Nickel paste for multilayer ceramic capacitor based on gravure coating printing and application of nickel paste

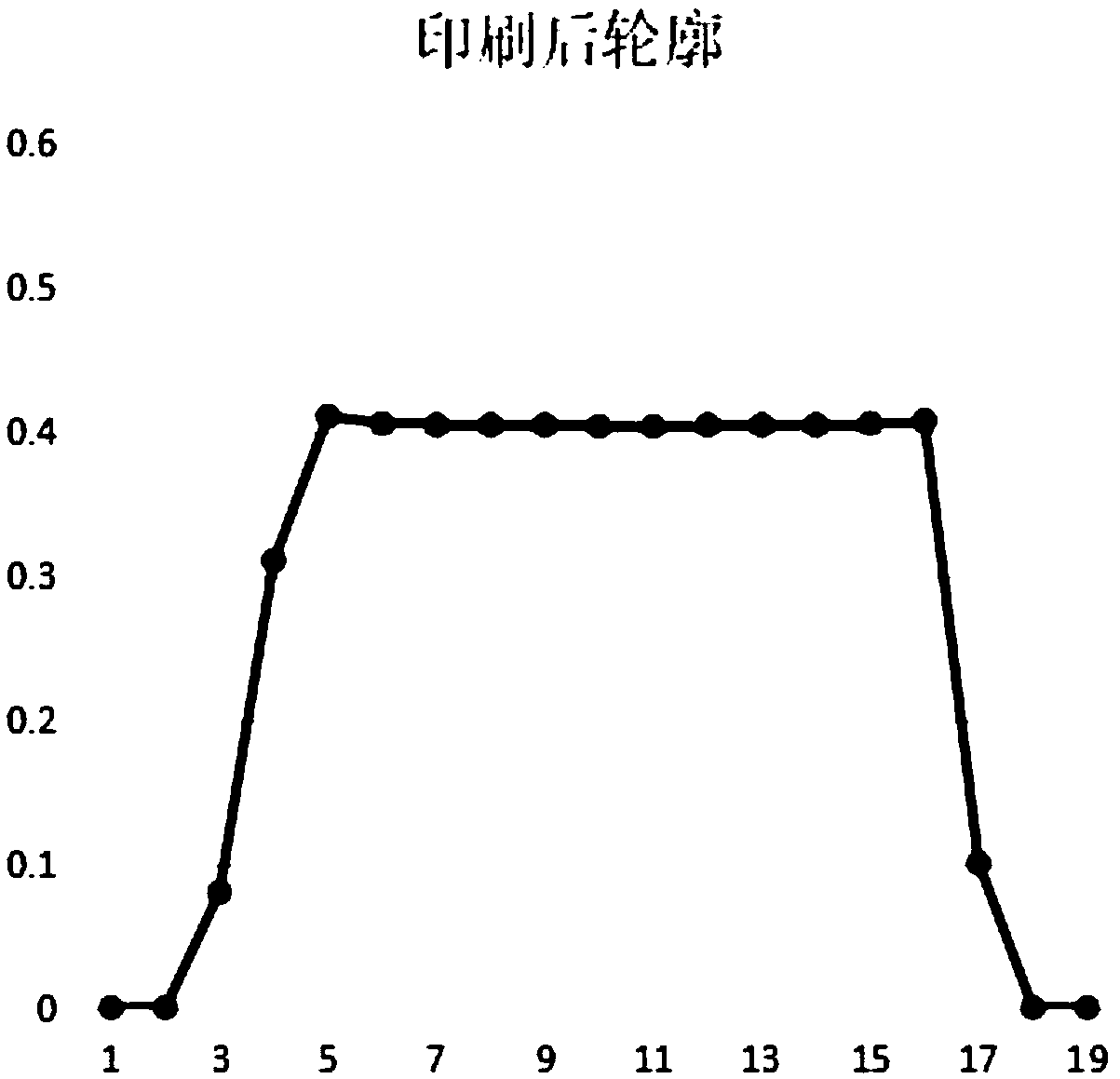

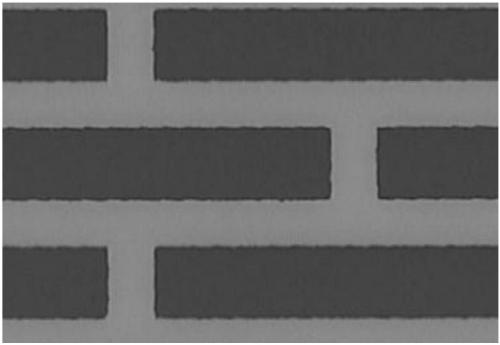

A multi-layer ceramic and capacitor technology, applied in the direction of multilayer capacitors, capacitors, fixed capacitors, etc., to achieve the effect of good continuity, high yield and good graphics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A kind of nickel paste for multilayer ceramic capacitor based on gravure coating printing, its raw material comprises following mass parts material:

[0054] 40-50 parts of nickel powder;

[0055] 5-12 parts of ceramic powder;

[0056] 0.1-2 parts of dispersant;

[0057] 0.1 to 5 parts of plasticizer;

[0058] And glue 22.1~43 parts;

[0059] Wherein, described glue comprises following mass ratio material:

[0060] Organic solvent: resin: thixotropic agent = 80-98: 2-4: 0.1-0.2.

[0061] Described organic solvent is the mixture of one or more in terpineol, dihydroabietyl acetate, terpineol or ethylene glycol ethyl ether acetate, and described organic solvent and described dispersant, described enhancer The plasticizer has good compatibility with the resin.

[0062] The resin is one or a mixture of ethyl cellulose, polyvinyl butyral or polyurethane resin.

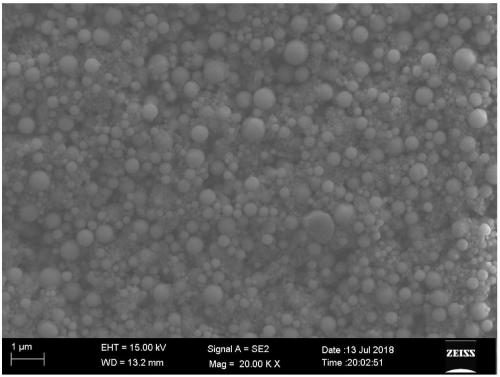

[0063] The ceramic powder is barium titanate with a perovskite structure, and its specific surface area is 4...

Embodiment 2

[0069] A method for preparing nickel paste for multilayer ceramic capacitors based on gravure coating printing, has the following steps:

[0070] S1. Grinding of ceramic powder:

[0071] The ceramic powder is barium titanate with perovskite structure, prepare 100g;

[0072] The ceramic powder is ball milled at a ball milling speed of 2500-3000rpm / min until the specific surface area of the ceramic powder is less than or equal to 15m 2 / g and the particle size is uniform, the ball mill is cooled by external cooling water;

[0073] S2, preparation of glue:

[0074] The organic solvent is 300g of terpineol, the resin is 13g of ethyl cellulose, and the thixotropic agent is 0.6g of polyamide wax;

[0075] Mix and stir the organic solvent, the resin and the thixotropic agent, the stirring time is 6 hours to 8 hours, the stirring temperature is 60-80°C, the stirring speed is 800-1200rpm / min, and the obtained mixture is added Pressure filtration, the filtration pressure is 2-4psi...

Embodiment 3

[0086] A method for preparing nickel paste for multilayer ceramic capacitors based on gravure coating printing, has the following steps:

[0087] S1. Grinding of ceramic powder:

[0088] Ceramic powder is barium titanate with perovskite structure, prepare 110g;

[0089] The ceramic powder is ball milled at a ball milling speed of 2500-3000rpm / min until the specific surface area of the ceramic powder is less than or equal to 15m 2 / g and the particle size is uniform, the ball mill is cooled by external cooling water;

[0090] S2, preparation of glue:

[0091] The organic solvent is 331g of terpineol, the resin is 11.7g of ethyl cellulose, and the thixotropic agent is 0.5g of polyamide wax;

[0092] Mix and stir the organic solvent, the resin and the thixotropic agent, the stirring time is 6 hours to 8 hours, the stirring temperature is 60-80°C, the stirring speed is 800-1200rpm / min, and the obtained mixture is added Pressure filtration, the filtration pressure is 2-4psi, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com