A method for preparing a frosted surface on a Zr-based bulk amorphous alloy

A technology of zirconium-based amorphous alloys and amorphous alloys, which is applied to the field of preparing frosted surfaces on Zr-based bulk amorphous alloys, can solve the problems of amorphous alloy relaxation crystallization, impurities, and damage to the matrix performance, and reach the synthesis temperature The effect of low, uniform sanding and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

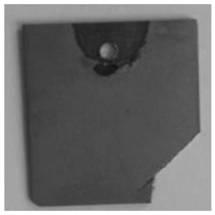

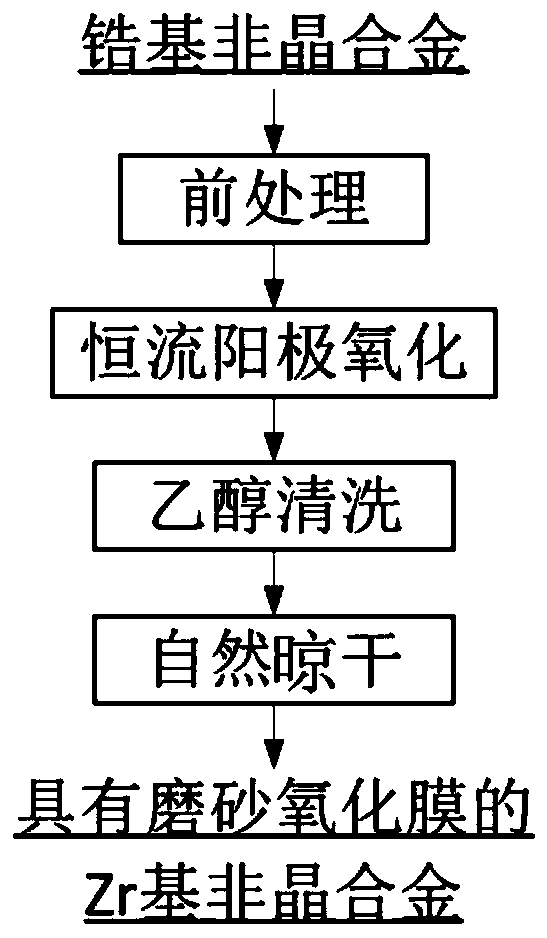

[0028] Such as figure 1 As shown, the zirconium-based amorphous alloy sheet after pretreatment (such as figure 2 Shown) as the anode, the cathode is a platinum sheet, the cathode and anode are placed in the electrolyte, at a temperature of 20°C and a current density of 14mA / cm 2 1. Carry out anodic oxidation under the condition that the electrolysis time is 30 minutes, take out the anode alloy sheet and dry naturally after ethanol cleaning, can prepare frosted surface on the zirconium-based amorphous alloy (such as image 3 shown). Among them, the cathode area of the platinum sheet is 1.5 times that of the anode area of the alloy sheet, and the electrolyte used is composed of NH 4 F and Na 2 SO 4 Prepared by dissolving in water, NH 4 F and Na 2 SO 4 The molar ratio after dissolution is 2:10, F - The concentration is 0.4mol / L.

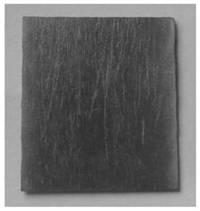

[0029] The surface of the zirconium-based amorphous alloy prepared in this example has a frosted structure, and the structure of the oxid...

Embodiment 2

[0031] Such as figure 1 As shown, the zirconium-based amorphous alloy sheet after pretreatment is used as the anode, and the cathode is a graphite plate. 2 1. Carry out anodic oxidation under the condition that the electrolysis time is 30 minutes, take out the anode alloy sheet, wash it with ethanol, and then dry it naturally, so that a frosted surface can be prepared on the zirconium-based amorphous alloy. Among them, the graphite cathode area is equal to the alloy sheet anode area, and the electrolyte used is composed of NH 4 F and Na 2 SO 4 Prepared by dissolving in water, NH 4 F and Na 2 SO 4 The molar ratio after dissolution is 2:10, F - The concentration is 0.5mol / L.

[0032] The surface of the zirconium-based amorphous alloy prepared in this example has a frosted structure, and the structure of the oxide film layer is dense, the frosting is uniform, and the surface is light gray.

Embodiment 3

[0034] Such as figure 1 As shown, the zirconium-based amorphous alloy sheet after pretreatment is used as the anode, and the cathode is a platinum sheet. 2 1. Carry out anodic oxidation under the condition that the electrolysis time is 25 minutes, take out the anode alloy sheet, wash it with ethanol, and then dry it naturally, so that a frosted surface can be prepared on the zirconium-based amorphous alloy. Among them, the cathode area of the platinum sheet is 1.5 times that of the anode area of the alloy sheet, and the electrolyte used is composed of NH 4 F and Na 2SO 4 Prepared by dissolving in water, NH 4 F and Na 2 SO 4 The molar ratio after dissolution is 3:10, F - The concentration is 0.6mol / L.

[0035] The surface of the zirconium-based amorphous alloy prepared in this example has a frosted structure, and the structure of the oxide film layer is dense, the frosting is uniform, and the surface is light gray.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com