Wear-resisting waterborne stoving varnish and manufacturing method thereof

A manufacturing method and water-based technology, applied in coatings, polyester coatings, etc., can solve the problems of insufficient color transparency of finished products, high technological level requirements, and high prices, etc., to achieve bright colors, good wettability, and surface. Good smoothness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

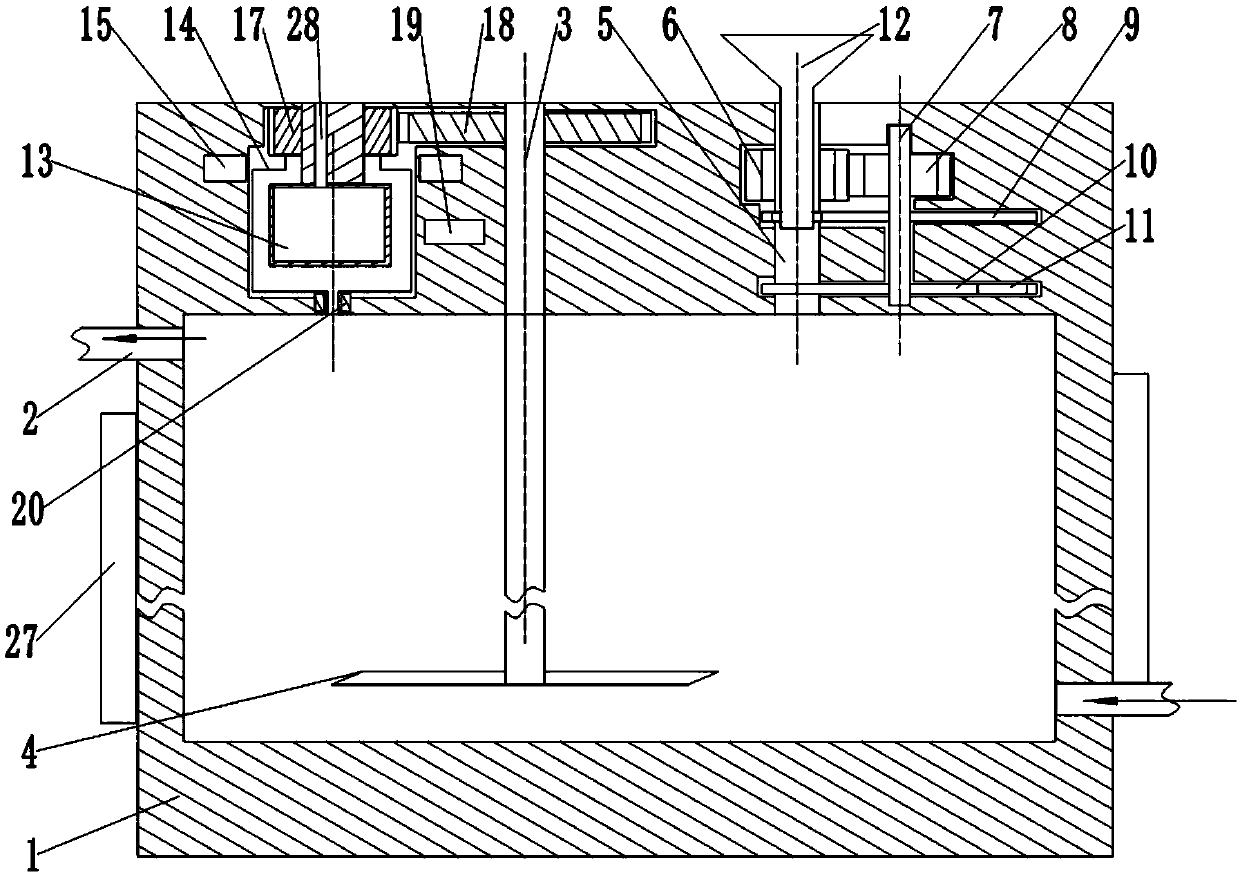

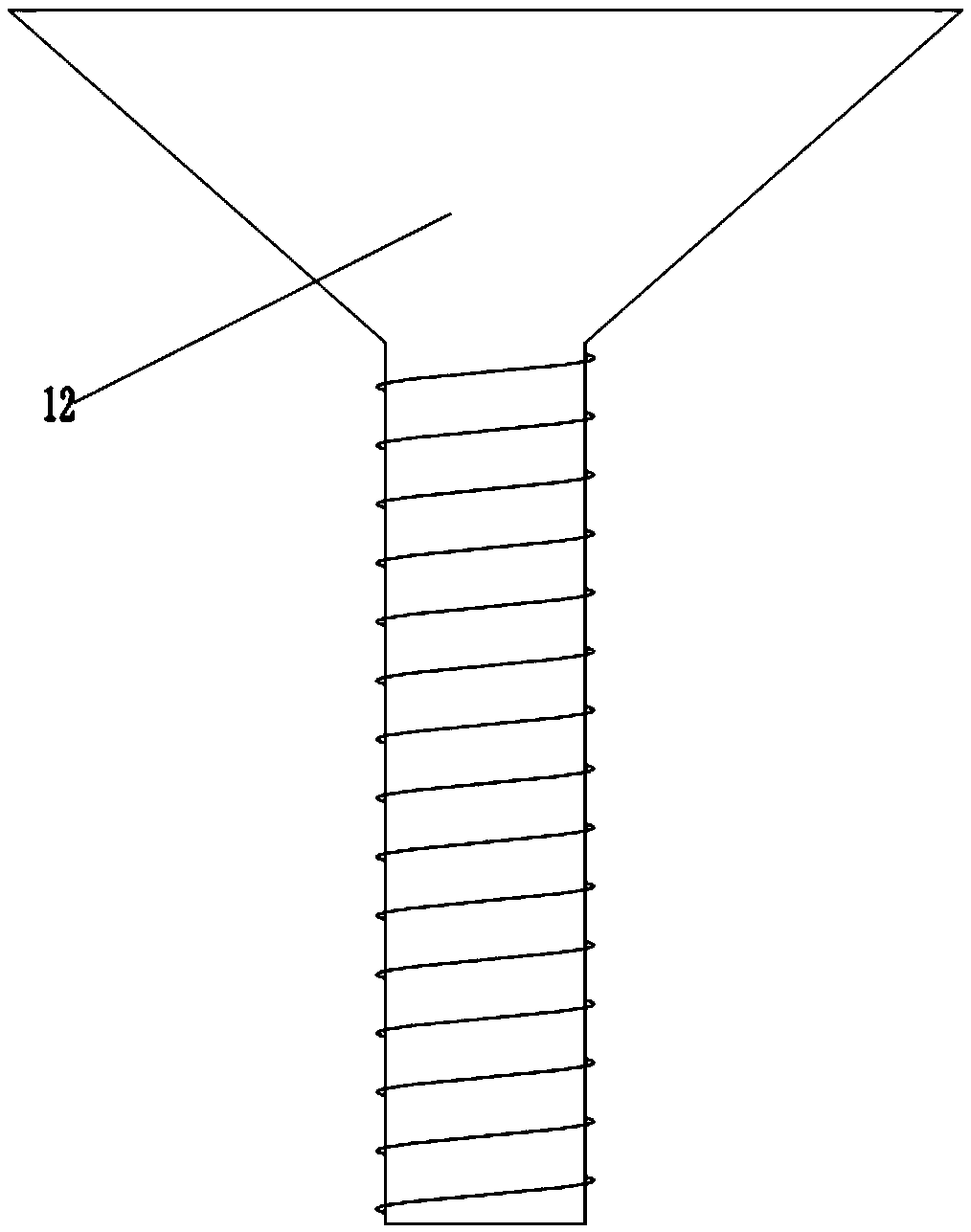

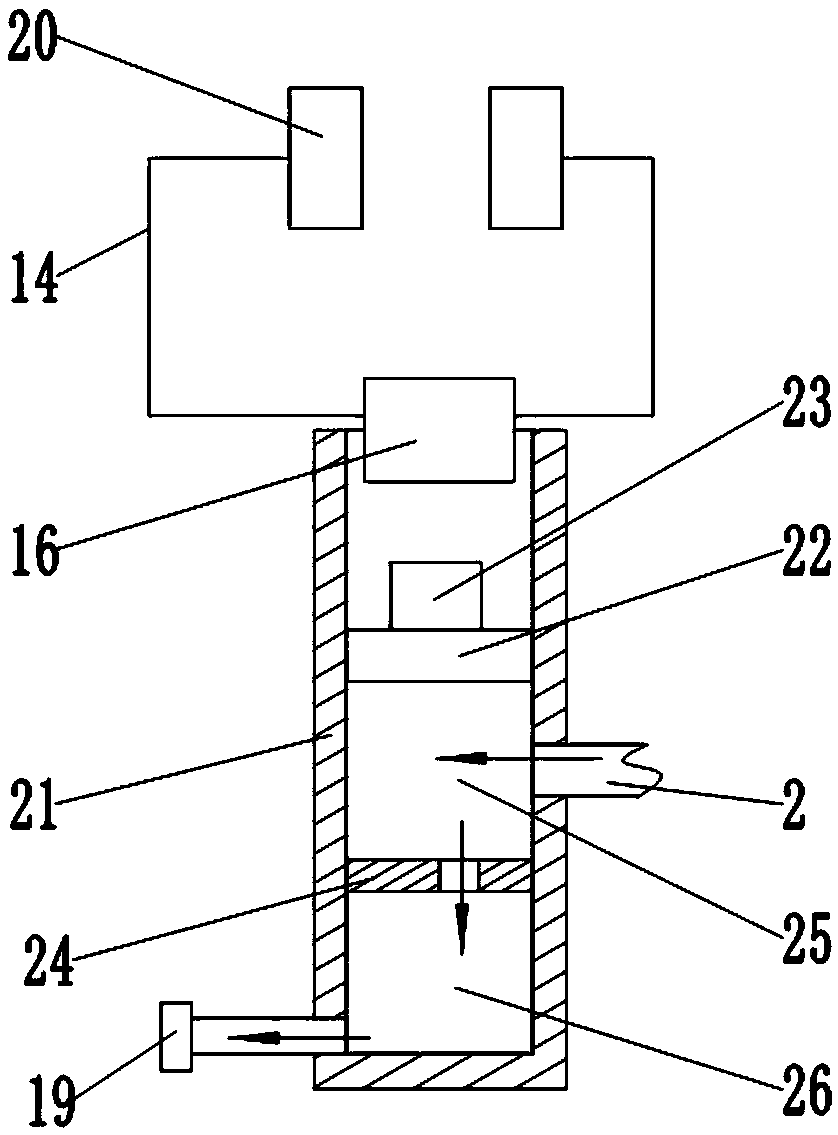

[0032] A wear-resistant water-based baking varnish, the production raw materials and their mass parts are as follows, including resin, resin aqueous solution and color paste; 9.5 parts, 10.1 parts of trimethylolpropane, 23.1 parts of adipic acid, 19.6 parts of 4-butanediol and 9.9 parts of butyl cellosolve; the aqueous resin solution includes 100 parts of water-soluble oil-free alkyd resin, 6.0 parts of dimethylethanolamine , 149.1 parts of deionized water and 50.2 parts of glass fiber; the color paste includes 89 parts of resin aqueous solution, 20 parts of metal particles and 70.1 parts of titanium dioxide. In this embodiment, the glass fiber is made of molten glass into glass balls with a diameter of 15 mm, and then heated and remelted to make very fine fibers with a diameter of 3-80 μm. The heating method is common knowledge and will not be repeated here.

[0033] Its manufacturing method comprises the following steps:

[0034] Step 1, preparation of water-soluble oil-fre...

Embodiment 2

[0046] The difference between this example and Example 1 is that the resin includes 24.9 parts of isophthalic acid, 14.9 parts of trimellitic anhydride, 10.5 parts of hexadecanyl succinic anhydride, 14.5 parts of trimethylolpropane, adipic acid 25.0 parts, 20.5 parts of 4-butanediol, 11.9 parts of butyl cellosolve; Resin aqueous solution comprises 100 parts of water-soluble oil-free alkyd resins, 7.9 parts of dimethylethanolamine, 1151.0 parts of deionized water, 60.8 parts of glass fibers; In the example, the glass fiber is made of molten glass into a glass rod with a diameter of 15 mm, and then reheated and remelted to make a very fine fiber with a diameter of 3-80 μm. The heating method is common knowledge and will not be repeated here. The color paste includes 95 parts of resin aqueous solution, 22 parts of metal particles and 70.1 parts of titanium dioxide. In step 1, raise the temperature to 210°C while stirring, keep it warm for 2 hours, and then add 9.9 parts of butyl ...

Embodiment 3

[0048] Resins include 20.0 parts of isophthalic acid, 12.5 parts of trimellitic anhydride, 9.8 parts of hexadecanyl succinic anhydride, 12.0 parts of trimethylolpropane, 24 parts of adipic acid, 19.8 parts of 4-butanediol, butyl solvent 1.8 parts of fiber agent; resin aqueous solution includes 100 parts of water-soluble oil-free alkyd resin, 7.6 parts of dimethylethanolamine, 150.2 parts of deionized water, 58.8 parts of glass fiber; color paste includes 93.2 parts of resin aqueous solution, 25 parts of metal particles and titanium White powder 73.5 parts. While stirring in step 1, raise the temperature to 205 degrees, keep it warm for 2 hours, and then add 10.4 parts of butyl cellosolve after cooling to below 100 degrees for dilution. Add 55.6 parts of glass fiber in step 2. In step 3, titanium dioxide was added into a grinder and ground for 1.2 hours to obtain nano titanium dioxide, and then 73 parts of nano titanium dioxide was added to the aqueous resin solution for mixin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com