A high Seebeck coefficient aqueous thermochemical battery and device

A thermochemical and water-based technology, applied to thermoelectric devices, aqueous electrolytes, and acidic electrolytes that only use the Peltier or Seebeck effect, can solve problems such as unsatisfactory performance, low Seebeck coefficient, and low thermoelectric conversion efficiency, and achieve thermoelectric Improvement of conversion efficiency, increase of redox reaction entropy, and improvement of Seebeck coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In some embodiments, the preparation method of the aqueous electrolyte includes the following steps:

[0032] (1) Prepare an aqueous redox solution at 20-30°C. Among them, the oxidized and reduced components have equimolar concentrations, and the concentration of the oxidized or reduced components is 0.1 to 2 mol L -1 .

[0033] (2) Add one or more of the above organic small molecule additives to the redox solution obtained in step (1) under stirring conditions to obtain a high Seebeck coefficient aqueous electrolyte.

[0034] The present invention also provides a water system thermochemical battery, which includes the water system electrolyte. Other components in the thermochemical battery can be conventional components. By using the aqueous electrolyte, an aqueous thermochemical battery with a high Seebeck coefficient can be prepared.

[0035]The invention also provides a large-area thermochemical battery device, which includes several single cells integrated in s...

Embodiment 1

[0045] The preparation method of the aqueous thermochemical battery provided in Example 1 comprises the following steps:

[0046] (1) Prepare 50mL 0.4mol L at 25°C -1 K 3 Fe(CN) 6 / K 4 Fe(CN) 6 Clarify the aqueous electrolyte for later use.

[0047] (2) Take 2 mL of the above solution and add 4 g of urea, and fully stir for 30 min at a speed of 600 rpm.

[0048] (3) Add urea and urea-free K 3 Fe(CN) 6 / K 4 Fe(CN) 6 The water-based electrolyte is poured into two polytetrafluoroethylene square tanks, and the upper and lower ends are sealed with two graphite sheet electrodes to obtain a water-based thermochemical battery.

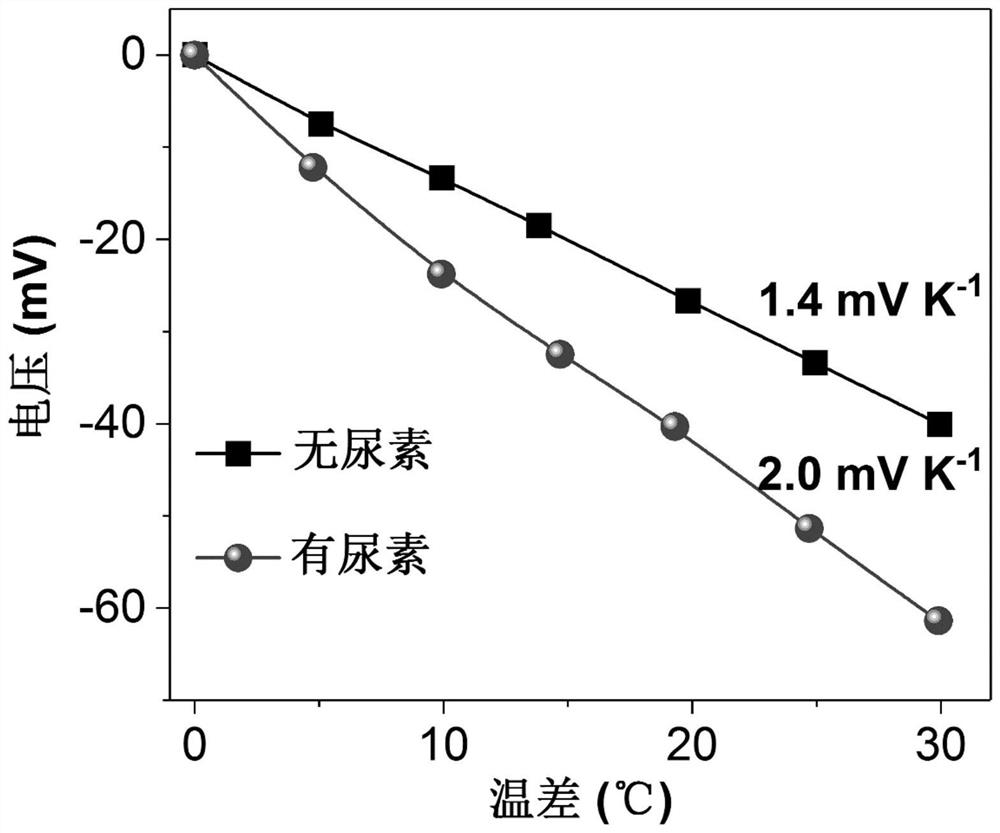

[0049] figure 1 Shown is the comparison of the performance of the aqueous thermochemical battery prepared in Example 1 with and without urea addition. Under the same temperature difference, the thermochemical cell after adding urea can generate a larger open circuit voltage. The temperature difference has a linear relationship with the open circuit...

Embodiment 2

[0051] The method for preparing an aqueous thermochemical battery provided in Example 2 comprises the following steps:

[0052] (1) Prepare 50mL 0.1mol L at 25℃ -1 KI / KI 3 Clarify the aqueous electrolyte for later use.

[0053] (2) Take 2 mL of the above solution and add 0.5 g of guanidine hydrochloride, and fully stir at a speed of 600 rpm for 10 min.

[0054] (3) Add KI / KI with guanidine hydrochloride and guanidine hydrochloride 3 The water-based electrolyte is respectively poured into two phenolic resin square tanks, and the upper and lower ends are sealed with two graphite felt electrodes to obtain a water-based thermochemical battery.

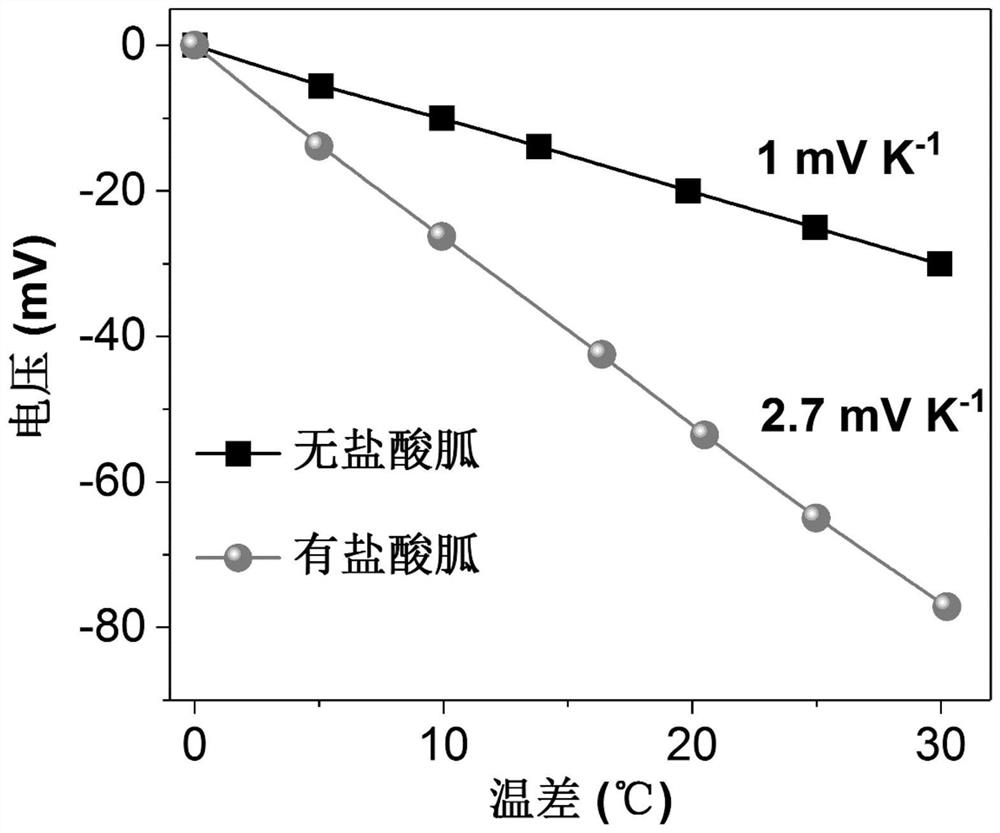

[0055] figure 2 Shown is the comparison of the performance of the aqueous thermochemical cells prepared in Example 2 with and without the addition of guanidine hydrochloride. Under the same temperature difference, the thermochemical cell after adding guanidine hydrochloride can generate a larger open circuit voltage. The temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com