Refining method of glycerin

A purification method and technology for glycerol, which are applied in chemical instruments and methods, separation/purification of hydroxyl compounds, alkali metal oxides/hydroxides, etc., can solve the problem of high energy consumption, high cost of purifying glycerol, and large amount of waste water, etc. problems, to achieve the effect of reducing production costs, simple and easy-to-obtain adsorbents, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

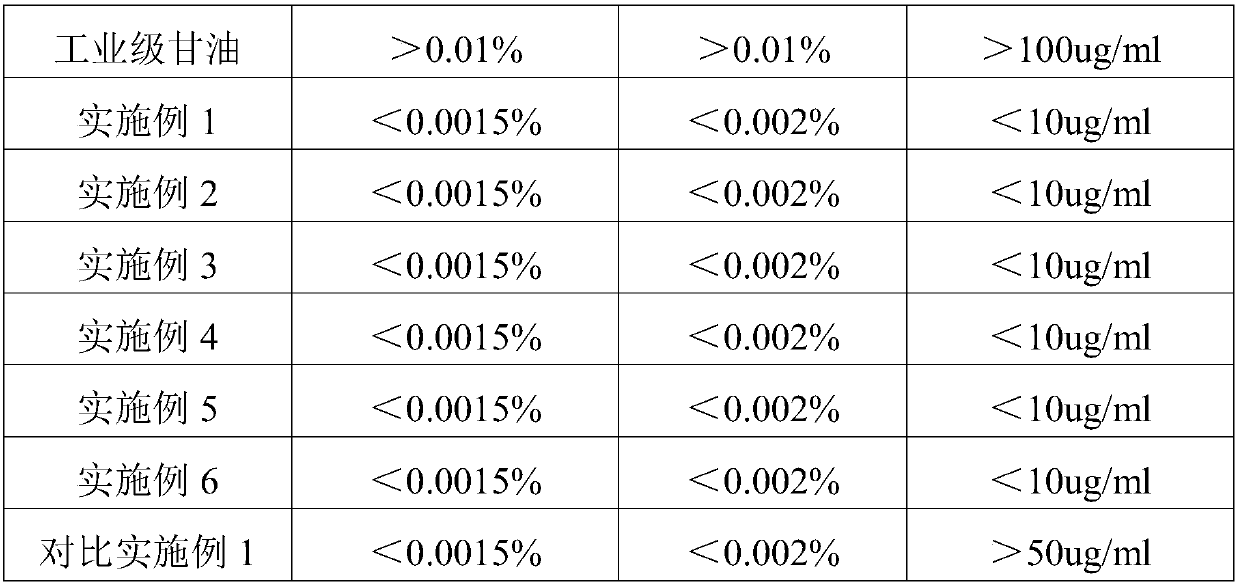

Embodiment 1

[0025] Preparation of calcium oxide-chitin fiber nanometer mesoporous particle spherical adsorbent: add chitin fiber into dilute calcium hydroxide aqueous solution, stir thoroughly, remove excess free acid, and filter to obtain alkalized chitin fiber. Add 1kg of food-grade calcium hydroxide and 5kg of alkalized chitin fiber to 5kg of distilled water, stir well to form a paste. A spherical pelletizer was used to form 2 mm calcium hydroxide-chitin fiber pellets into pellets. Dry the spheres at 150° C. for 5 hours to remove water and form calcium oxide-chitin fiber nanometer mesoporous spheres.

Embodiment 2

[0027] Preparation of composite adsorbent of decolorizing agent and filter aid: Physically mix 1 kg of medicinal activated carbon or medicinal activated clay with 1 kg of medicinal gypsum or medicinal diatomaceous earth, dry and activate at 120°C for 2 hours. Composite adsorbent for decolorizing agent and filter aid.

Embodiment 3

[0029] Add 3000 kg of industrial grade glycerin with a water content of 4 to 5% into a 5000L reactor, heat to 90°C, and keep the temperature for 2 hours. Cool down to 50°C, add 30 kg of the calcium oxide-chitin fiber nano-mesoporous particle ball adsorbent prepared in Example 1, adsorb for 50 minutes, and filter with a 200-mesh bag filter. Add 3 kg of the activated carbon / diatomite composite adsorbent prepared in Example 2 to the filtrate, adsorb for 2 hours at 60° C., and filter with a 400-mesh plate and frame filter to obtain pharmaceutical grade glycerin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com