A method for preparing a composite sponge capable of absorbing viscous crude oil

A composite sponge and crude oil technology, applied in chemical instruments and methods, alkali metal compounds, adsorbed water/sewage treatment, etc., can solve problems such as easy failure, safety hazards, etc., and achieve low cost, easy operation, and easy popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

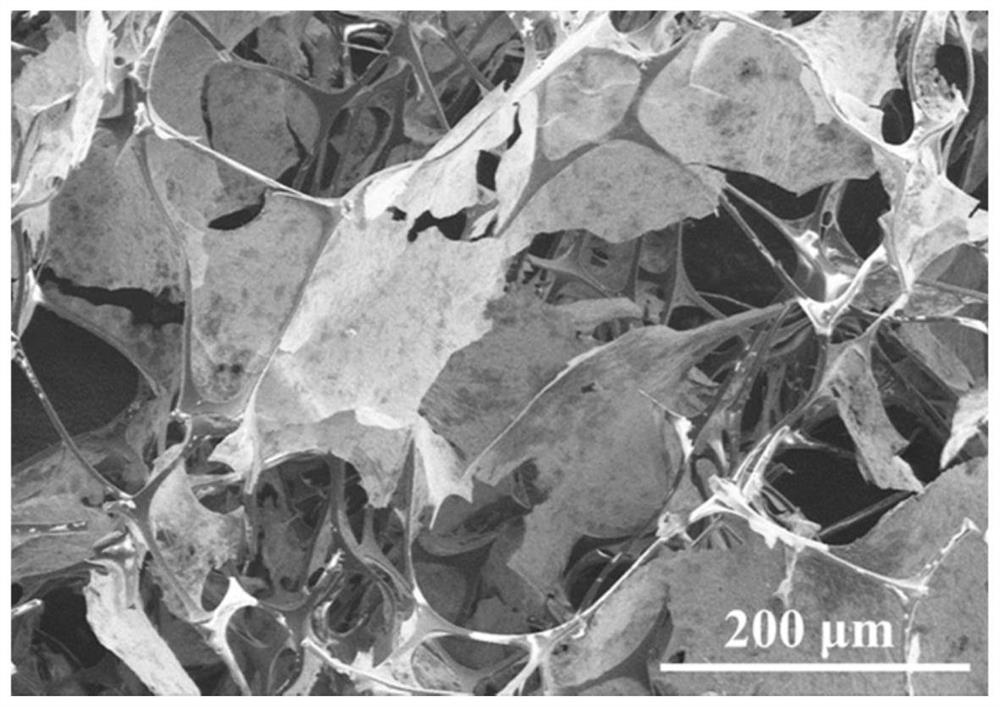

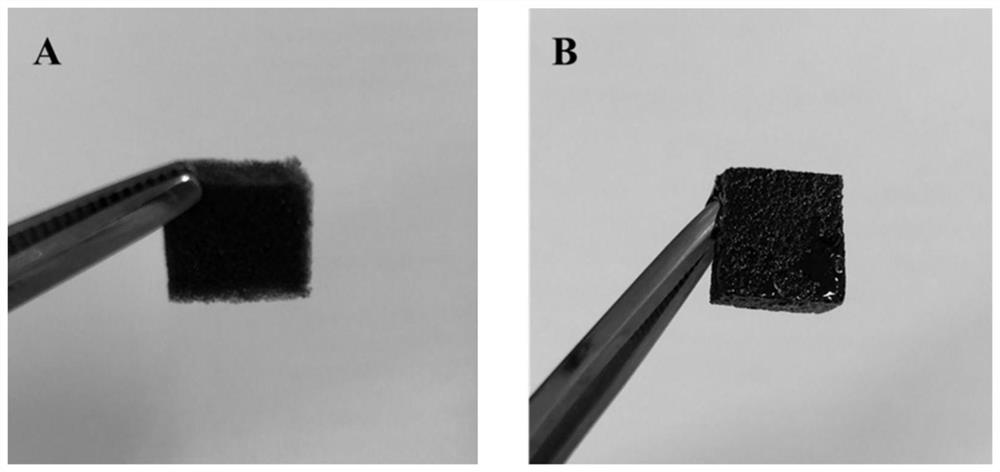

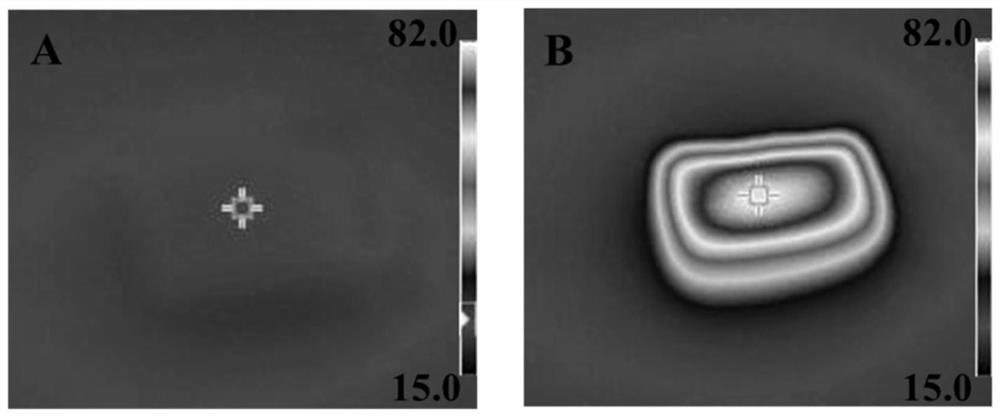

[0033] (1) 90mg graphene oxide powder was added to 30ml pure water, and the 300W ultrasonic 10min of ultrasonic cell disruptor was used to prepare the graphene oxide stock solution of 3mg / ml;

[0034] (2) get 4.667ml graphene oxide stock solution, add 9.305ml pure water, 28 μL ammonia water and 12.3mg L-ascorbic acid;

[0035] (3) drop melamine sponge and above-mentioned solution in 20ml hydrothermal reactor together, carry out hydrothermal reaction, and hydrothermal reaction temperature is 95 ℃, and the time is 60min;

[0036] (4) The reacted sponge is taken out and dried, and the drying temperature is 60° C. and the drying time is 18 hours, so as to obtain a composite sponge capable of absorbing viscous crude oil.

Embodiment 2

[0038] (1) 90mg graphene oxide powder was added to 30ml pure water, and the 100W ultrasonic wave of ultrasonic cell disrupter was used for 30min to prepare the graphene oxide stock solution of 3mg / ml;

[0039] (2) get 4.667ml graphene oxide stock solution, add 9.305ml pure water, 28 μL ammonia water and 12.3mg L-ascorbic acid;

[0040] (3) drop melamine sponge and above-mentioned solution in 20ml hydrothermal reactor together, carry out hydrothermal reaction, and hydrothermal reaction temperature is 95 ℃, and the time is 60min;

[0041] (4) The reacted sponge is taken out and dried, and the drying temperature is 60° C. and the drying time is 18 hours, so as to obtain a composite sponge capable of absorbing viscous crude oil.

Embodiment 3

[0043] (1) 90mg graphene oxide powder was added to 30ml pure water, and the 300W ultrasonic 10min of ultrasonic cell disruptor was used to prepare the graphene oxide stock solution of 3mg / ml;

[0044] (2) get 9.333ml graphene oxide stock solution, add 4.639ml pure water, 28 μL ammonia water and 12.3mg L-ascorbic acid;

[0045] (3) drop melamine sponge and above-mentioned solution in 20ml hydrothermal reactor together, carry out hydrothermal reaction, and hydrothermal reaction temperature is 95 ℃, and the time is 60min;

[0046] (4) The reacted sponge is taken out and dried, and the drying temperature is 60° C. and the drying time is 18 hours, so as to obtain a composite sponge capable of absorbing viscous crude oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com