Preparation method of porous carbon-coated antimony telluride nanosheet and application thereof as negative electrode material of metal ion battery

A technology of antimony telluride nanometers and nanosheets, which is applied in the field of nanomaterials, can solve problems such as volume expansion, shape destruction, and batteries that cannot have cycle performance, and achieve improved ion conductivity, simple preparation methods, and excellent electrochemical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

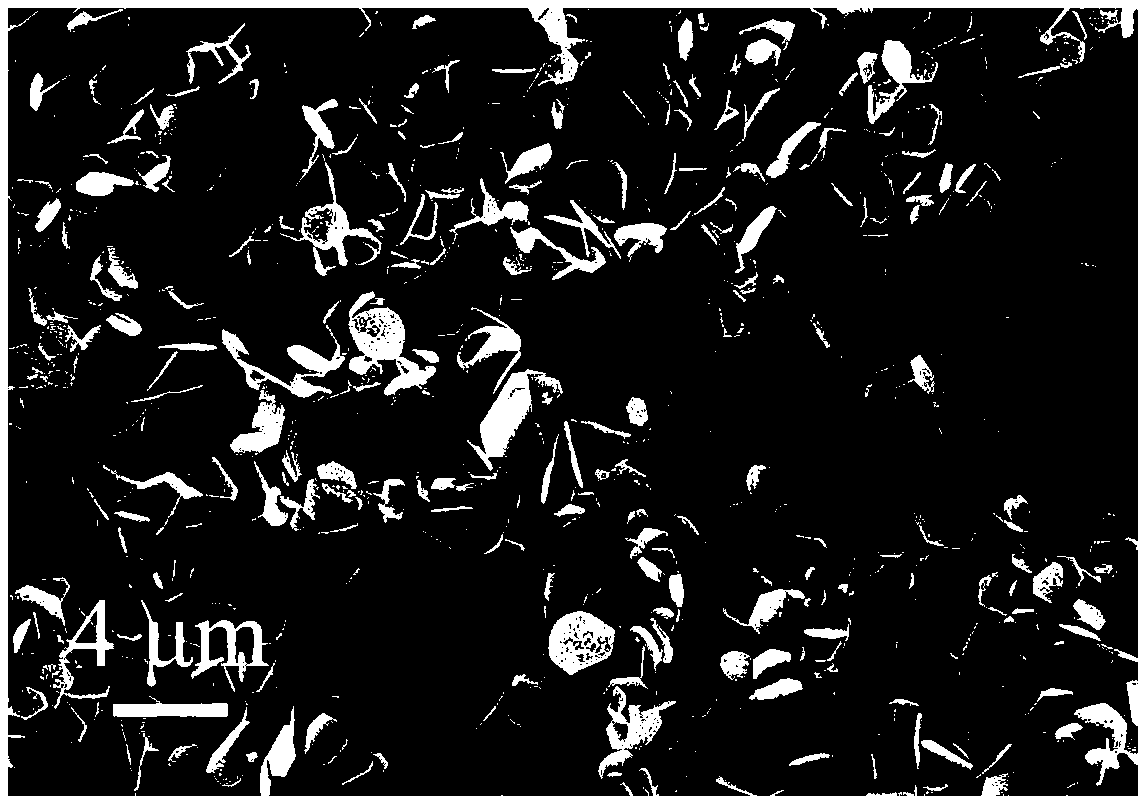

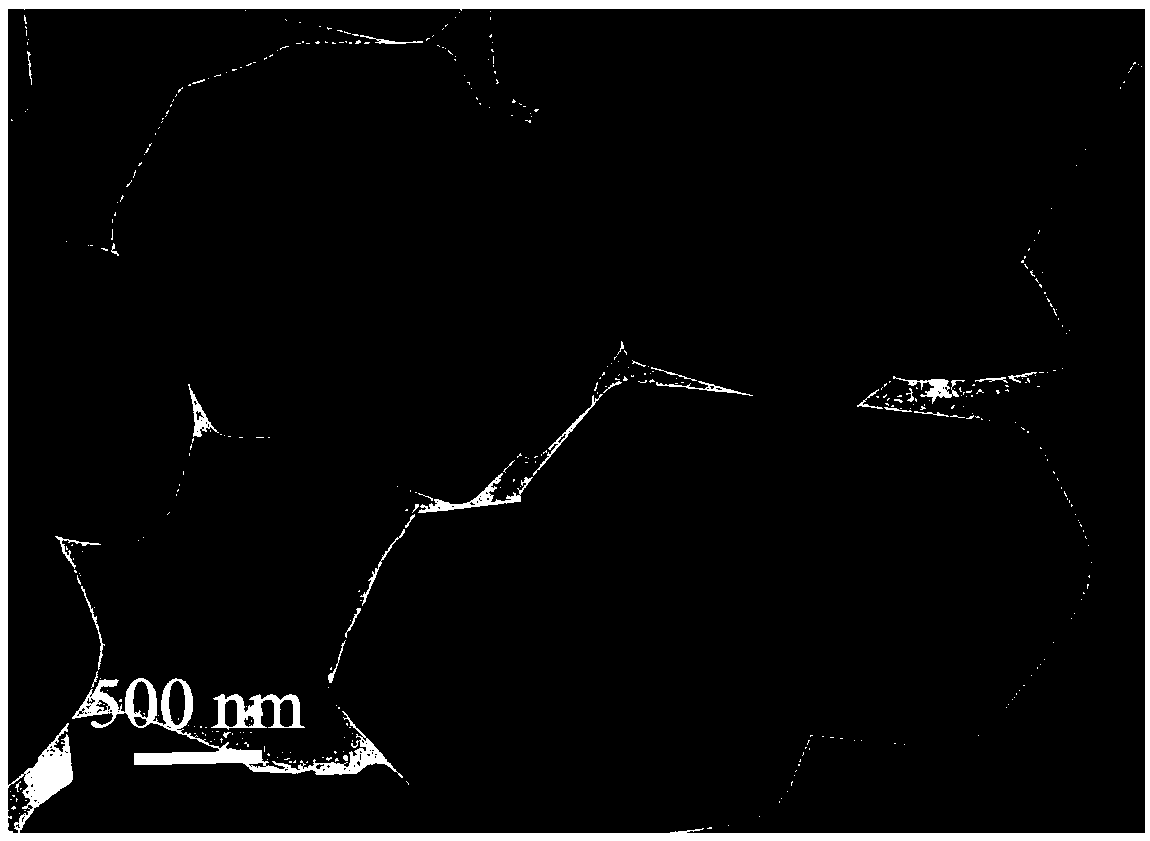

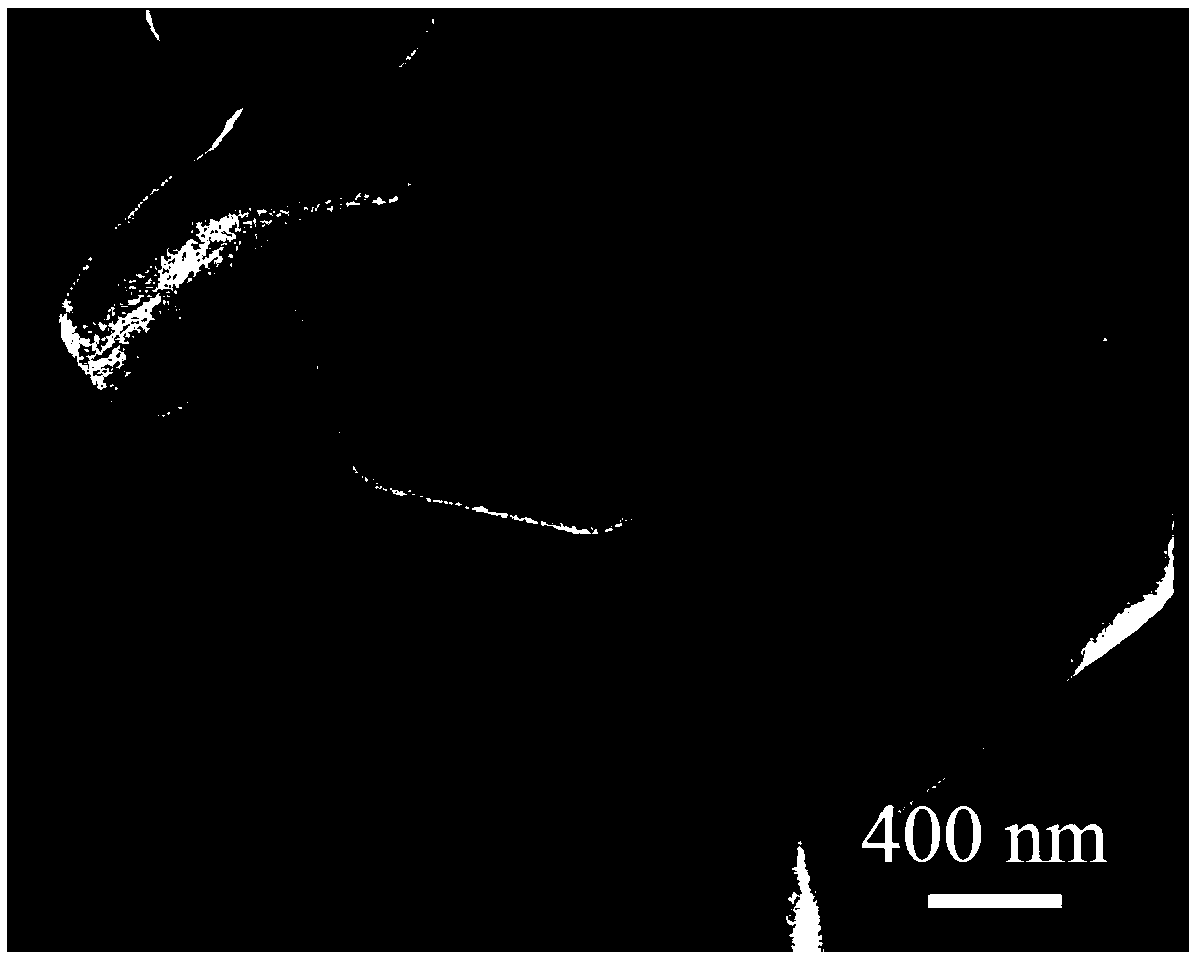

[0037] Step 1: Weigh 22.4mg antimony trichloride (SbCl 3 ), 0.4g of tartaric acid (TA) were dissolved in 6mL of distilled water, and then 31.5mg of sodium tellurite (Na 2 TeO 3 ), 20mL of ammonia water and 8mL of hydrazine hydrate, stirred for 6min, put into the reaction kettle, and reacted at 180°C for 5h, the obtained product was washed with distilled water and absolute ethanol several times, and dried under vacuum to obtain Sb 2 Te 3 Nanosheets;

[0038] Step 2: Add 60mg Sb 2 Te 3 Add the nanosheets into a mixture of 35mL ethanol and 24mL water, and disperse evenly by ultrasonication, then add 108mg cetyltrimethylammonium bromide (CTAB), stir for 10min, continue to add 60mg resorcinol, 120μL ammonia water and 50μL formaldehyde solution, stirred and reacted at room temperature for 16 hours; after the reaction, the resulting product was washed with distilled water and absolute ethanol several times, and dried under vacuum conditions to obtain Sb 2 Te 3 @RF Nanosheet; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com