A kind of pretreatment and anaerobic digestion treatment method of high solid content sludge

A high solid content and pretreatment technology, applied in biological sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of low methane production and thermal hydrolysis efficiency reduction, and achieve methane production Effects of increasing and diluting inhibitory substances and reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] According to the above technical solution, the thermal hydrolysis device in this embodiment consists of a pressure reaction vessel and heating equipment. The pressure reaction vessel is a cylindrical digestion tank. The tank body of the reaction tank is made of stainless steel, and the inner liner is a polytetrafluoroethylene digestion tank. The effective volume is 200mL, the working temperature is <250°C, and the working pressure is <3.0MPa. The heating equipment is a digital display constant temperature oil bath, equipped with two sets of temperature detection systems, and the heating medium is dimethyl silicone oil.

[0072] Add a certain brand of hot pot bottom material to 500ml of water, boil, cool, and separate the upper layer of fat, which is solid at room temperature.

[0073] Step 1: Preparation of mixed sludge:

[0074] Evenly mix kitchen oil and high-solid sludge, the mixing ratio is 0.2g oil / g high-solid sludge, take 17g kitchen oil and 83g high-solid sludg...

Embodiment 2

[0080] The thermal hydrolysis device in this embodiment consists of a pressure reaction vessel and heating equipment. The pressure reaction vessel is the same as in Example 1.

[0081] The anaerobic digestion test device includes a constant temperature oscillator and an anaerobic digestion reactor. The anaerobic digestion reactor includes a reaction bottle, a gas collection bottle and a gas volume measurement bottle, and the gas production is measured by the drainage gas collection method.

[0082] Add a certain brand of hot pot bottom material to 500ml of water, boil, cool, and separate the upper layer of fat, which is solid at room temperature.

[0083] Step 1: Preparation of mixed sludge:

[0084] Evenly mix kitchen oil and high-solid sludge, the mixing ratio is 0.2g oil / g high-solid sludge, take 17g kitchen oil and 83g high-solid sludge and mix evenly to obtain 100g mixed sample;

[0085] Step 2: thermal hydrolysis:

[0086] Take 100g of the mixed sample and place it i...

Embodiment 3

[0097] This embodiment is basically the same as Example 1, the difference is that the mixing ratio of kitchen grease and high-solid sludge in this embodiment is 0.4g grease / g high-solid sludge, and 29g of kitchen grease and 71g high-solid sludge The mud is evenly mixed, and 100g of the mixed sample is taken for testing.

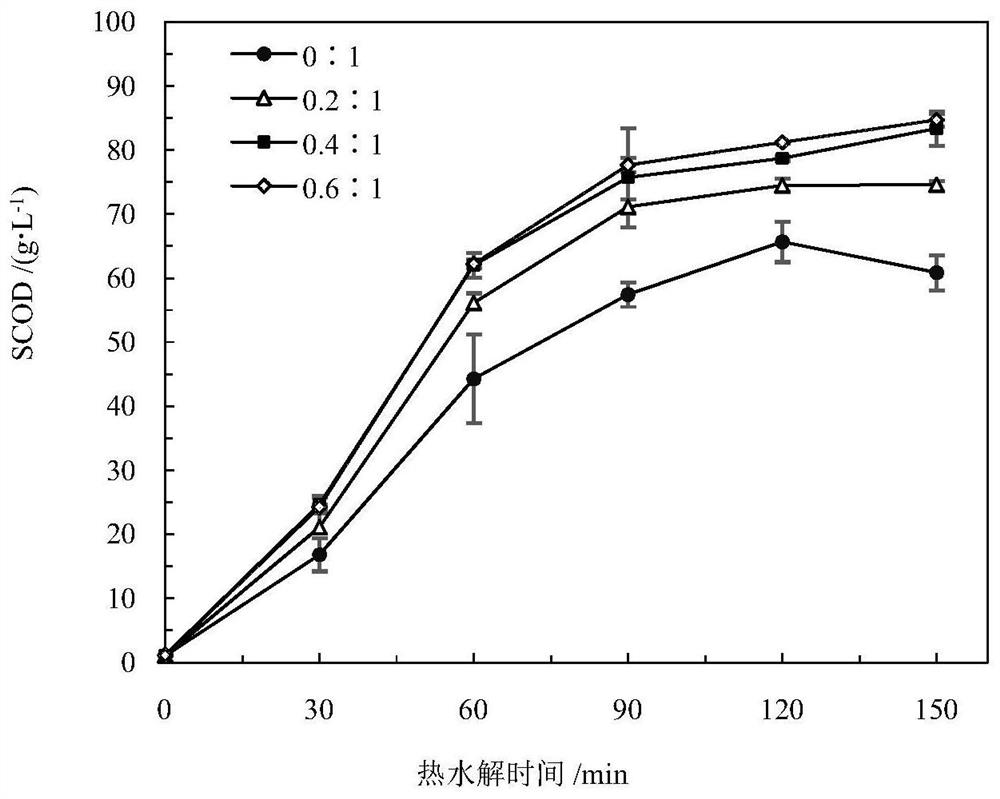

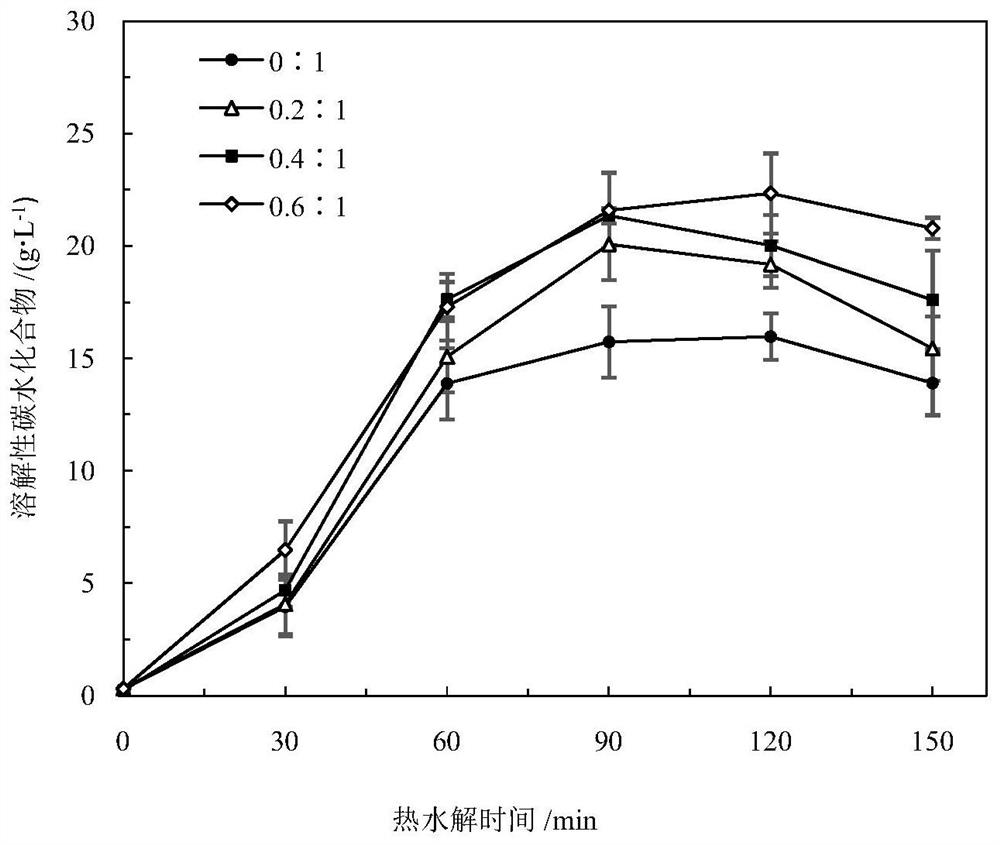

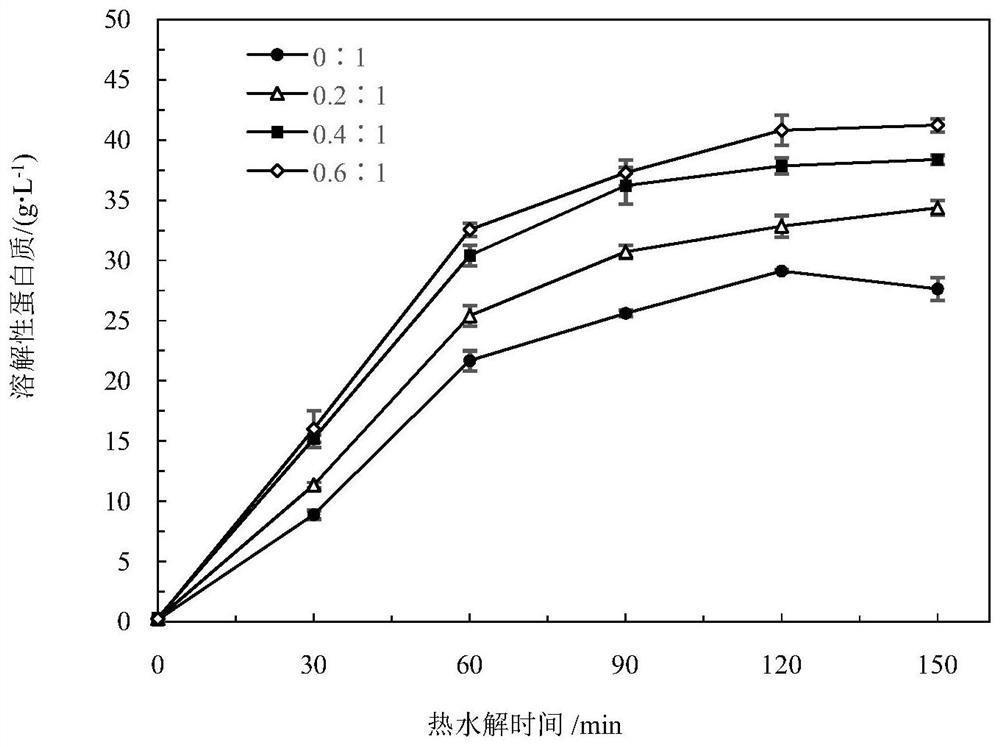

[0098] Combined with the manual figure 1 , 2 , 3, and 4 can be obtained. When the mixing ratio of kitchen oil and high-solid sludge is 0.4g oil / g high-solid sludge, after thermal hydrolysis, the thermal hydrolysis time is 90min, and the SCOD and solubility in the cells The release of carbohydrates, soluble protein, and ammonia nitrogen increased significantly, indicating that oil can accelerate heat transfer and promote the dissolution of insoluble organic matter. Among them, SCOD increased by 31.9±5.1%, soluble carbohydrates increased by 35.7±2.1%, soluble proteins increased by 41.4±5.4%, and ammonia nitrogen increased by 58.6±5.6%.

[0099] Combined with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com