Morphology genetic derivative composite material, preparation method and application thereof

A composite material and state-of-the-art technology, applied in the field of electrocatalytic materials, can solve the problems of preparing electrocatalytic materials, and achieve the effect of economical preparation method and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

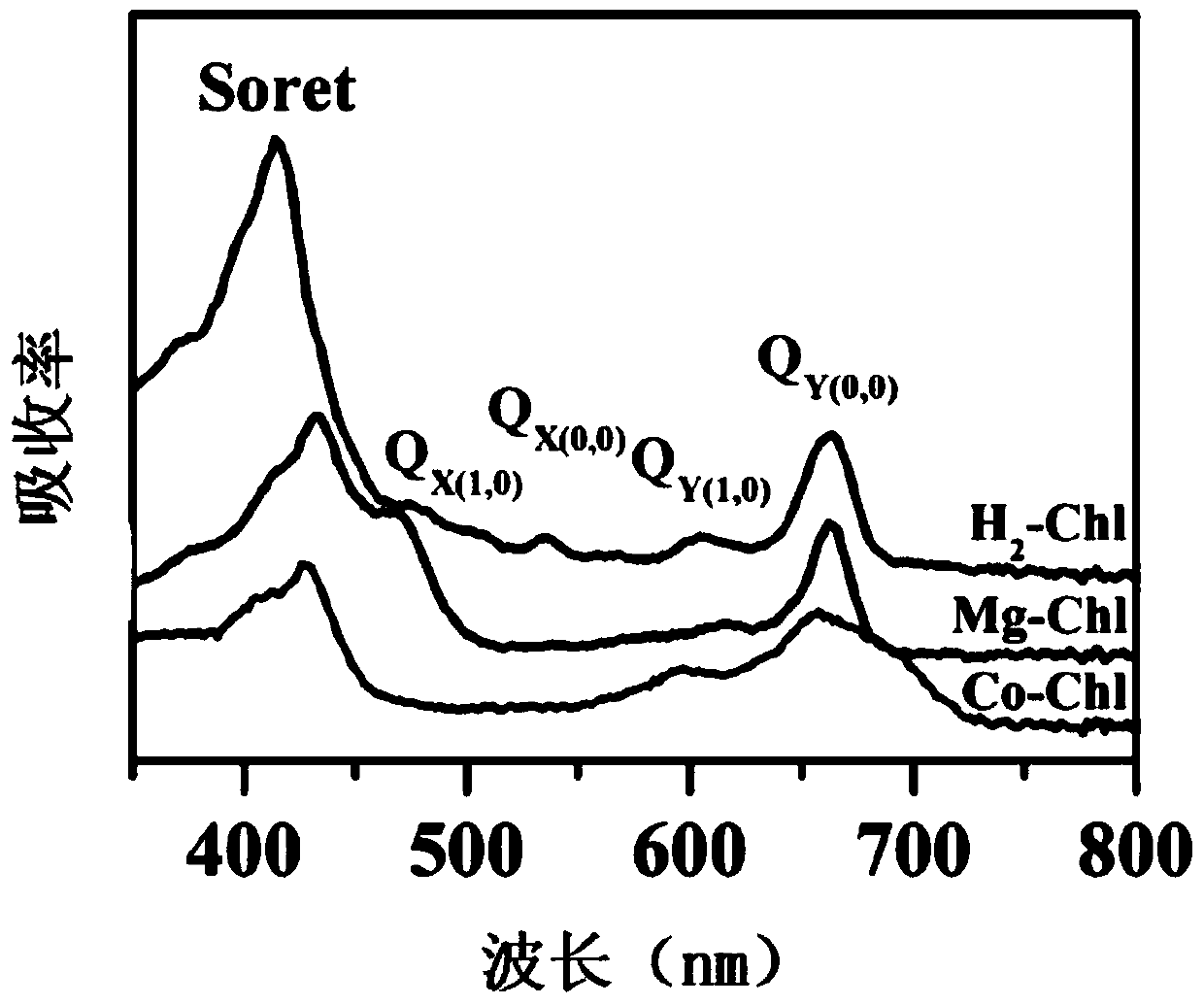

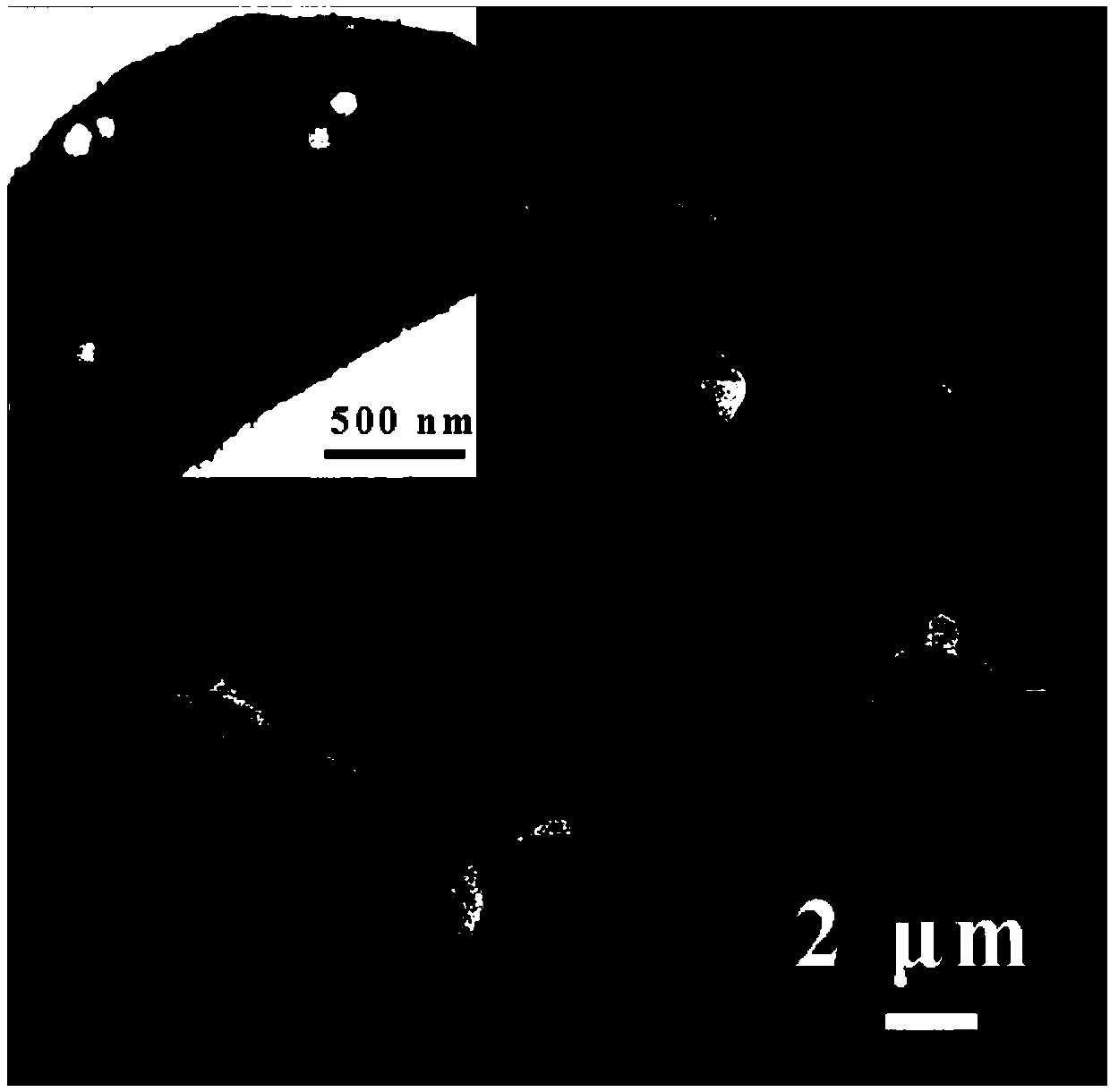

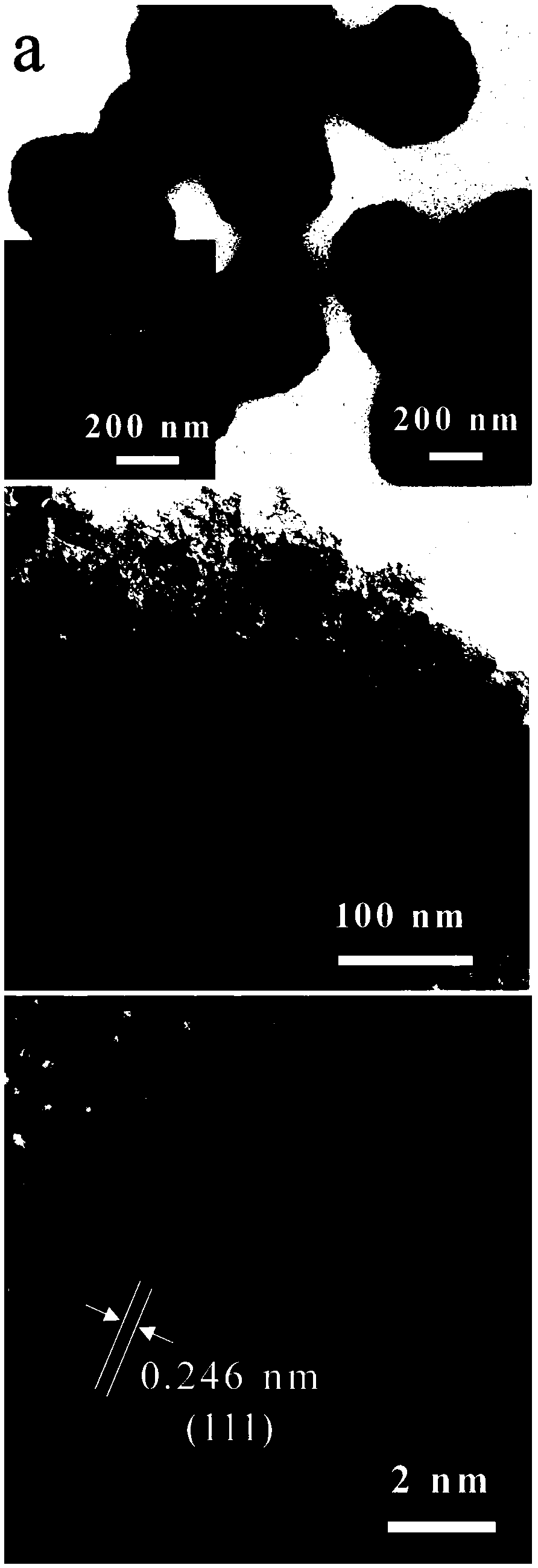

[0039] Co-N-C / CoO x A method for preparing a composite material derived from a relic, comprising the following steps:

[0040](1) Extract natural chloroplasts with spinach leaves as raw material: the leaves are broken, and the broken leaves are placed in an extract solution (0.4mol / L sucrose+0.05mol / L Tris-HCl[pH=7.6]+0.01mol / L NaCl (prepared with deionized water) in a mortar (add 20-30ml extract per 10g of leaves), quickly grind for 2-5min; filter the obtained green pasty substance with 3-5 layers of gauze, and get the filtrate; Centrifuge at 300×g for 3 minutes to remove mesophyll cell walls, residues, etc. Take the organelle-rich supernatant, then centrifuge at 1000×g for 5 minutes to remove the supernatant containing other organelles, and take the green sediment at the bottom of the centrifuge tube (chloroplast) and add the extract to suspend the chloroplast, repeat the above differential centrifugation process 3 times to obtain the purified chloroplast; finally, soak the...

Embodiment 2

[0046] Cu-N-C / CuO x A method for preparing a composite material derived from a relic, comprising the following steps:

[0047] (1) Extract natural chloroplasts with spinach leaves as raw material: the leaves are broken, and the broken leaves are placed in an extract solution (0.4mol / L sucrose+0.05mol / L Tris-HCl[pH=7.6]+0.01mol / L NaCl (prepared with deionized water) in a mortar (add 20-30ml extract per 10g of leaves), quickly grind for 2-5min; filter the obtained green pasty substance with 3-5 layers of gauze, and get the filtrate; Centrifuge at 300×g for 3 minutes, take the supernatant, then centrifuge at 1000×g for 5 minutes, remove the supernatant, take the green sediment (chloroplast) at the bottom of the centrifuge tube and add the extract to suspend the chloroplast, repeat the above differential centrifugation Process 3 times to obtain purified chloroplasts; finally, soak the purified chloroplasts in 2.5wt% glutaraldehyde phosphate buffer solution [pH=7.2] for 12-24 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com