Antifriction anti-wear composite material and preparation method thereof

A composite material, anti-friction and anti-wear technology, applied in the field of polymer materials, can solve problems such as low friction coefficient, achieve the effects of excellent performance, reduce loss, and increase tribological performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides an anti-friction and anti-wear composite material, which is formed by mixing ultra-high molecular weight polyethylene powder and sodium polyacrylate powder and then hot-pressed. The preparation method of the anti-friction and anti-wear composite material comprises the following steps:

[0027] Step 1. Select ultra-high molecular weight polyethylene powder, choose ultra-high molecular weight polyethylene powder as the base material, grind it fully, dry the ultra-high molecular weight polyethylene powder at 80°C for 2 hours, and remove the moisture of the ultra-high molecular weight polyethylene powder Finally, the powder that meets the requirements is obtained;

[0028] Step 2, matching electrolyte sodium polyacrylate powder;

[0029] Step 3, mechanical mixing, taking 1-5 parts of sodium polyacrylate powder and adding it to 100 parts of ultra-high molecular weight polyethylene powder, stirring and mixing evenly to form a mixed powder, drying the mi...

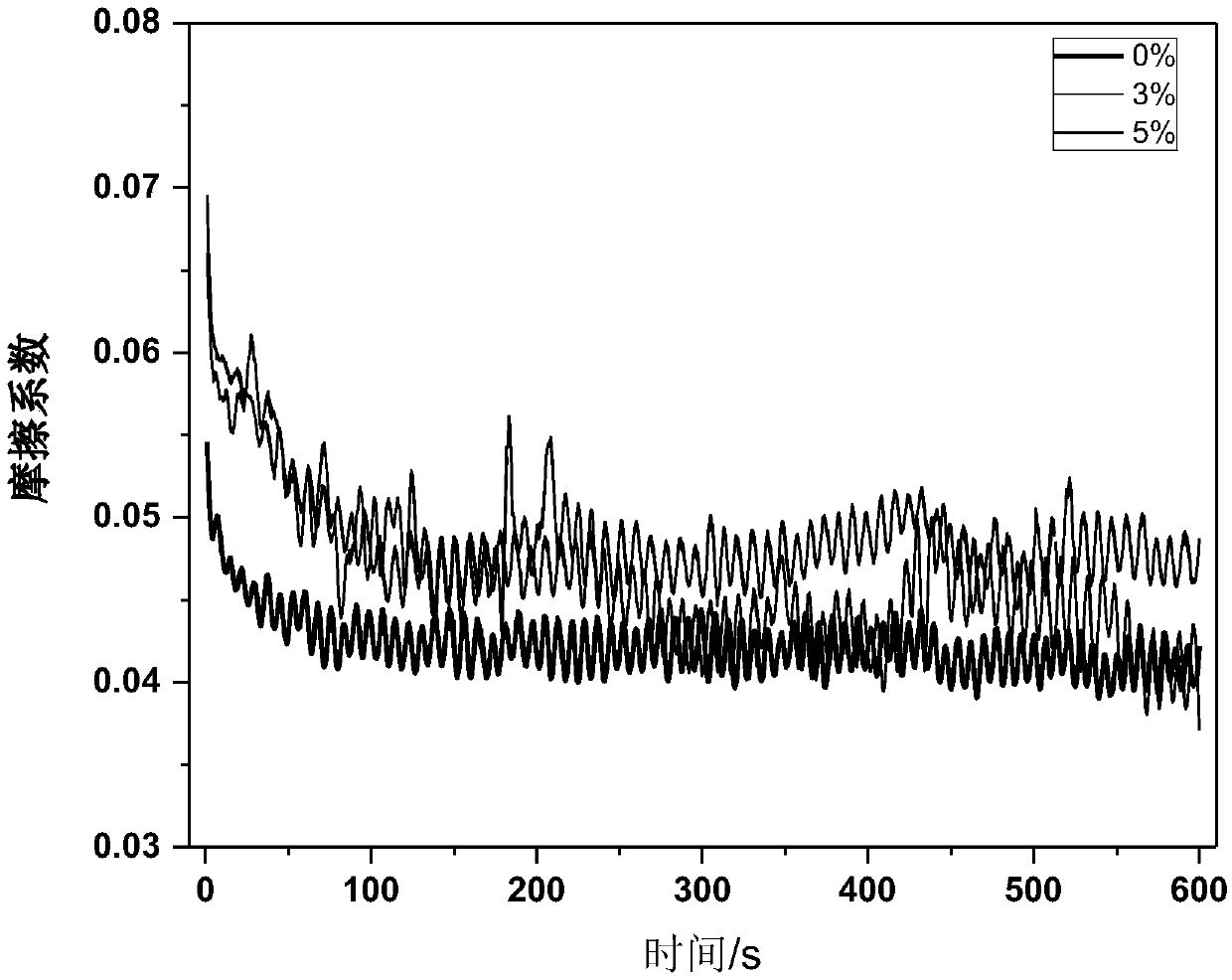

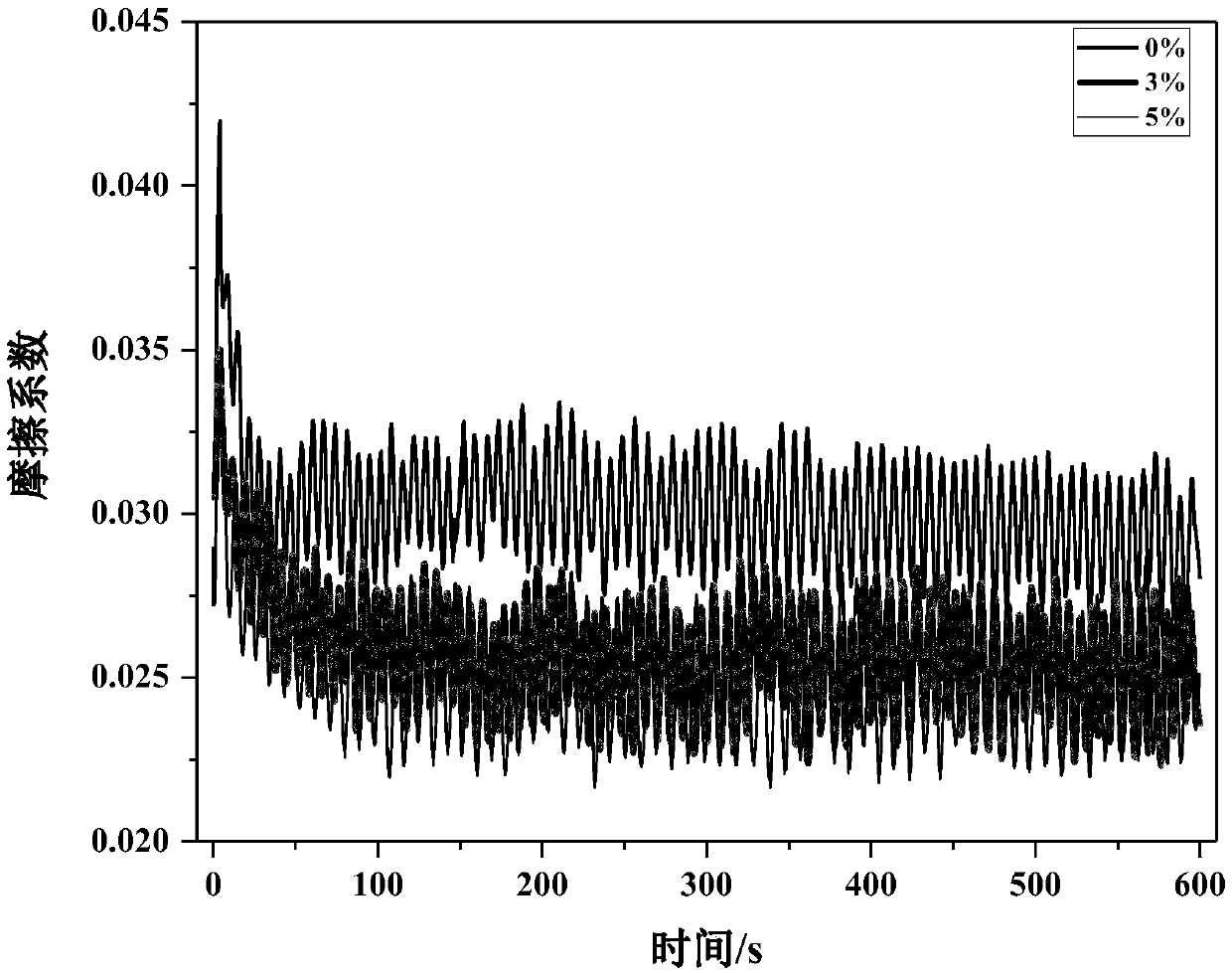

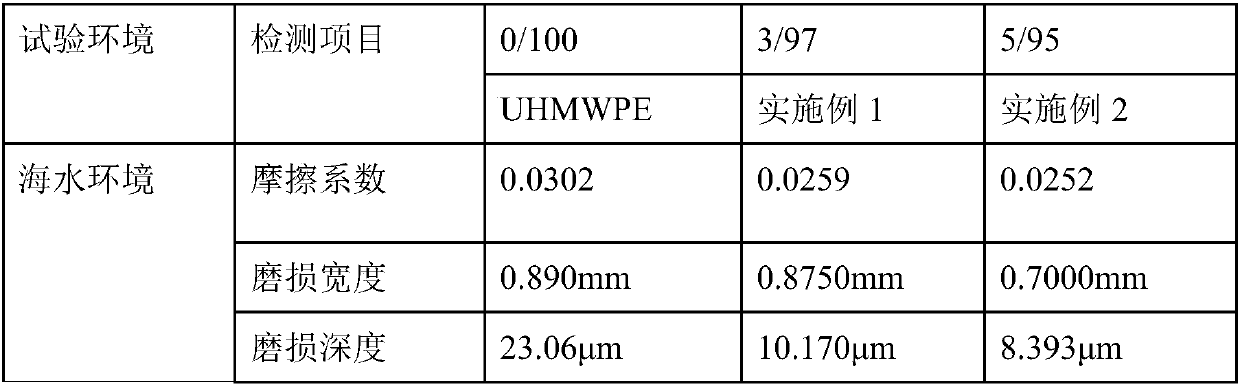

Embodiment 1

[0037] Example 1: Weigh the ultra-high molecular weight polyethylene (UHMWPE) powder with a total weight percentage of 97wt.%, grind it, and dry it in an oven at 70-100°C for 1-4h; weigh a total weight percentage of 3wt.% polyacrylic acid Sodium (PAANa), and then uniformly disperse the two by mechanical mixing, the mechanical mixing time is 45-60min; put the obtained UHMWPE / PAANa mixed powder in an oven at 70-100°C for 10-12h; take out the dried After mixing the powder, put it in the pre-cleaned mold, pre-press three times under the pressure of 30-40MPa, hold the pressure for 1-3min each time; unload the pressure after the pre-pressing process is completed; heat the mixed powder in the mold to 150- 200°C, keep warm for 1.5h; after the keep warm, gradually increase the pressure. When the temperature drops to 110°C, pressurize 10-20MPa; when the temperature drops to 100°C, pressurize 30-50MPa; when the temperature drops to 90°C, pressurize 70-90MPa; when the temperature drops to...

Embodiment 2

[0038]Embodiment 2: Weigh the ultra-high molecular weight polyethylene (UHMWPE) powder material that the total weight percentage is 95wt.%, grind, and dry in 70-100 ℃ oven for 1-4h; Weigh the polyacrylic acid that the weight percentage is 5wt.% Sodium (PAANa), and then uniformly disperse the two through mechanical mixing, and the mechanical mixing time is 45-60min; put the obtained UHMWPE / PAANa mixed powder in an oven at 70-100°C for 10-12h; take out the dried After mixing the powder, put it in the pre-cleaned mold, pre-press three times under the pressure of 30-40MPa, hold the pressure for 1-3min each time; unload the pressure after the pre-pressing process is completed; heat the mixed powder in the mold to 150- 200°C, keep warm for 1.5h; after the keep warm, gradually increase the pressure. When the temperature drops to 110°C, pressurize 10-20MPa; when the temperature drops to 100°C, pressurize 30-50MPa; when the temperature drops to 90°C, pressurize 70-90MPa; when the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com