Additive manufacturing technology-based pure titanium or titanium alloy surface micro/nano structure constructing method and application

A technology of additive manufacturing and construction methods, applied in cleaning methods and utensils, cleaning methods using liquids, additive manufacturing, etc., can solve problems such as unsuitable complex structures and poor adhesion of film layers, and achieve stable and controllable micro-nano structures , strong adaptability and superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0047] The pure titanium bulk material is formed by selective laser melting, and the micro-nano structure is constructed on the surface of pure titanium by hydrothermal treatment.

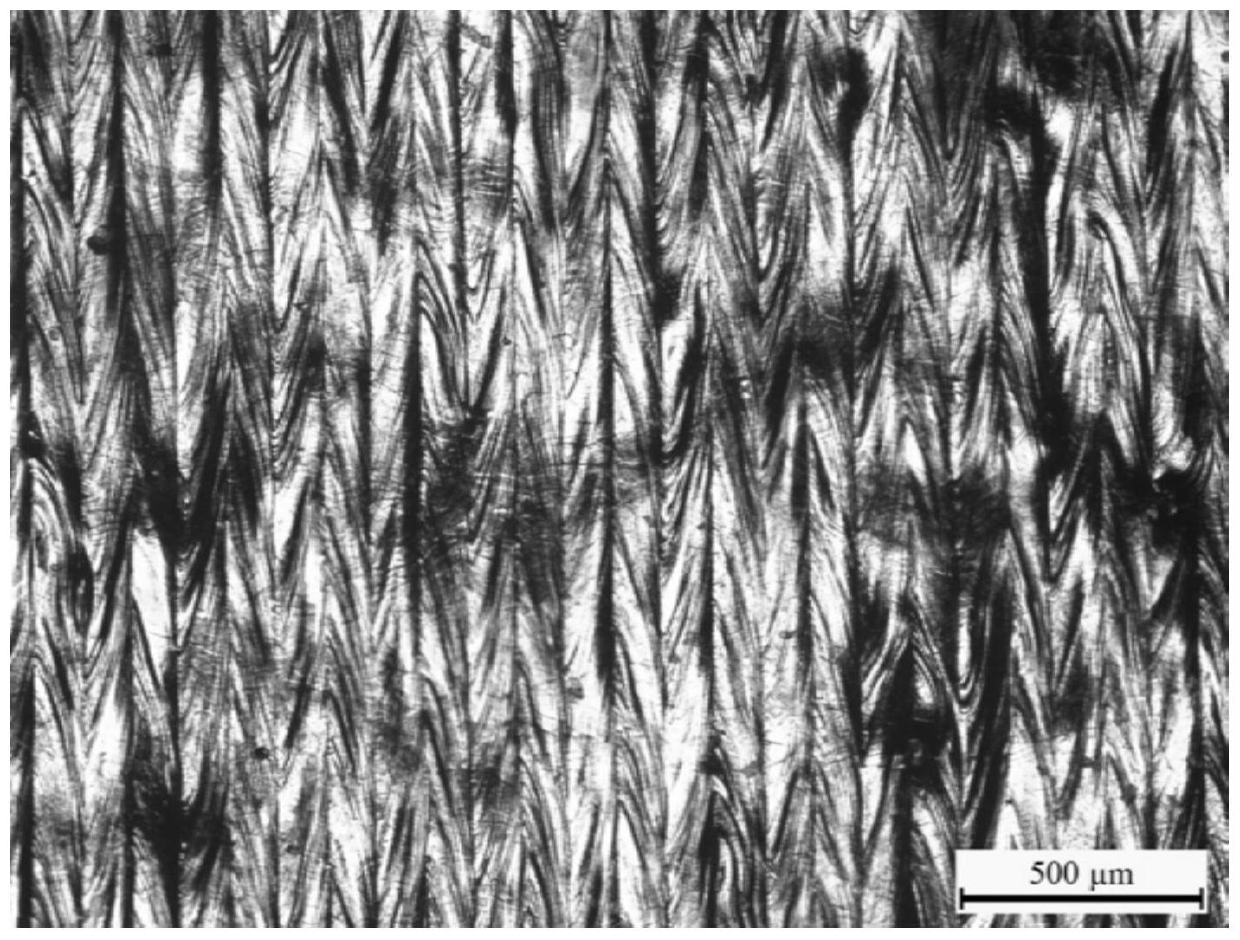

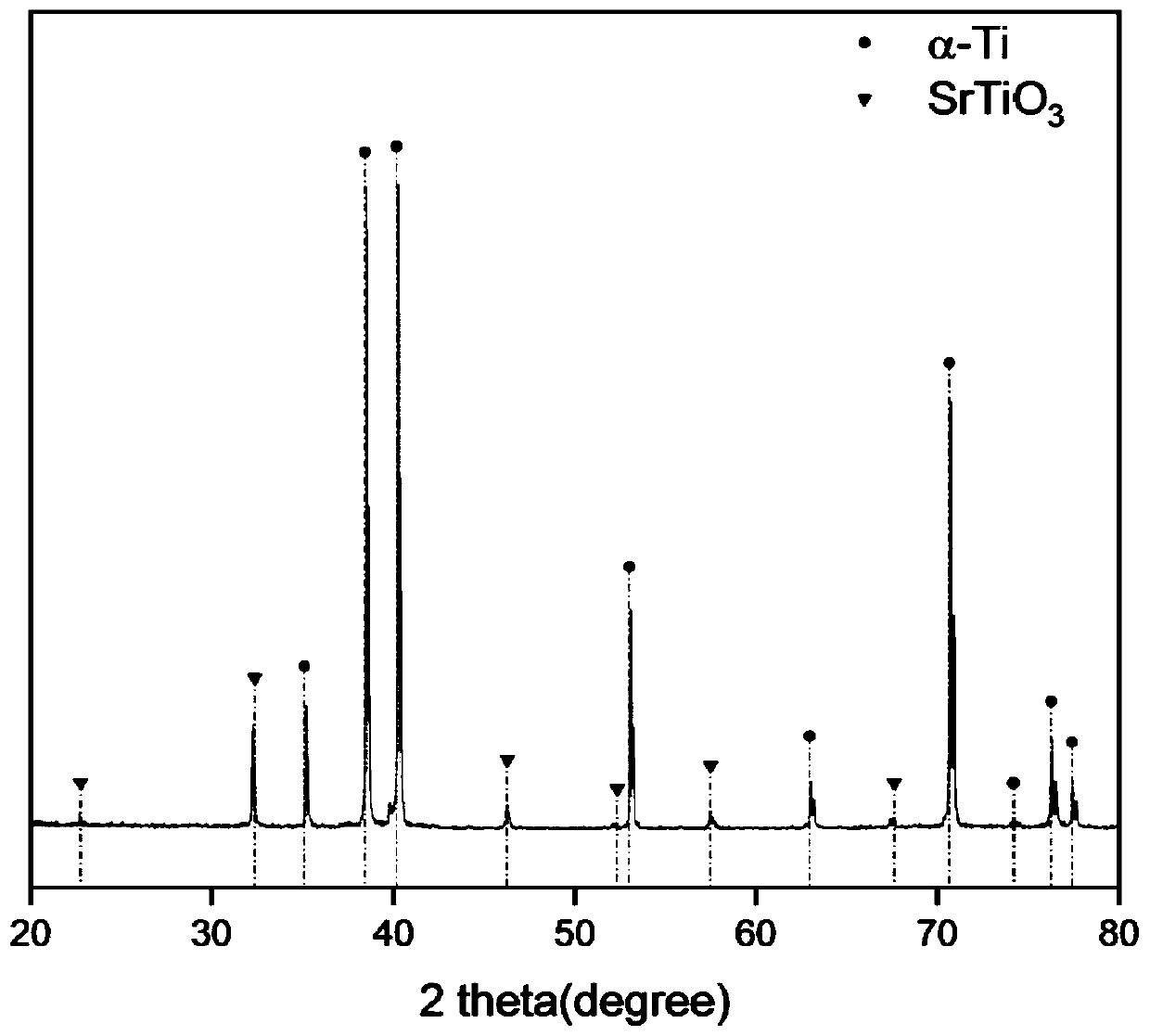

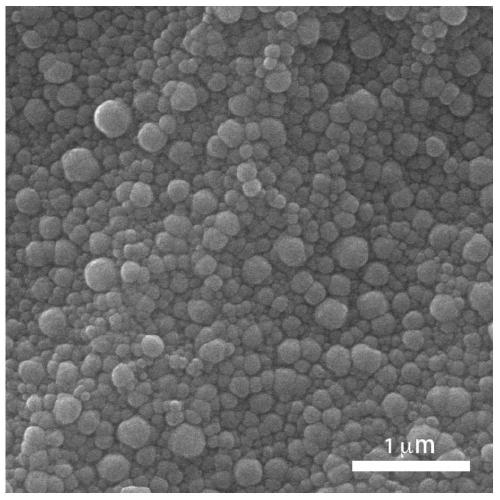

[0048] A 14×14×3mm pure titanium block material is prepared by selective laser melting technology, and the laser directly acts on the front side. The particle size of the powder taken is 20-60 μm, the laser power is 400W, the powder coating thickness is 0.04mm, the laser scanning distance is 0.09mm, and the laser scanning speed is 1700mm / s. The pure titanium block was cut into 7×7×3mm by wire cutting, ultrasonically cleaned with acetone, ethanol and deionized water in sequence, 10min each time, and dried in a vacuum oven at 50°C. Prepare 0.1mol / L strontium chloride solution as liquid A, configure 1mol / L NaOH solution as liquid B, and mix liquids A and B uniformly in the same volume as liquid mixture. Put the sample face up, place it in a 100ml polytetrafluoroethylene hydrothermal reactor liner fil...

Embodiment example 2

[0052] The pure titanium bulk material is formed by selective laser melting, and the micro-nano structure is constructed on the surface of pure titanium by hydrothermal treatment.

[0053] A 14×14×3mm pure titanium block material is prepared by selective laser melting technology, and the laser directly acts on the front side. The particle size of the powder taken is 20-60 μm, the laser power is 400W, the powder coating thickness is 0.04mm, the laser scanning distance is 0.09mm, and the laser scanning speed is 1700mm / s. The pure titanium block was cut into 7×7×3mm by wire cutting, ultrasonically cleaned with acetone, ethanol and deionized water in sequence, 10min each time, and dried in a vacuum oven at 50°C. Put the sample face up, place it in a 100ml polytetrafluoroethylene hydrothermal reactor liner filled with 30ml 1mol / L NaOH solution, and react at 200°C for 16h. Then take it out and ultrasonically clean it twice with deionized water, 10min each time. Subsequently, ion e...

Embodiment example 3

[0057] The pure titanium bulk material is formed by selective laser melting, and the micro-nano structure is constructed on the surface of pure titanium by hydrothermal treatment.

[0058] A 14×14×3mm pure titanium block material is prepared by selective laser melting technology, and the laser directly acts on the front side. The particle size of the powder taken is 20-60 μm, the laser power is 400W, the powder coating thickness is 0.04mm, the laser scanning distance is 0.09mm, and the laser scanning speed is 1700mm / s. The pure titanium block was cut into 7×7×3mm by wire cutting, ultrasonically cleaned with acetone, ethanol and deionized water in sequence, 10min each time, and dried in a vacuum oven at 50°C. Place the sample face up, place it in a 100ml polytetrafluoroethylene hydrothermal reactor liner filled with 60ml 0.5mol / L NaOH solution, and react at 200°C for 16h. Then take it out and ultrasonically clean it twice with deionized water, 10min each time. Subsequently, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com