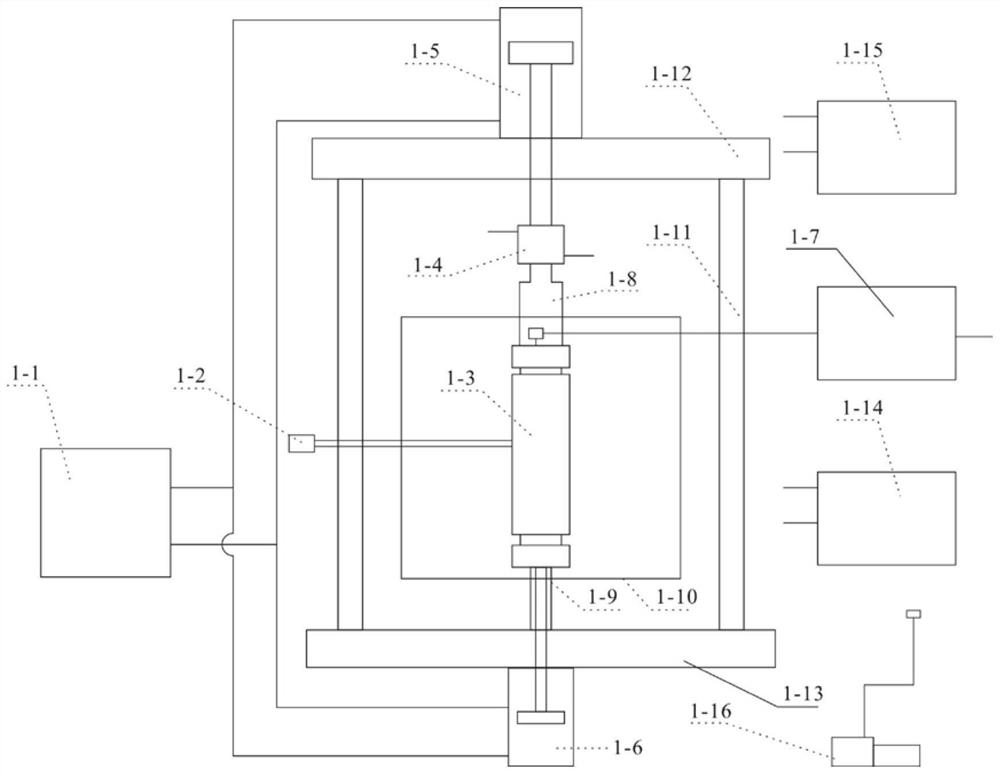

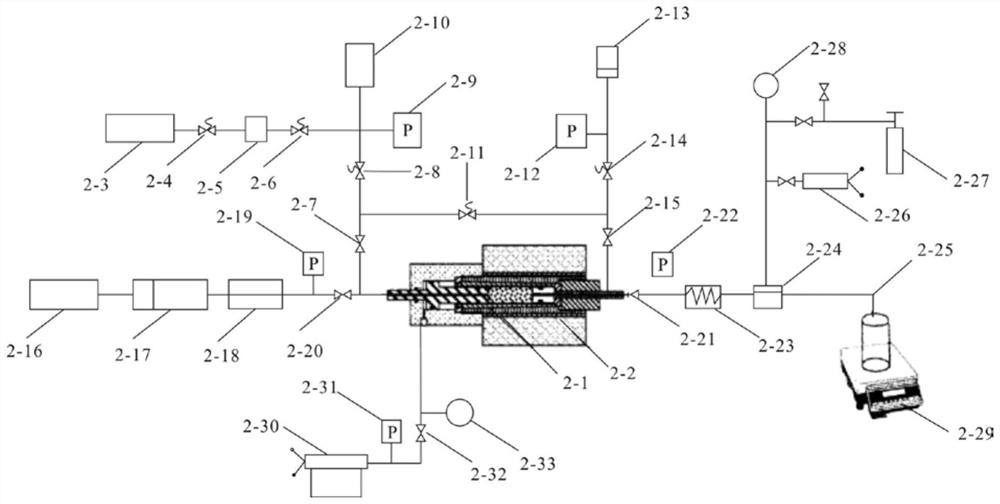

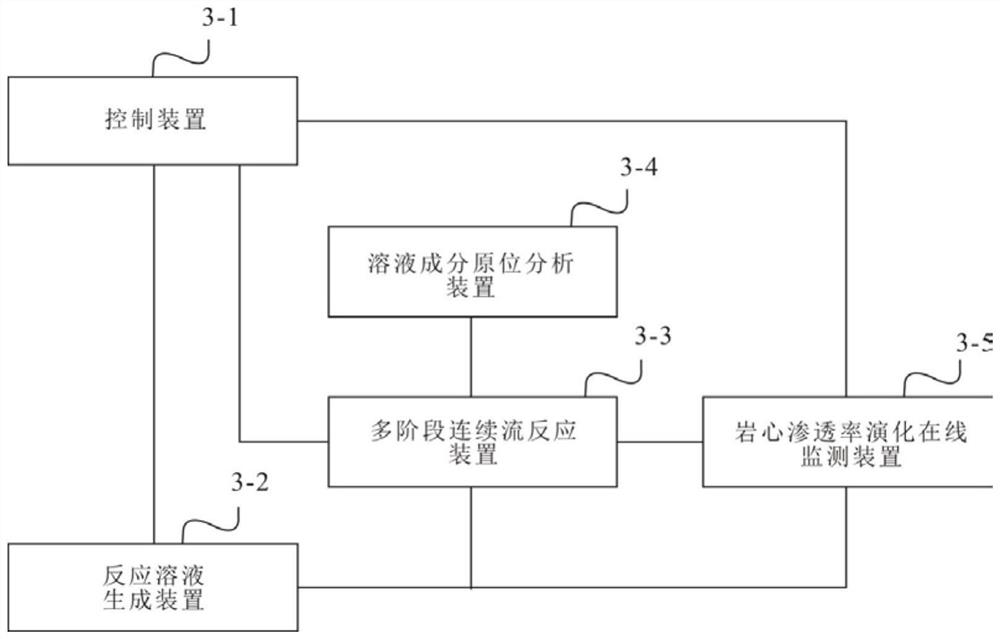

A multifunctional high temperature and high pressure simulation experiment device for hydrocarbon and diagenetic diagenesis and its application method

A simulated experimental device, high temperature and high pressure technology, applied in the direction of material inspection, soil material testing, etc., can solve the problems of failure to realize fluid migration and reaction, low experimental efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0143] Example 1 Simulation experiment of conventional and unconventional natural gas generation in source rocks of Longmaxi Formation

[0144] 1 Sample preparation and preparation

[0145] Select core samples or outcrop samples of immature or low-mature source rock samples similar to the source rock depositional environment, organic matter type, and organic matter abundance in the study area, with Ro ≤ 0.6%, and sample weight ≥ 500g. And select some small pieces of immature and low-mature coal standard samples, Ro≤0.6%. Since the source rocks of the Longmaxi Formation in my country have generally entered the high-over-mature stage, and the types of organic matter are mainly type I-II1, the low-mature source rocks of the Devonian in Luquan, Yunnan were selected as Ro=0.48%, TOC=5.24% . In addition, uncooked Jurassic coal in Cuijiazhai, Hebei Province was selected as the coal standard sample, Ro=0.50%.

[0146] Considering the heterogeneity of the source rock, the sample was ...

Embodiment 2

[0174] Example 2 Simulation experiment on the effect of hydrocarbon-generating fluids of Xujiahe Formation coal-measure source rocks in western Sichuan on feldspar-quartz sandstone reservoirs

[0175] 1 Sample preparation and preparation

[0176] The low-mature coal of the Xujiahe Formation in western Sichuan was selected as the parent rock providing coal-measure source rock = fluid, the sample number is PZ-9-1, the organic carbon content is 67.85%, and the Ro is 0.60%. The core consists of one piece of feldspar sandstone, with a porosity of 21.51% and a permeability of 60.1md. The interaction between hydrocarbon source fluid and reservoir is simulated when Ro=2.0% at the peak of oil generation. The coal PZ-9-1 sample was crushed to 20 mesh, mixed thoroughly, shrunk into several parts, and a small part was taken for each simulated temperature point to be pressed into a small cylindrical core to ensure the uniformity and representativeness of the sample. In addition, uncooked...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com