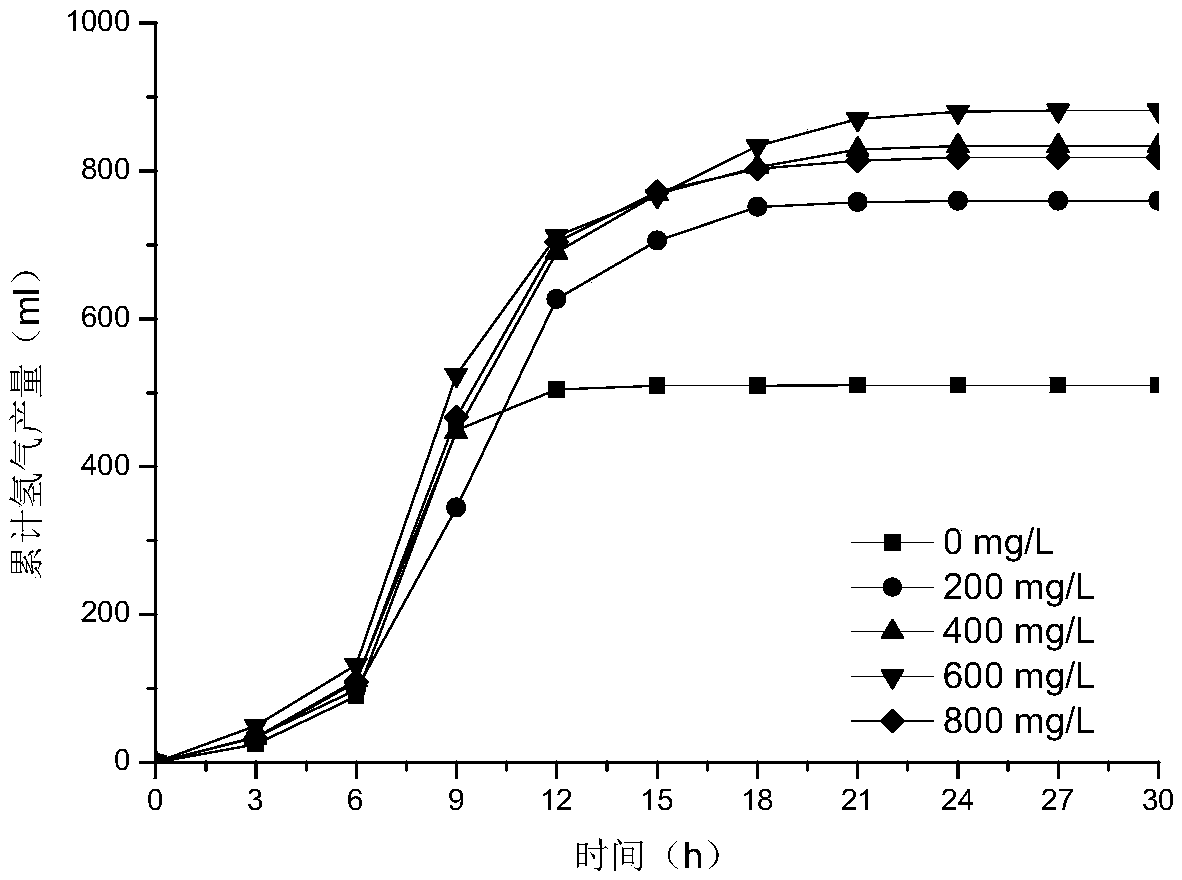

Cobalt-doped magnetic carbon and preparation method and application thereof in anaerobic digestion

A magnetic carbon and magnetic technology, applied in the direction of inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problems that anaerobic microorganisms provide metalloenzymes and metal elements, cannot further improve microbial activity, and the cost of nano-titanium dioxide preparation is high. Recycling and sludge reduction treatment, realizing sludge reduction treatment, and realizing the effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

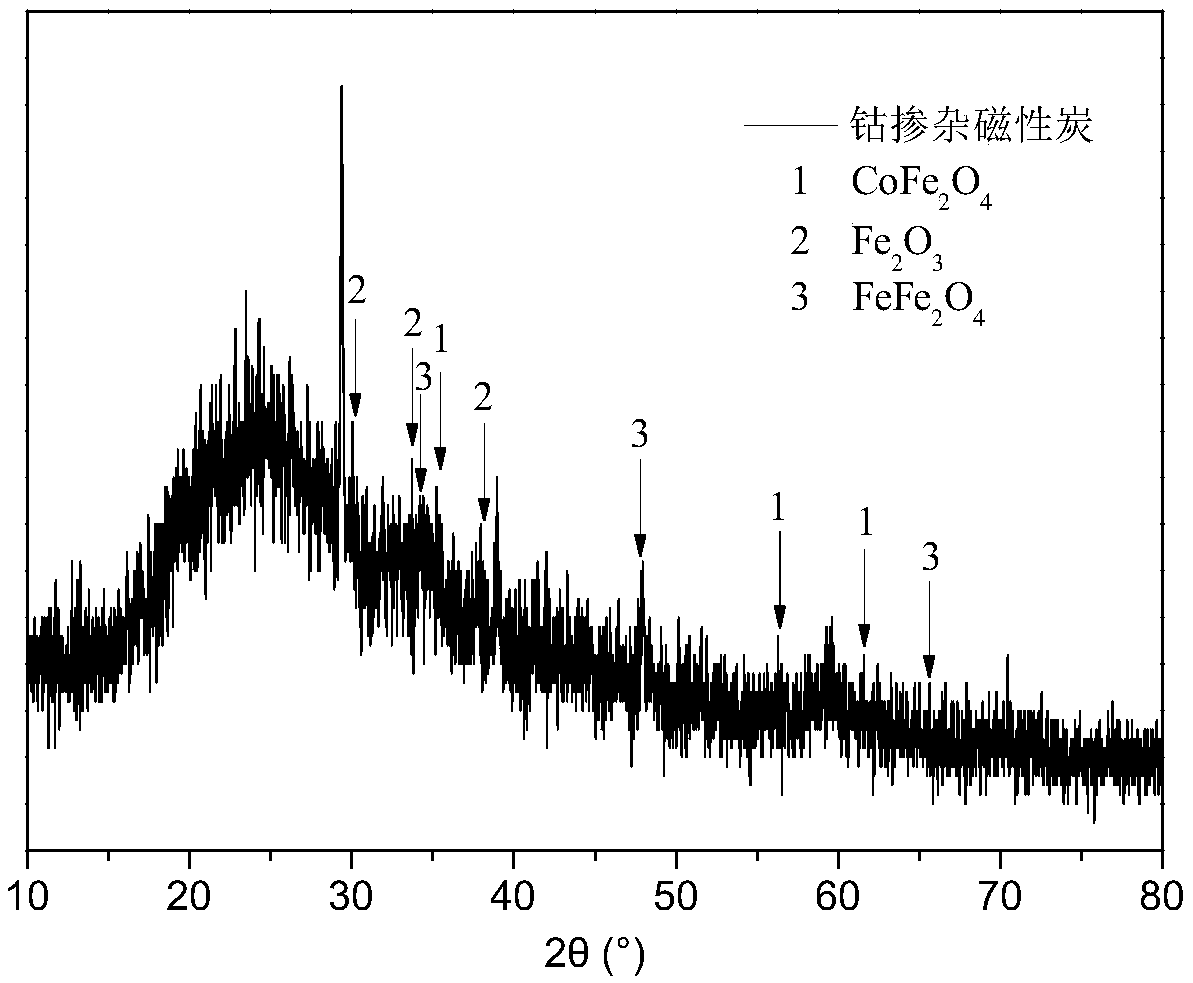

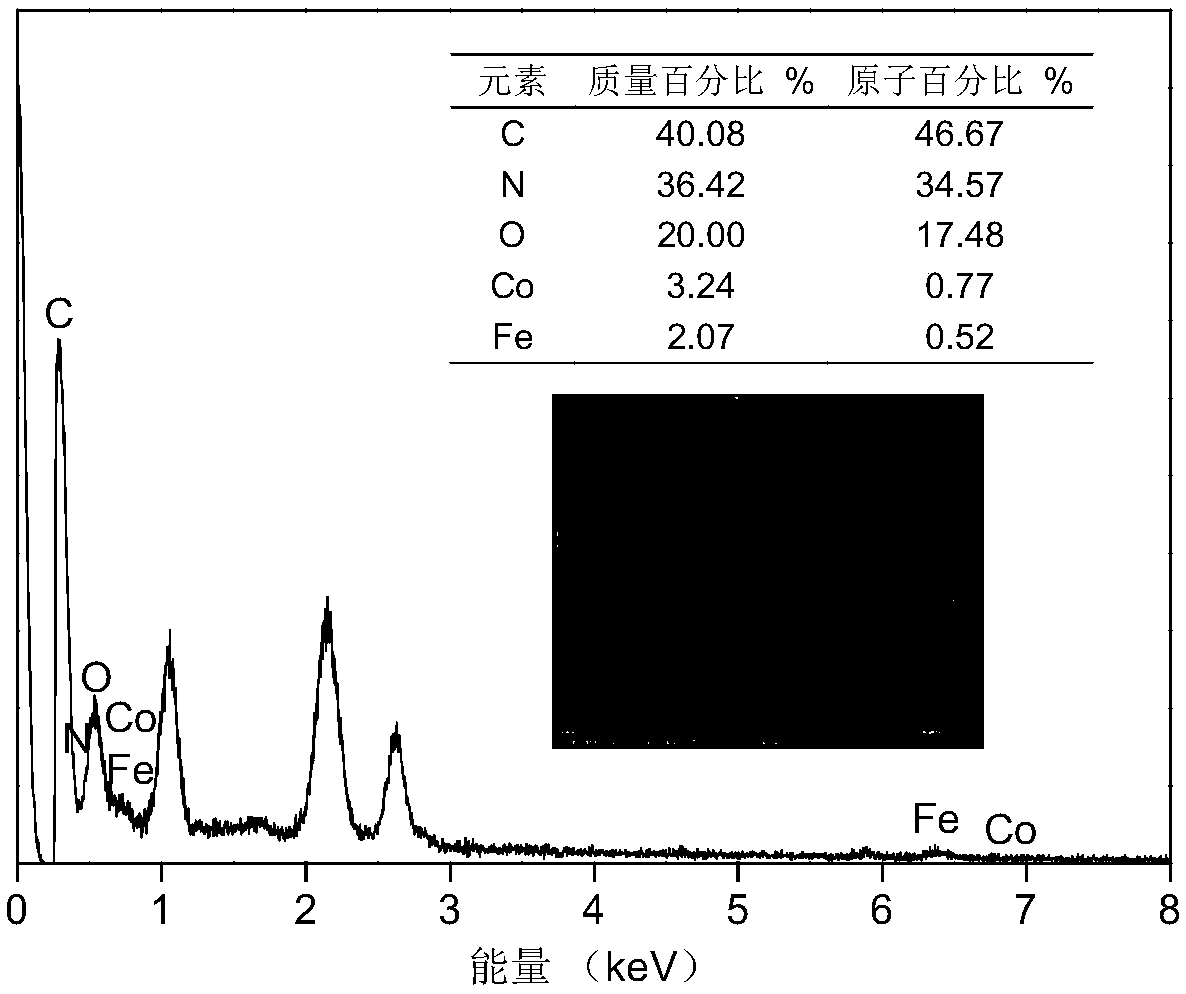

[0065] The preparation method of described cobalt-doped magnetic carbon, concrete steps are as follows:

[0066] A. 5 ~ 6.64g Co (NO 3 ) 2 ·6H 2 O and 7~9.44g Fe(NO 3 ) 3 9H 2 O is dissolved in 200-400ml deionized water to obtain a mixed solution of iron and cobalt; at this time, the solution Co(NO 3 ) 2 The concentration is 12.5~33.2g / L, Fe(NO 3 ) 3 The concentration is 17.5-47.2g / L.

[0067] B. Dissolve 12.5-33.2g of NaOH into 50-150ml of deionized water to obtain a lye with a pH of 9-12. At this time, the NaOH concentration is 46.72-258g / L.

[0068] C. Add 24.6 to 99 g of activated carbon powder into the iron-cobalt mixture described in step A, and stir magnetically for 30 minutes to fully contact the iron ions and cobalt ions with the surface of the activated carbon to obtain the iron-cobalt-carbon mixture.

[0069] D. After heating the mixed solution in an oil bath in the condensing reflux reactor to boiling, quickly pour 50-150ml of NaOH solution and stir evenl...

Embodiment 1

[0079] A. Add 5.82g Co(NO 3 ) 2 ·6H 2 O and 7.76g Fe(NO 3 ) 3 9H 2 O was dissolved in 300ml deionized water to obtain a mixed solution of iron and cobalt. At this point, the Co(NO 3 ) 2 Concentration is 19.4g / L, Fe(NO 3 ) 3 The concentration is 25.8g / L.

[0080] B. Dissolve 6.8g NaOH in 100ml deionized water to obtain a lye with pH=9-12, and the NaOH concentration is 68g / L at this time.

[0081] C. Add 48g of activated carbon powder into the iron-cobalt mixed solution described in step A, and stir magnetically for 30 minutes to fully contact the iron ions and cobalt ions with the surface of the activated carbon to obtain the iron-cobalt-carbon mixed solution.

[0082] D. After the mixture is heated to boiling in an oil bath in the condensing reflux reactor, 100ml NaOH solution is quickly added and stirred evenly with a glass rod, and the reflux reaction temperature is kept at 110°C, and the reaction is kept for 4 hours to complete the reaction.

[0083] E. Dry the m...

Embodiment 2

[0087] A. Add 5g Co(NO 3 ) 2 ·6H 2 O and 7g Fe(NO 3 ) 3 9H 2 O is dissolved in 400ml deionized water to obtain a mixed solution of iron and cobalt. At this time, Co(NO 3 ) 2 Concentration is 12.5g / L, Fe(NO 3 ) 3 The concentration is 17.5g / L.

[0088] B. Dissolve 10.2g NaOH in 75ml deionized water to obtain a lye with pH=9-12, at this time, the concentration of NaOH is 46.72g / L.

[0089] C. Add 99g of activated carbon powder into the iron-cobalt mixed solution described in step A, and stir magnetically for 30 minutes to make the iron ions and cobalt ions fully contact the surface of the activated carbon to obtain the iron-cobalt-carbon mixed solution.

[0090] D. After the mixture is heated to boiling in an oil bath in the condensing reflux reactor, pour 75ml of NaOH solution into it quickly and stir evenly with a glass rod. And keep the reflux reaction temperature at 120°C and the reaction time for 3 hours to make the reaction complete.

[0091] E. Dry the mixed sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com