Preparing method of multifunctional protection coating of medical instruments and medical consumables

A technology for medical devices and protective coatings, applied in coatings, medical science, catheters, etc., can solve the problems of poor binding force, short action time, and easy fall-off of bactericidal coatings, and achieve excellent biocompatibility and three-dimensional Anti-corrosion performance, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

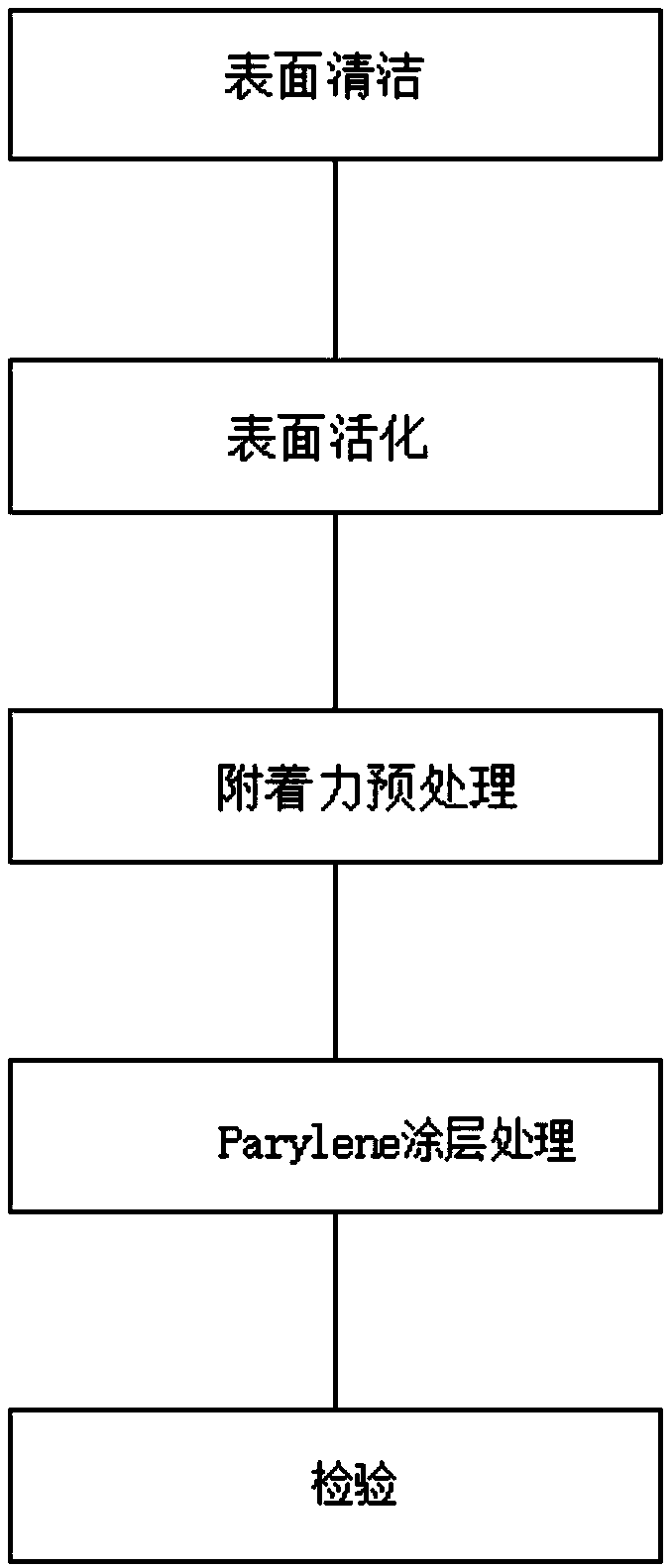

Method used

Image

Examples

Embodiment 1

[0037] Coating medical catheters

[0038] 1. First, clean medical catheters made of polyethylene, latex, etc., first clean with ethanol, clean for 1 hour, clean twice, then clean with deionized water, clean for 0.5 hours, clean three times, and then set Dry in an oven at 50℃ for 6-8h.

[0039] 2. Surface activation treatment

[0040] Plasma surface activation is performed on the cleaned medical catheter. The soft plastic material has a plasma power of 100W and the activation time is 1 to 3 minutes. The hard plastic material has a plasma power of 300 to 500W and the activation time is 5 to 10 minutes.

[0041] 3. Surface adhesion treatment

[0042] The silane G-570 is uniformly sprayed on the surface of the medical catheter by spraying, and the concentration of silane G-570 is 3.5%.

[0043] 4. Coating treatment

[0044] The medical catheter processed by the above steps is placed in the vacuum coating chamber for coating treatment, and the quaternary ammonium salt or antimicrobial peptide...

Embodiment 2

[0050] Coating medical stainless steel wire

[0051] 1. First, clean the stainless steel medical wire, first clean with ethanol, clean for 1.5 hours, clean 3 times, then clean with deionized water, clean for 0.5 hours, clean twice, and then place it at 60°C Dry in an oven for 5-8h.

[0052] 2. Surface activation treatment

[0053] Perform plasma surface activation on the cleaned stainless steel wire with a plasma power of 1000W and an activation time of 5-10 minutes.

[0054] 3. Surface adhesion treatment

[0055] The silane G-570 is uniformly sprayed on the surface of the medical wire by spraying, and the concentration of silane G-570 is 8%.

[0056] 4. Coating treatment

[0057] The medical wire processed by the above steps is placed in the vacuum coating chamber for coating treatment, and the quaternary ammonium salt or antimicrobial peptide is placed in the drug feeding groove in the middle of the coating chamber according to a certain concentration. The concentration is 5-10mg / ml o...

Embodiment 3

[0061] Coating medical silicone material

[0062] 1. First, clean the medical silica gel material, first clean with ethanol, clean for 1 hour, clean twice, then clean with deionized water, clean for 0.5 hour, clean three times, then place it in a 60℃ oven to dry 8 ~15h.

[0063] 2. Surface activation treatment

[0064] Plasma surface activation is performed on the cleaned medical silica gel with a plasma power of 100W and an activation time of 0.5 minutes.

[0065] 3. Surface adhesion treatment

[0066] The silane G-570 is uniformly sprayed on the surface of the medical silica gel by spraying, and the concentration of silane G-570 is 0.5%.

[0067] 4. Coating treatment

[0068] The medical silica gel processed by the above steps is placed in the vacuum coating chamber for coating treatment, and the quaternary ammonium salt or antimicrobial peptide is placed in the drug feeding groove in the middle of the coating chamber according to a certain concentration. Choose 6-12 mg / ml or the conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com