Catalyst for low-molecular straight-chain paraffin isomerization in Fischer-Tropsch synthesis

A technology of straight-chain alkanes and Fischer-Tropsch synthesis, which is applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, etc., and can solve the problem of small specific surface area and adsorption of pure zirconia Increased capacity and surface acidity, weak surface acidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] (1) The calculated amount of Al(NO 3 ) 3 9H 2 O, zirconium salt (zirconium-aluminum ratio 1:1), lanthanum salt is dissolved in deionized water, (the concentration of zirconium 0.4mol / L, the content of lanthanum 2wt%) drips ammonia water under vigorous stirring and adjusts pH value to be 10;

[0014] (2) Put the mixture into a hydrothermal kettle at 180°C for 24 hours of hydrothermal reaction, wash with water until there is no Cl- and it is neutral;

[0015] (3) Dry the filter cake obtained by washing at 120°C to obtain tetragonal Al 2 o 3 -ZrO 2 carrier.

[0016] (4) Dissolve the zirconium-based composite oxide carrier prepared in step (3) in an aqueous solution of ammonium metatungstate, stir for 6 hours, age for 24 hours, air-dry at 80°C, and roast at 800°C for 4 hours to obtain a W mass fraction of 15%. WO 3 / Al 2 o 3 -ZrO 2 powder;

[0017] (5) WO obtained in step (4) 3 / Al 2 o 3 -ZrO 2 The powder was dispersed in an aqueous solution of nickel nitrate...

Embodiment 2

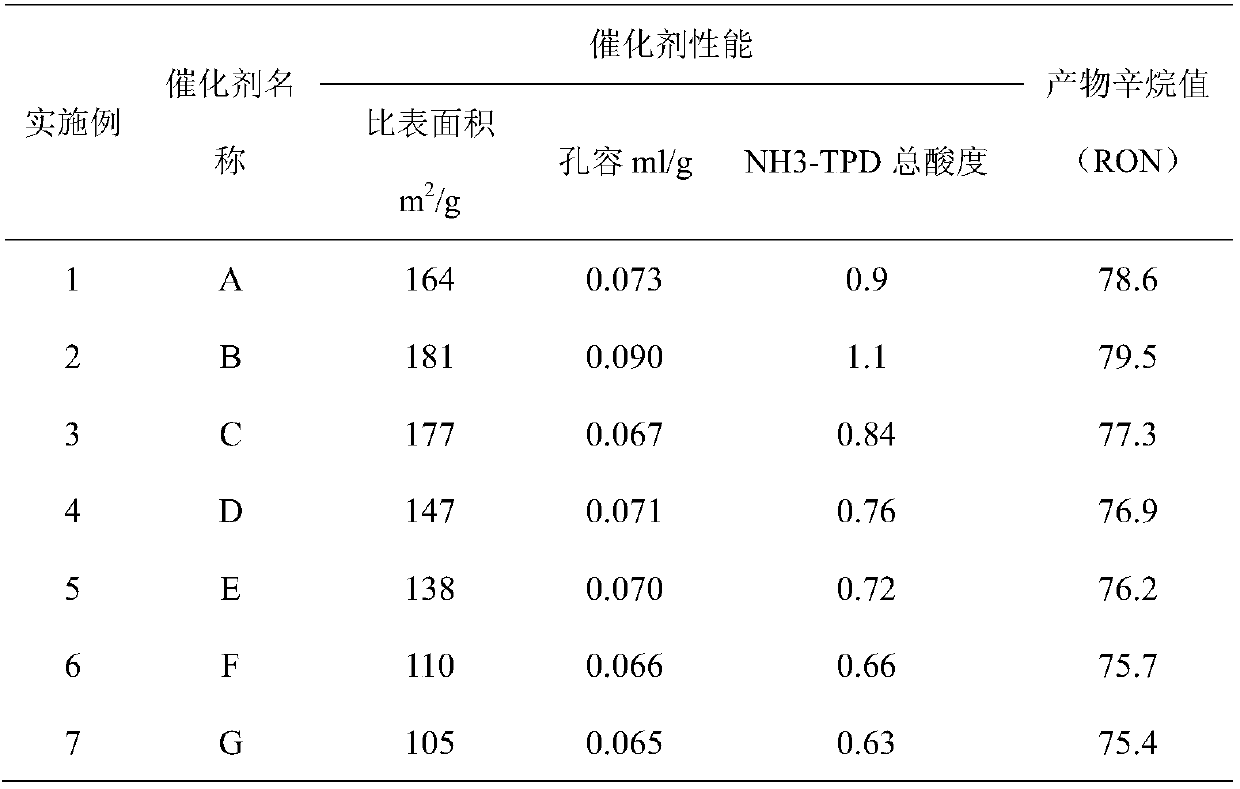

[0019] The operation steps are the same as in Example 1, except that in step (5), the WO obtained in step (4) is modified. 3 / Al 2 o 3 -ZrO 2 The powder was dispersed in an aqueous solution of nickel nitrate, stirred for 6 hours, aged for 24 hours, air-dried at 80°C and calcined at 500°C for 4 hours to obtain Ni-WO with a mass fraction of Ni of 4%. 3 / Al 2 o 3 -ZrO 2 Catalyst, named Catalyst B. Catalyst performance and product octane number are shown in Table 1;

Embodiment 3

[0021] The operation steps are the same as in Example 1, except that in step (5), the WO obtained in step (4) is modified. 3 / Al 2 o 3 -ZrO 2 The powder was dispersed in an aqueous solution of nickel nitrate, stirred for 6 hours, aged for 24 hours, air-dried at 80°C and calcined at 500°C for 4 hours to obtain Ni-WO with a mass fraction of Ni of 6%. 3 / Al 2 o 3 -ZrO 2 Catalyst, named Catalyst C. Catalyst performance and product octane number are shown in Table 1;

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com