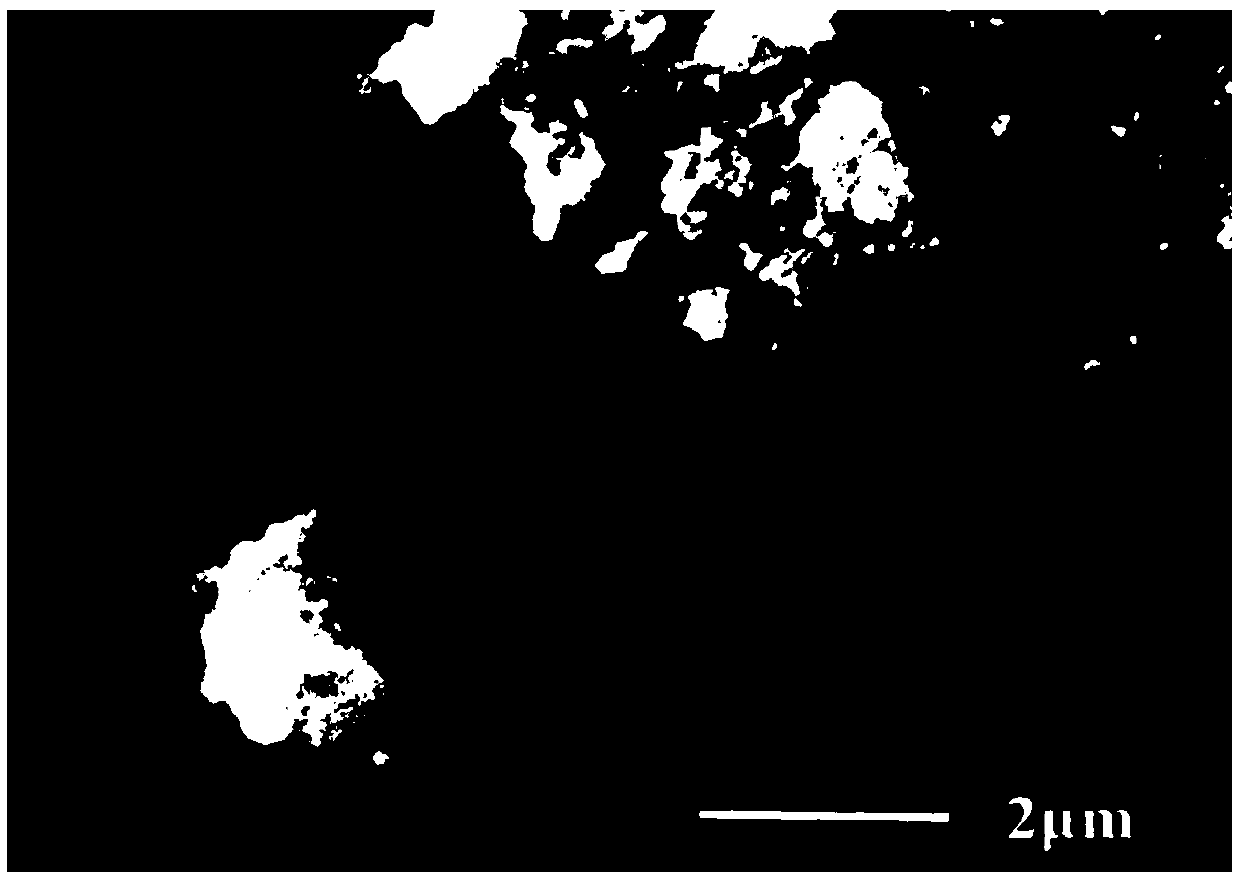

Preparation method of heat-insulating TiO2/SiO2 composite aerogel material

A composite airgel and thermal insulation technology, which is applied in the direction of airgel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problems of ineffective acquisition, reduction of microstructure, thermal insulation, etc., and achieve high surface energy, Excellent infrared light shielding function, large specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a thermal insulation type TiO 2 / SiO 2 The preparation method of composite airgel material, concrete steps are as follows:

[0051] (1) Preparation of SiO 2 sol

[0052] The first step is to mix methyl orthosilicate, methanol, an insufficient amount of water, and an appropriate amount of hydrochloric acid. The mixed solution is refluxed at 82°C for 15 hours to achieve thorough mixing and increase the rate of hydrolysis, and then distilled at 90°C for 3 hours to remove the reaction. The generated methanol obtains partially hydrolyzed, partially polycondensed silica sol (CS); wherein the molar ratio of methyl orthosilicate, methanol, deionized water, and hydrochloric acid is 0.6:1:0.1:1×10 -5 . The second step reaction is based on the required SiO 2 Density of the airgel Mix CS with a certain amount of non-alcoholic organic solvent acetonitrile, water, and ammonia water at a volume ratio of 1:5:1.1:0.02. After sufficient hydrolysis (the temp...

Embodiment 2

[0061] This embodiment provides a thermal insulation type TiO 2 / SiO 2 The preparation method of composite airgel material, concrete steps are as follows:

[0062] (1) Preparation of SiO 2 sol

[0063] The first step is to mix tetraethyl orthosilicate, ethanol, an insufficient amount of water and an appropriate amount of hydrochloric acid. The mixed solution is refluxed at 85°C for 17 hours to achieve full mixing and increase the hydrolysis rate, and then distilled at 92°C for 4 hours to remove The ethanol generated by the reaction obtains partially hydrolyzed and partially polycondensed silica sol (CS); wherein the molar ratio of tetraethylorthosilicate, ethanol, deionized water, and hydrochloric acid is 0.7:10:0.8:2×10 -5 . The second step reaction is based on the required SiO 2 Density of the airgel Mix CS with a certain amount of non-alcoholic organic solvent acetonitrile, water, and ammonia water at a volume ratio of 1:15:1.3:0.024. After sufficient hydrolysis (the ...

Embodiment 3

[0072] This embodiment provides a thermal insulation type TiO 2 / SiO 2 The preparation method of composite airgel material, concrete steps are as follows:

[0073] (1) Preparation of SiO 2 sol

[0074] The first step is to mix tetraethyl orthosilicate, isopropanol, an insufficient amount of water and an appropriate amount of hydrochloric acid. The mixed solution is refluxed at 86°C for 18 hours to achieve full mixing and increase the hydrolysis rate, and then distilled at 93°C for 4 Remove the ethanol generated by the reaction in one hour to obtain partially hydrolyzed, partially polycondensed silica sol (CS); wherein the mol ratio of tetraethylorthosilicate, isopropanol, deionized water, and hydrochloric acid is 0.9:15:1.2:4× 10 -5 . The second step reaction is based on the required SiO 2 Density of the airgel Mix CS with a certain amount of non-alcoholic organic solvent acetonitrile, water, and ammonia water at a volume ratio of 1:25:1.4:0.026. After sufficient hydrol...

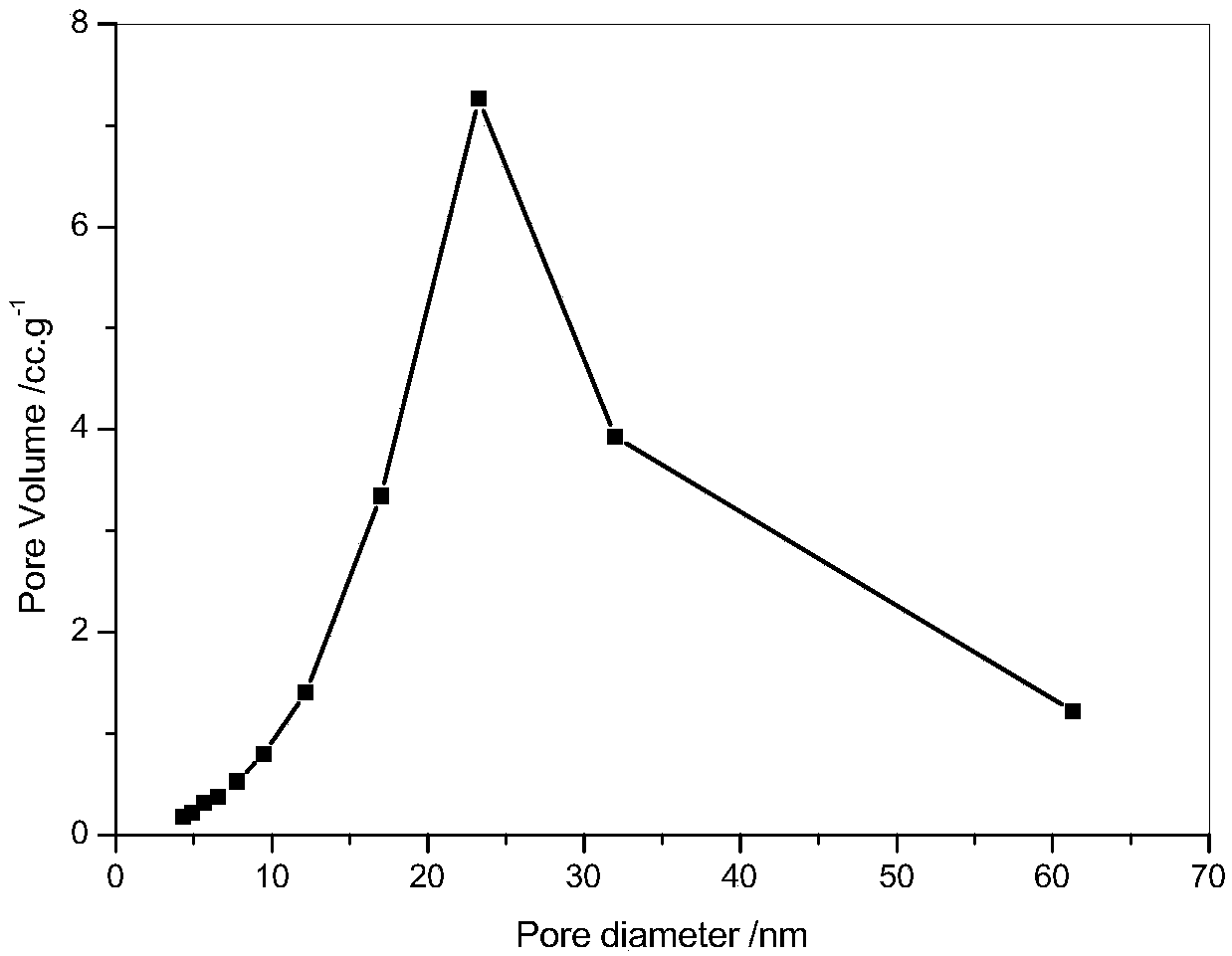

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com