Method for preparing soil heavy metal solidification material by using oil shale semi-coke

A technology for oil shale semi-coke and solidified materials, applied in the field of waste resource reuse, can solve the problems of low added value, limited utilization, environmental pollution, etc., and achieve good ecological and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

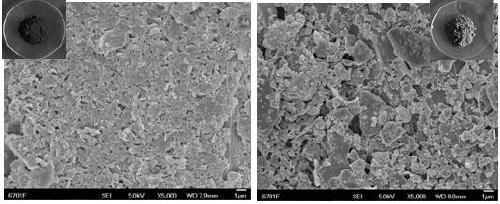

Image

Examples

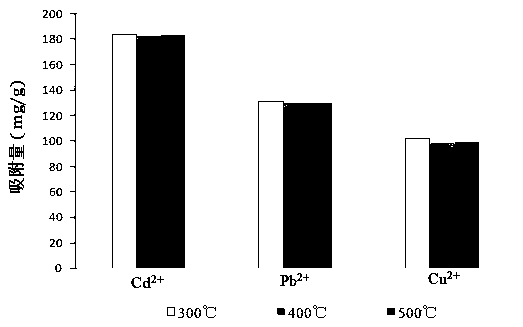

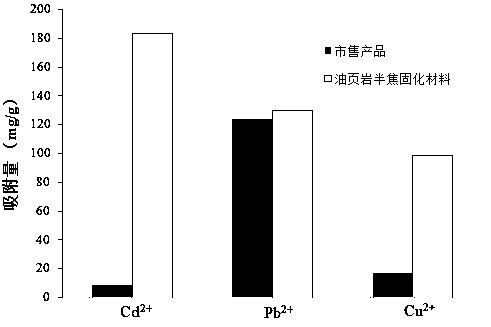

Embodiment 1

[0021] The crushed oil shale semi-coke was subjected to wet grinding under the condition of solid-liquid mass ratio of 1:10, passed through a 200-mesh sieve, and then activated by adding 10% sulfuric acid (concentration: 5%) of semi-coke mass for 3 hours, and then used Plate-and-frame filter press dehydration until the moisture content of the filter cake is less than 50%, then send it into the rotary kiln with twin-screws, and calcine at 300°C for 1 hour under a nitrogen atmosphere, crush and sieve to obtain the product. The cured material is Cd 2+ , Pb 2+ and Cu 2+ The adsorption capacity of these materials reaches about 180mg / g, 130mg / g and 100mg / g respectively.

Embodiment 2

[0023] The crushed oil shale semi-coke was subjected to wet grinding under the condition of solid-liquid mass ratio of 1:10, passed through a 200-mesh sieve, and activated by adding sulfuric acid (concentration 3%) with 8% mass of semi-coke for 2 hours, and then used Plate-and-frame filter press dehydration until the moisture content of the filter cake is less than 50%, sent to the rotary kiln with twin-screws, calcined at 400°C for 2 hours in a nitrogen atmosphere, crushed, and sieved to obtain the product. The cured material is Cd 2+ , Pb 2+ and Cu 2+ The adsorption capacity of these materials reaches about 183mg / g, 99mg / g and 130mg / g respectively.

Embodiment 3

[0025] The crushed oil shale semi-coke was wet ground under the condition of solid-liquid mass ratio of 1:15, passed through a 200-mesh sieve; 3% sulfuric acid (concentration: 10%) by mass of the semi-coke was added for acid activation treatment for 3 hours, and then used Plate-and-frame filter press dehydration until the moisture content of the filter cake is less than 50%, sent to the rotary kiln with twin screws, calcined at 500°C for 3 hours in a nitrogen atmosphere, crushed, and sieved to obtain the product. The cured material is Cd 2+ , Pb 2+ and Cu 2+ The adsorption capacity of these materials reaches about 160mg / g, 120mg / g and 110mg / g respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com