A Method for Preventing the Formation of Miscellaneous Crystal Defects in Single Crystal Superalloy Rotating Blades

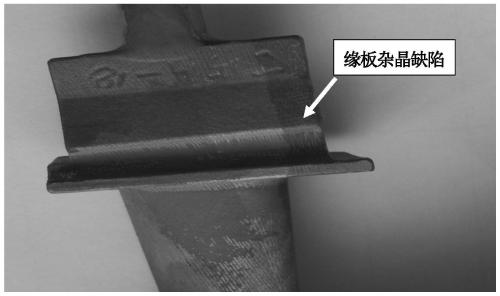

A high-temperature alloy and rotating blade technology, which is applied in the field of high-temperature alloy single crystal blade preparation, can solve problems such as defects and small-angle grain boundaries on the edge plate, and achieve low cost, reduce the formation of miscellaneous crystal defects, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this embodiment, nickel-based single crystal superalloy AM3 is used, and the composition of the alloy is shown in Table 1.

[0034] Table 1 Alloying element weight percent

[0035] Cr Mo Al W Ti Ta co Ni 8.0 2.0 5.6 5.0 1.0 4.0 6.0 Remain

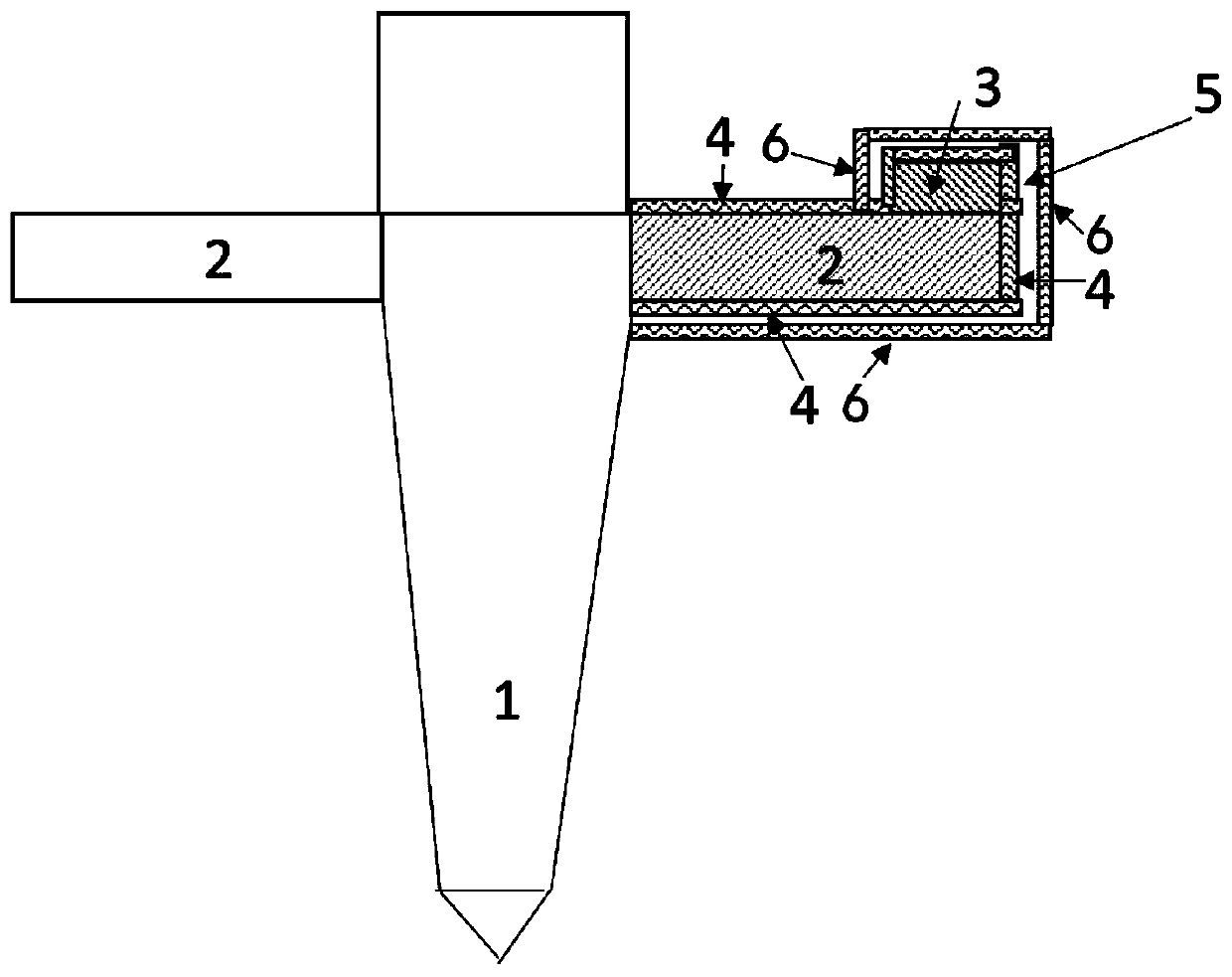

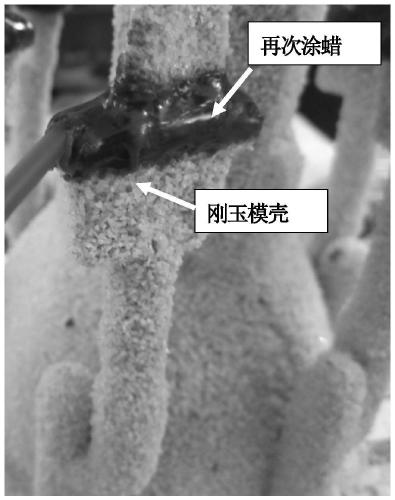

[0036] In this embodiment, a single crystal blade for an engine is taken as an example. The size of the single side edge plate of the single crystal blade is about 15 mm long x 10 mm wide x 2 mm thick. The alloy turns the temperature field at the edge of the blade, thereby reducing the formation of edge plate stray grain defects. Melt the paraffin at 50°C, inject the molten paraffin into the pre-designed single crystal blade metal mold with a thermal insulation riser through a wax injection machine, wherein the thermal insulation riser is 8mm long × 5mm wide × 0.5mm thick, and put Composition of the wax model Complete the combination of the wax model, dry the assembled wax model by hanging sl...

Embodiment 2

[0038] In this embodiment, nickel-based superalloy SRR99 is used, and the composition of the alloy is shown in Table 2.

[0039] Table 2 Weight percent of main alloying elements in SRR99 alloy

[0040] C Cr co Al Ti W Ta Nb Ni 0.05 9.0 6.0 5.5 1.0 9.5 3.0 1.0 Remain

[0041]This embodiment This embodiment takes a single crystal blade for an engine as an example. The size of the single side edge plate of the single crystal blade is about 35 mm in length x 15 mm in width x 5 mm in thickness. The temperature field at the edge plate of the rotating blade with superalloy crystals reduces the formation of stray grain defects on the edge plate. Melt the paraffin at 65°C, inject the molten paraffin into the pre-designed single crystal blade metal mold with a thermal insulation riser through a wax injection machine, wherein the thermal insulation riser is 12mm long x 8mm wide x 1mm thick and the wax mold Composition Completely assemble the wax p...

Embodiment 3

[0043] In this embodiment, a nickel-based superalloy René N5 is used, and the alloy composition is shown in Table 3.

[0044] Table 3 Weight percent of main alloying elements in René N5 alloy

[0045] Mo Cr co Al f W Ta Re Ni 2.0 7.0 8.0 6.2 0.15 5.0 7.0 3.0 Remain

[0046] This embodiment This embodiment takes the single crystal blade for an engine as an example. The size of the single side edge plate of the single crystal blade is about 85 mm long x 35 mm wide x 10 mm thick. The temperature field at the edge plate of the rotating blade with superalloy crystals reduces the formation of stray grain defects on the edge plate. Melt the paraffin at 80°C, inject the molten paraffin into the pre-designed single crystal blade metal mold with a thermal insulation riser through a wax injection machine, wherein the thermal insulation riser is 50mm long x 20mm wide x 10mm thick, and pour the wax The mold composition is to complete the combinatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com