Preparation and application of amphiphilic calcite type calcium carbonate

A calcite type, calcium carbonate technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problem of easy agglomeration of calcium carbonate, and achieve the effects of simple preparation process, low production cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A kind of preparation method of amphipathic calcite type calcium carbonate, comprises the following steps:

[0044] Step 1, the preparation of solution, respectively prepare 0.1M calcium chloride solution and sodium carbonate solution of 50ml;

[0045] Step 2, the addition of the template agent, 0.05g template agent polyoxyethylene polyoxypropylene ether diblock copolymer (F127) is added in the calcium chloride solution of step 1, stirs 2h on the magnetic stirrer, obtains the chlorine containing template agent Calcium solution;

[0046] Step 3, the preparation of amphiphilic calcite type calcium carbonate, under certain conditions, the sodium carbonate solution of 50ml step 1 is added dropwise to the calcium chloride solution containing template agent of step 2 and fully reacts, obtains calcium carbonate precipitation, then through ethanol and The amphiphilic calcite-type calcium carbonate can be obtained by washing with water three times and drying.

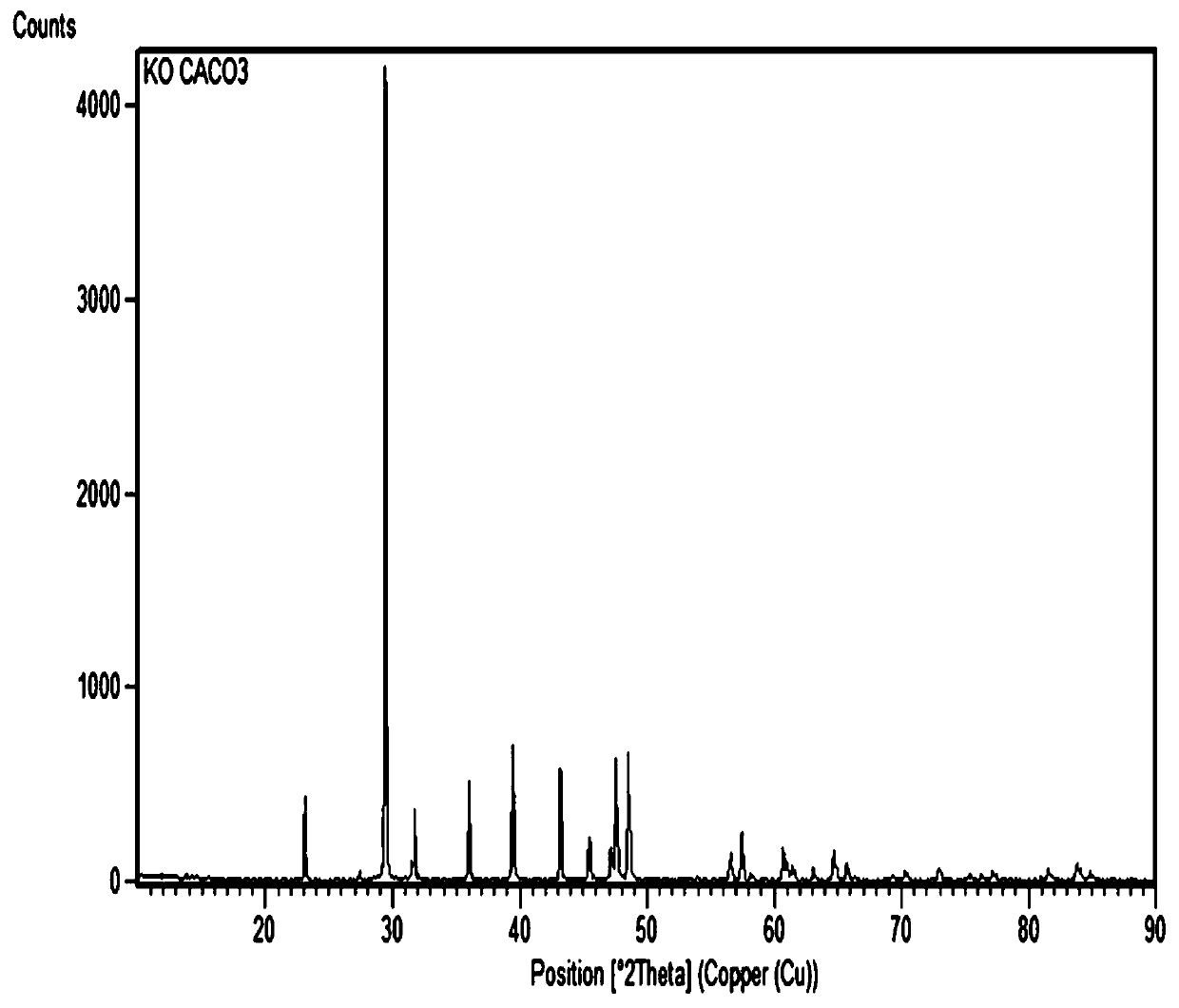

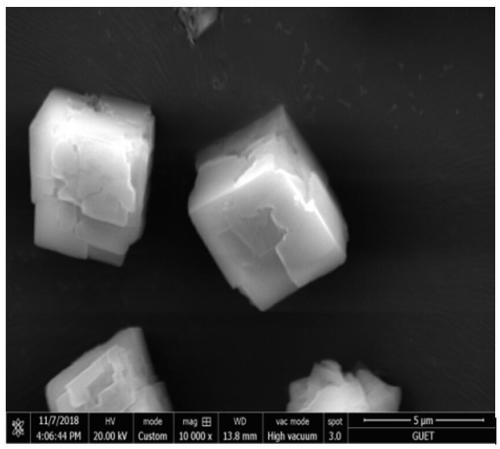

[0047] The XRD ...

Embodiment 2

[0056] A kind of preparation method of amphipathic calcite type calcium carbonate is identical with embodiment 1.

[0057] The application of amphiphilic calcite-type calcium carbonate as an electronic packaging material, the steps not specifically described are the same as in Example 1, except that 10 g of amphiphilic calcite-type calcium carbonate is added.

[0058] The thermal diffusivity test of the composite electronic packaging material, the results are shown in the third column of Table 1, and the thermal diffusivity is 0.0031.

Embodiment 3

[0060] A kind of preparation method of amphipathic calcite type calcium carbonate is identical with embodiment 1.

[0061] The application of amphiphilic calcite-type calcium carbonate as an electronic packaging material, the steps not specifically described are the same as in Example 1, except that 20 g of amphiphilic calcite-type calcium carbonate is added.

[0062] The thermal diffusivity test of electronic packaging materials, the results are shown in column 4 of Table 1, and the thermal diffusivity is 0.0042.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com