Sulfur concrete with sublimation corrosion resistance and preparation method thereof

A sulphur concrete and sulphur technology, applied in the field of polymer materials, can solve the problems of not meeting the long-term use of lunar sulphur concrete, high sublimation rate of sulphur concrete, affecting service time, etc. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

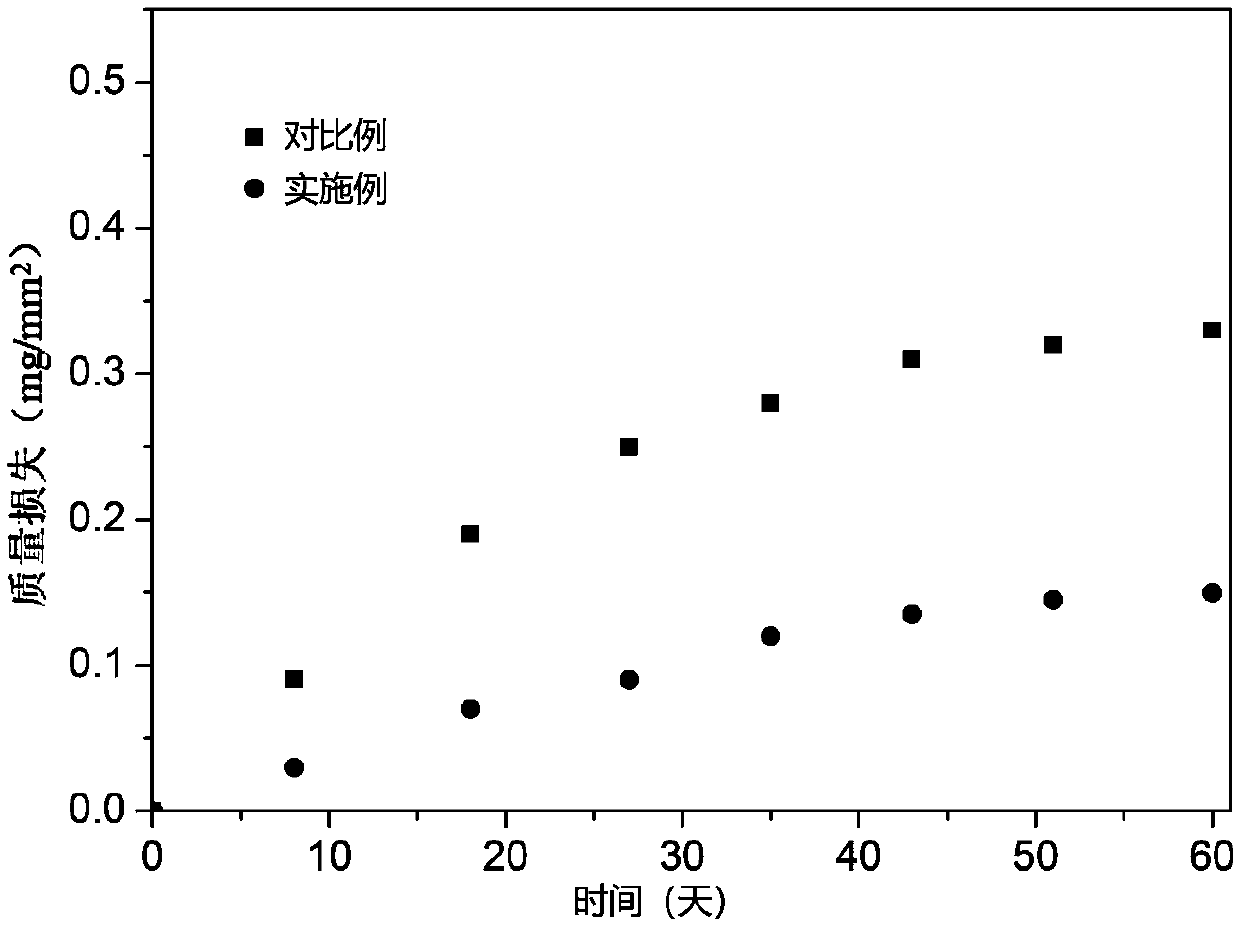

[0024] Aiming at the problem that the existing sulfur concrete has a high sublimation rate and cannot meet the long-term use of lunar sulfur concrete; the invention provides a kind of anti-sublimation corrosion sulfur concrete for a lunar base and a preparation method thereof; It can increase the transition temperature of sulfur cementitious materials directly from solid to gas in high vacuum environment, and reduce the sublimation rate of sulfur concrete.

[0025] The application principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] The anti-sublimation corrosion sulfur concrete provided by the embodiments of the present invention consists of 15% to 20% of sulfur, 0.2% to 0.6% of admixture, 55% to 65% of lunar rock coarse aggregate and 14% to 26% of lunar soil filler according to the mass percentage composition.

[0027] The admixture is a modified component of sulfur, including magnesium stearate, fluori...

Embodiment 1

[0036] The anti-sublimation corrosion sulfur concrete provided by the embodiment of the present invention is calculated by mass percentage, sulfur is 18.5% of the total mass, admixture is 0.5%, lunar rock coarse aggregate is 61%, and lunar soil filler is 20%. The admixture is magnesium stearate: fluorinated polystyrene: carbon tetrafluoride = 1:5:20 by mass ratio, and the amount of admixture is about 2.7% of the mass of sulfur. The coarse aggregate of lunar rock is basalt on the ground, with a particle size of 15-45 mm; the raw material of lunar soil filler is low-titanium simulated lunar soil (CLRS-1) jointly developed by Guiyang Institute of Geochemistry, Chinese Academy of Sciences and the National Astronomical Observatory. Lunar soil filler with a particle size of 0.1-1mm.

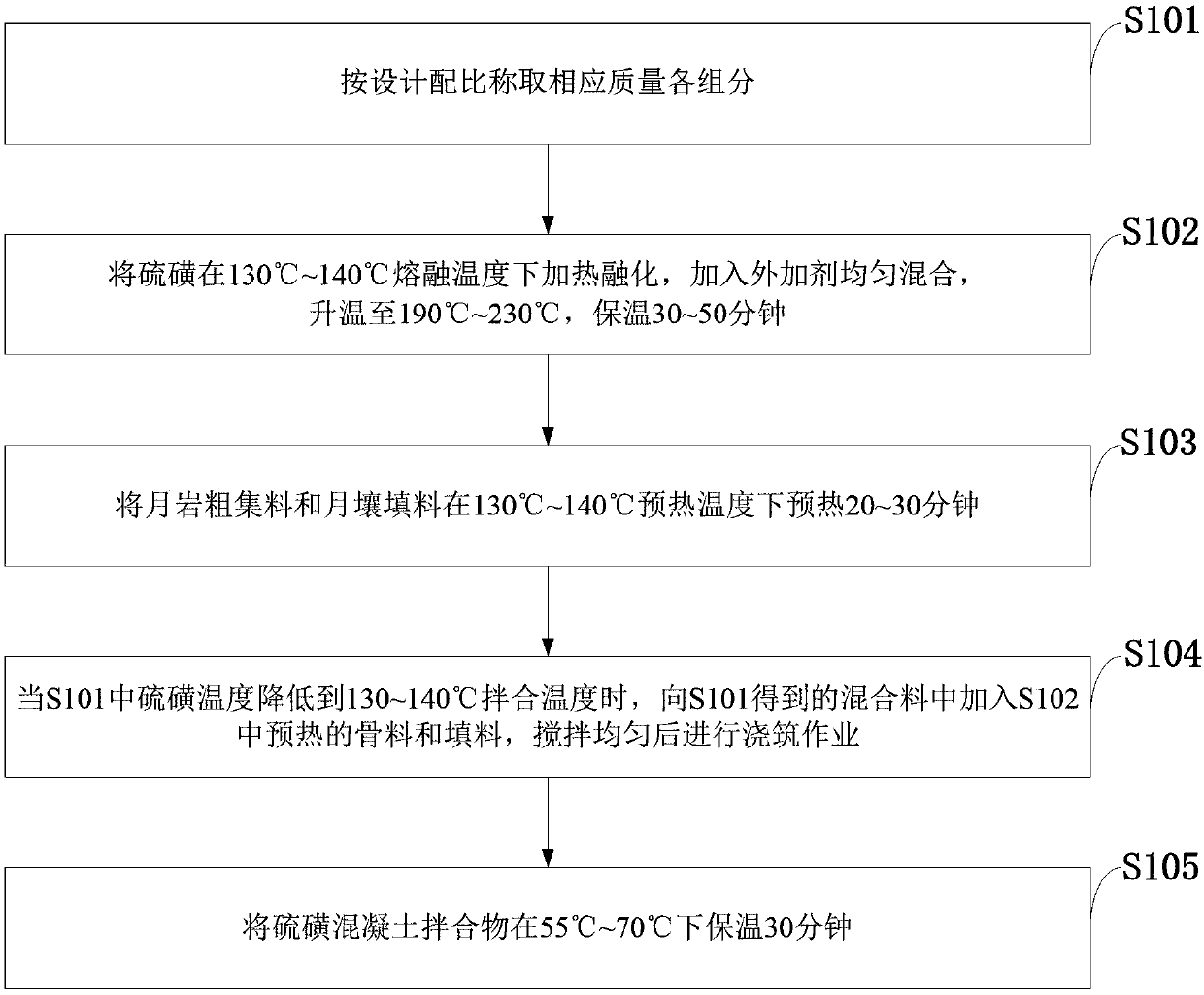

[0037] The preparation method of the anti-sublimation corrosion sulfur concrete provided by the embodiment of the present invention comprises the following steps:

[0038] Step 1: Weigh each component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com