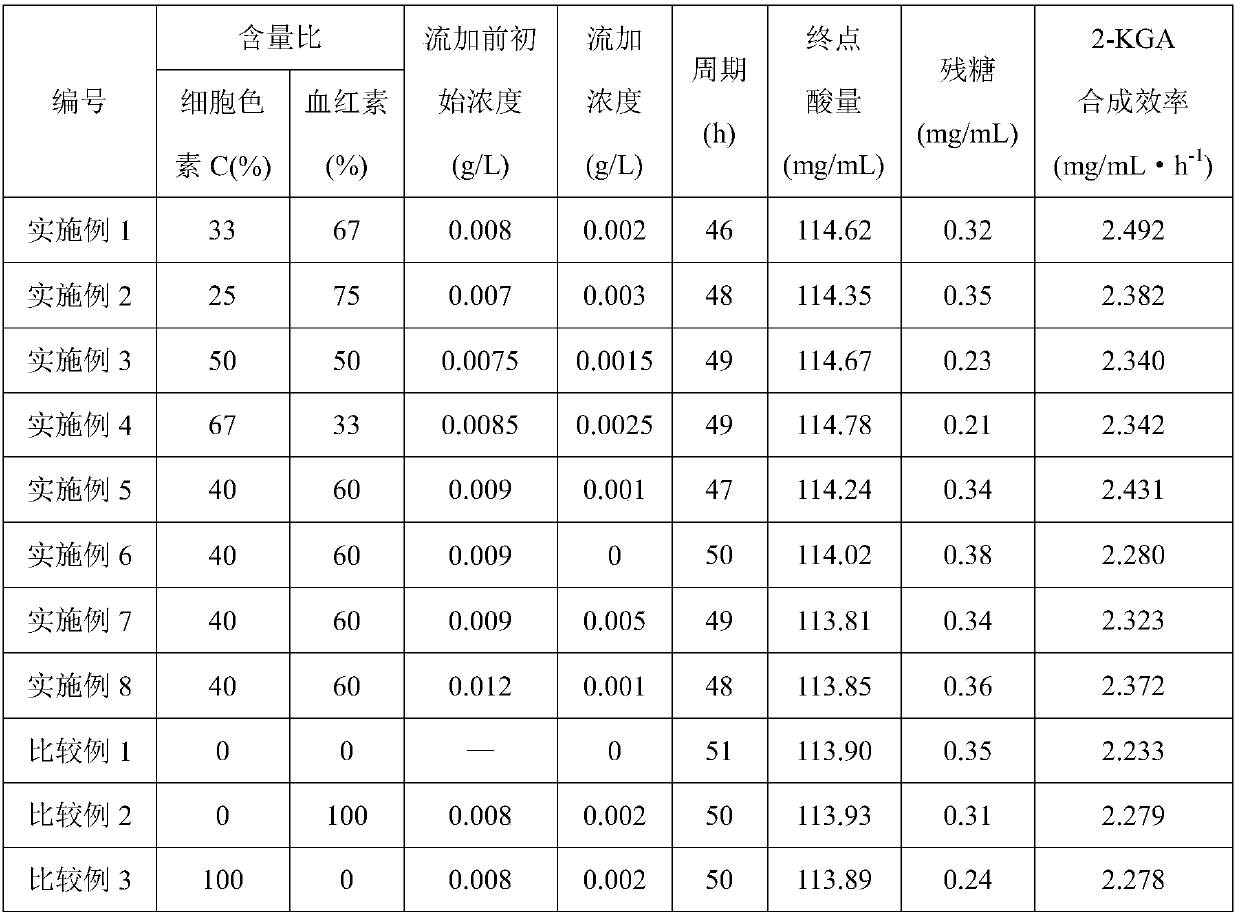

Embodiment 2~8 and comparative example 1~3

[0085] According to the method of Example 1, parameters such as the content of cytochrome C and hemoglobin in the mixed nutrient, the initial concentration of the mixed nutrient, and the feeding concentration of the mixed nutrient were adjusted. Other conditions were the same as in Example 1, and the results were as follows 1 shows:

[0086] Table 1

[0087]

[0088] As can be seen from the data in Table 1, no cytochrome and / or heme was added to the culture medium of Comparative Examples 1-3, compared with it, the fermentation cycle of Examples 1-8 with cytochrome and / or heme added was short And the synthesis efficiency of 2-KGA is high.

[0089] Among them, in the medium of Examples 1-5, not only cytochrome C with a content in the range of 25-67% and heme with a content in the range of 33-75% were added, but also the mixed nutrients in the fermentation medium before inoculation The concentration of the cytochrome is kept in the range of 0.007~0.009g / L, and in the middle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com