Production method of ethylene diaminetetraacetic acid ferric sodium salt

A technology of ferric sodium edetate and tetrasodium edetate, which is applied in the field of biology and new medicine, can solve the problems of reducing product purity, difficult separation of by-products, and difficulty in mother liquor recycling, so as to reduce raw material consumption and waste, to achieve the effect of material and liquid recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

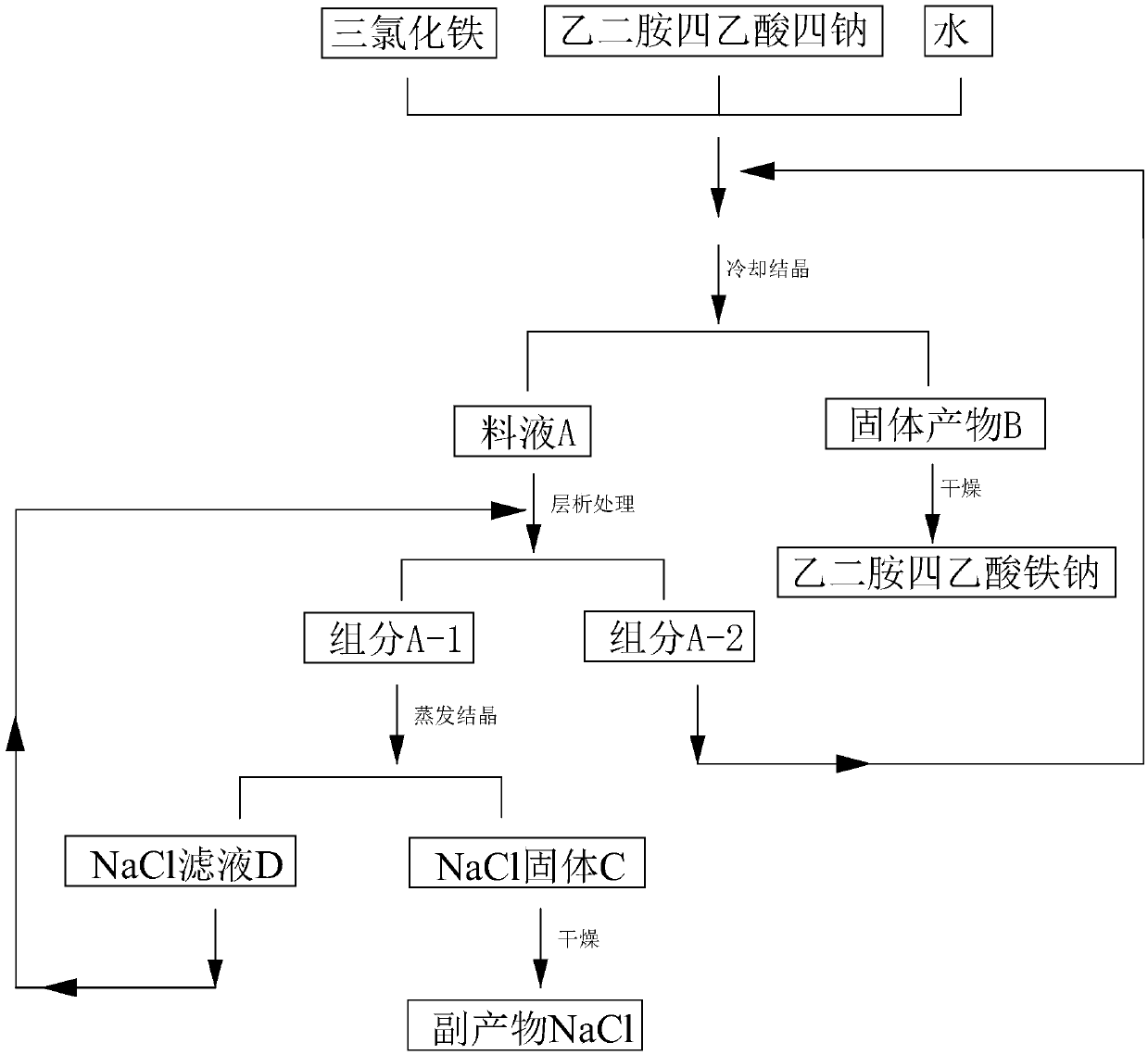

[0041] A kind of production method of ferric sodium edetate, such as figure 1 shown, including the following steps:

[0042] S1. Preliminary reaction: Add ferric chloride, tetrasodium ethylenediaminetetraacetic acid and water into the reactor at a molar ratio of 1:1:25, react for 1 hour, and the reaction is completed to obtain the raw material solution, and then the raw material solution is mixed at 10 Cooling and crystallization at a temperature of ℃ for 1.5h. The cooling and crystallization process can be realized in a cooling crystallizer. After the crystallization is completed, the first separation operation is performed to obtain feed liquid A and solid product B. In this step, the first separation operation can be a filtration operation, or It can be a centrifugal separation operation;

[0043]Specifically, when the first separation operation is a filtration operation, the raw material liquid after cooling and crystallization is filtered in a filter with a mesh size of ...

Embodiment 2

[0054] A kind of production method of ferric sodium ethylenediamine tetraacetate, carry out difference according to the method in embodiment 1 and be,

[0055] S1. Preliminary reaction: Add ferric chloride, tetrasodium ethylenediaminetetraacetic acid and water into the reactor at a molar ratio of 1:1.5:30, react for 100 minutes, and obtain the raw material liquid after the reaction is completed, and then put the raw material liquid at 18 Cool and crystallize at a temperature of 105min for 105min. The cooling crystallization process can be realized in a cooling crystallizer. After the crystallization is completed, the first separation operation is performed to obtain feed liquid A and solid product B. The first separation operation here can be a filtration operation or is a centrifugal separation operation;

[0056] S2, including solid product B processing S2-1 and feed liquid A processing S2-2, step S2-1 operates solid product B to obtain the desired final product sodium ferri...

Embodiment 3

[0064] A kind of production method of ferric sodium ethylenediamine tetraacetate, carry out difference according to the method in embodiment 1 and be,

[0065] S1. Preliminary reaction: Add ferric chloride, tetrasodium ethylenediaminetetraacetic acid and water into the reactor at a molar ratio of 1:2:35, react for 2 hours, and the reaction is completed to obtain the raw material solution, and then put the raw material solution at 25 Cooling and crystallization at a temperature of °C for 2 hours, the cooling crystallization process can be realized in a cooling crystallizer, and the first separation operation is performed after the crystallization is completed to obtain the feed liquid A and the solid product B. The first separation operation here can be a filtration operation or is a centrifugal separation operation;

[0066] S2, including solid product B processing S2-1 and feed liquid A processing S2-2, step S2-1 operates solid product B to obtain the desired final product so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com